Containment local component strength test device

A strength test and containment technology, applied in the direction of measurement device, strength characteristics, and the use of stable tension/pressure to test the strength of materials. and other problems, to achieve the effect of low cost, convenient disassembly, and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

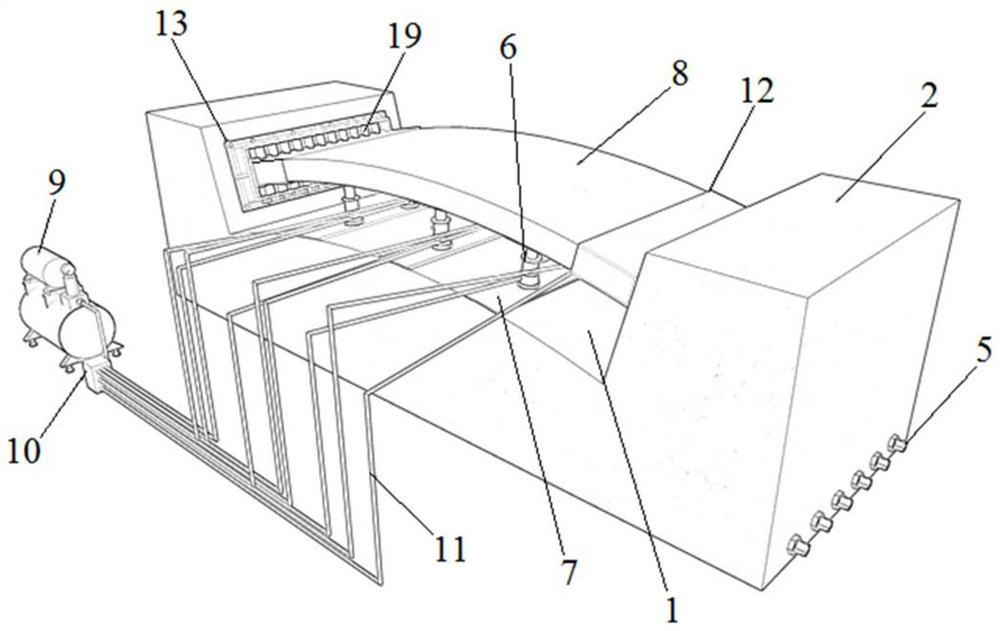

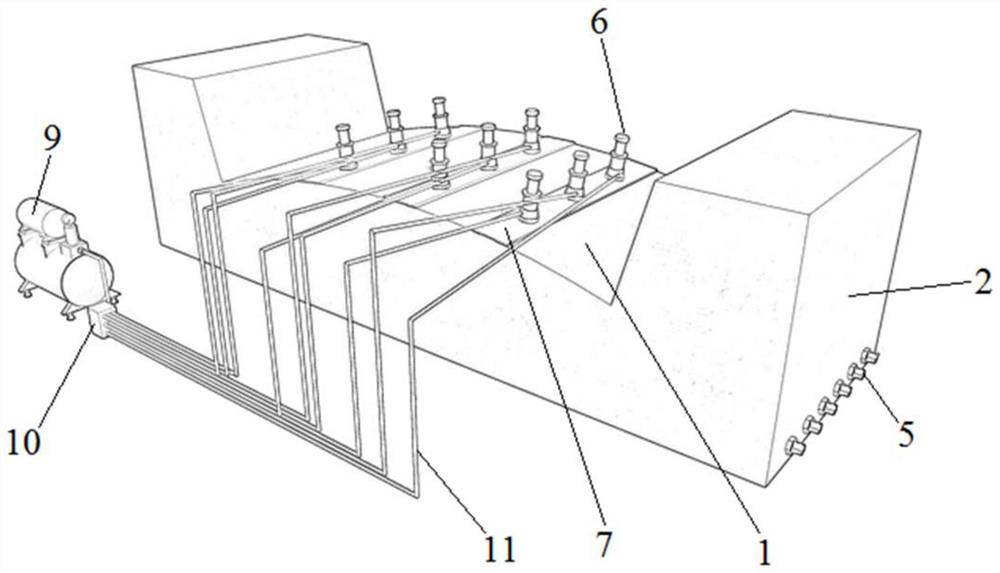

[0041] Such as figure 1 The strength test device for local components of the containment shown in the figure includes a rigid reaction base, a radial actuator group, a hydraulic oil loading mechanism, and a pair of circumferential sliding support mechanisms. The rigid reaction base is provided with an actuator The actuator group placement slot 1, the radial actuator group is set in the actuator group placement slot 1, and is connected with the hydraulic oil loading mechanism, and a pair of annular sliding support mechanisms are respectively arranged in the actuator group placement slot 1 opposite on both side walls.

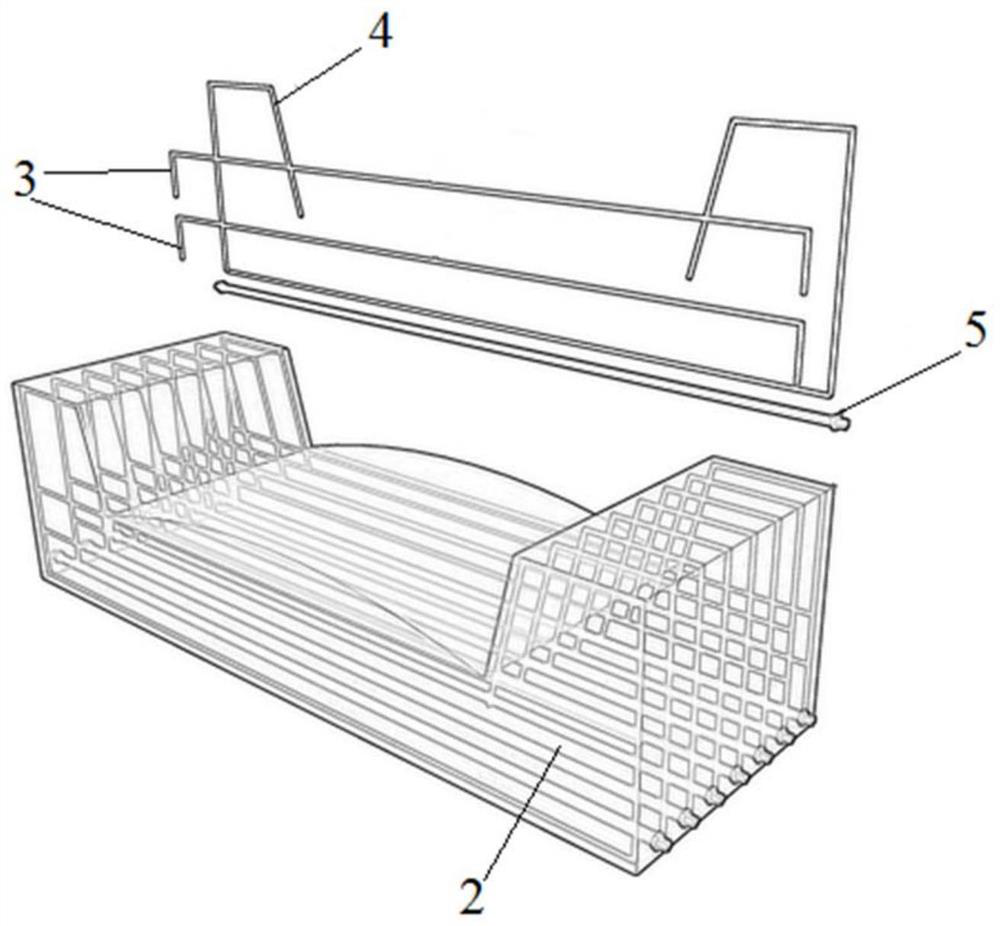

[0042] Such as figure 2 As shown, the rigid reaction base includes a base body 2 and longitudinal bars 3, stirrups 4, and prestressed reinforcement bars 5 that are respectively arranged inside the base body 2. The prestressed reinforcement bars 5 are arranged at the bottom of the base body 2. The ribs 3 and stirrups 4 are arranged in full section along the ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com