A method and system for automatic inspection management based on operation and maintenance services

An automatic patrol inspection and management system technology, applied in inspection time and patrol, etc., can solve problems that affect the application effect of self-service terminals, consume a lot of manpower and material resources, and operation and maintenance inspections are not in place, so as to achieve inspection prevention and management , Realize automation and ensure the effect of operation and maintenance service quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

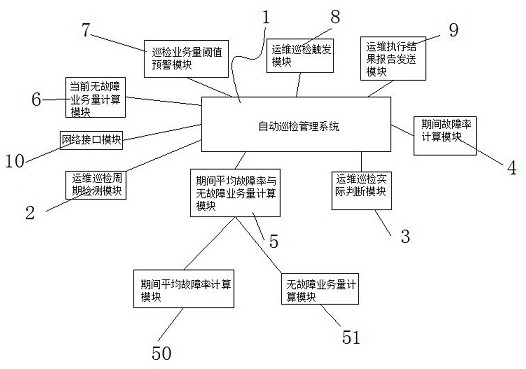

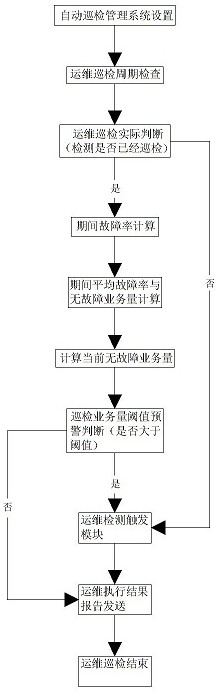

[0033] example, see appendix Figure 1 to Figure 2 , a method for automatic inspection management based on operation and maintenance services, comprising the following steps:

[0034] (1) Setting of the automatic inspection management system 1: Install the automatic inspection management system 1 on the automatic service terminal, and the automatic inspection management system 1 includes an operation and maintenance inspection cycle detection module 2, an operation and maintenance inspection actual Judgment module 3, period failure rate calculation module 4, period average failure rate and no-fault business volume calculation module 5, current no-fault business volume calculation module 6, inspection business volume threshold early warning module 7, operation and maintenance inspection trigger module 8 and an op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com