Test method and device based on rock uniaxial compression

A uniaxial compression and test method technology, applied in measuring devices, using stable tension/pressure testing materials, instruments, etc., can solve problems such as reducing the degree and possibility of rock bursts, and achieve stable pressure and gas state. , the effect of reducing air pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

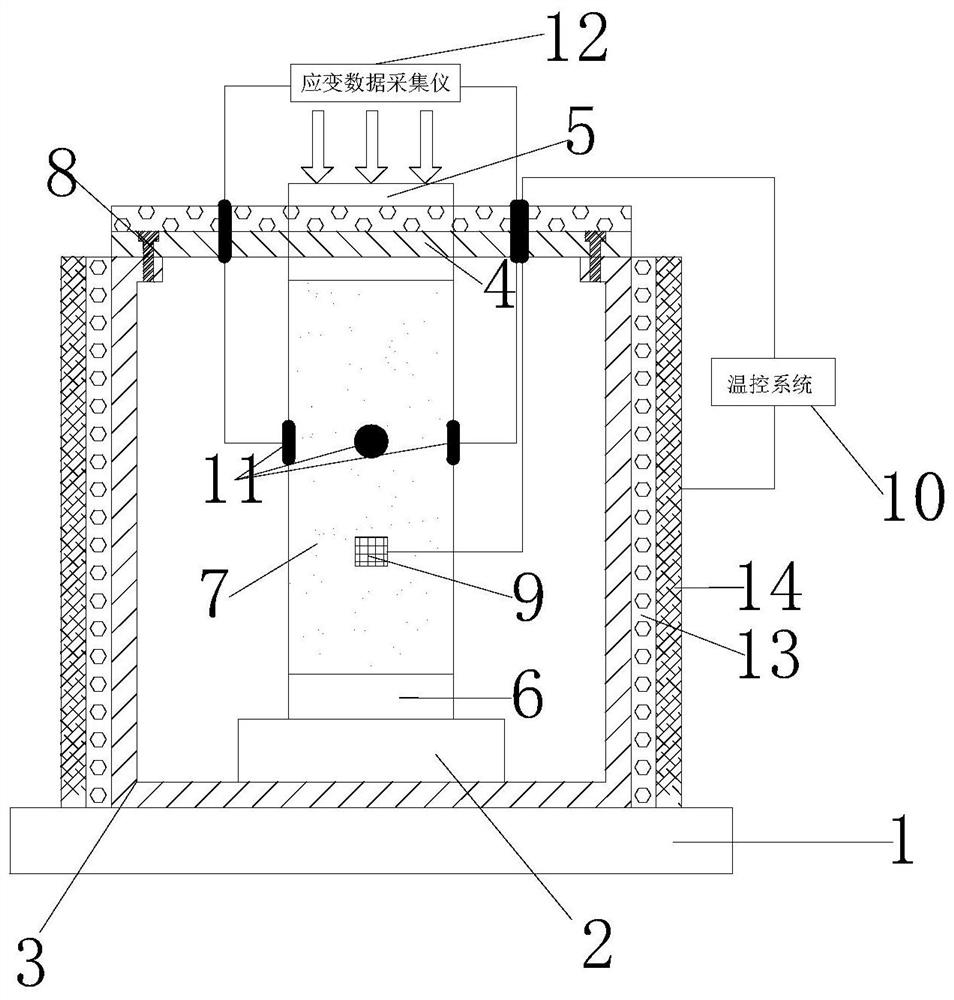

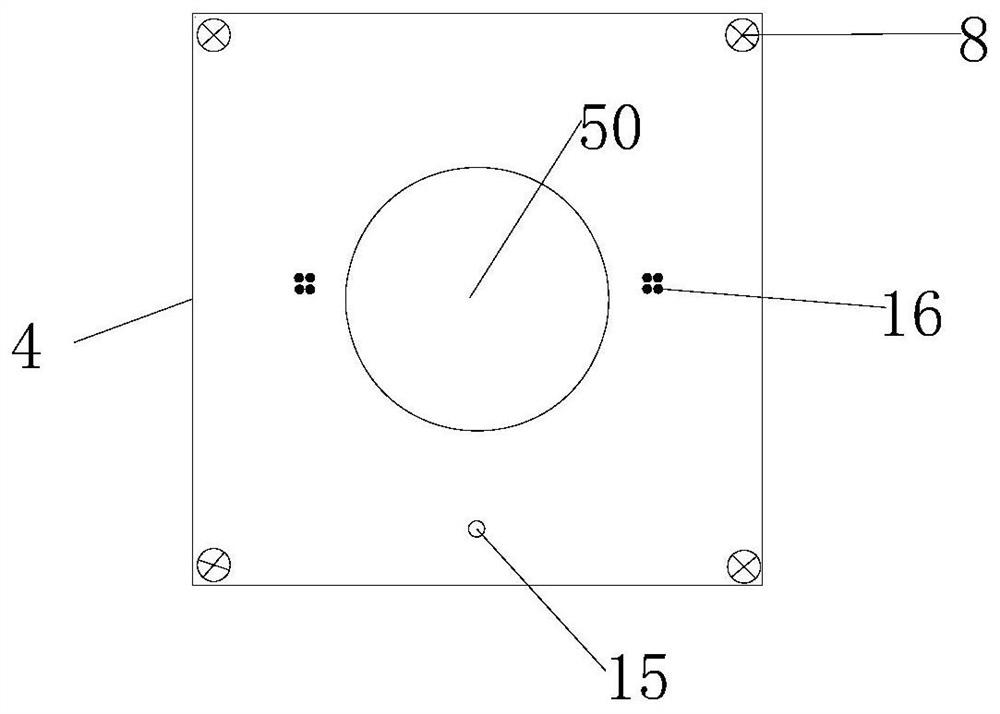

[0034] Such as figure 1 As shown, a kind of test device based on rock uniaxial compression of the present invention, comprises the sealing test box 3 that places on the platform 1, is provided with base 2, upper cushion block 5, lower cushion block 6 and The rock sample 7, the rock sample 7 is placed on the lower block 6, the upper block 5 is placed on the top of the rock sample 7, and the load is applied on the upper block 5 to deform the rock sample 7. The rock sample 7 is provided with a stress-strain sensing sheet 11 and a temperature sensing sheet 9 , the stress-strain sensing sheet 11 is connected to a stress-strain data acquisition instrument 12 , and the temperature sensing sheet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com