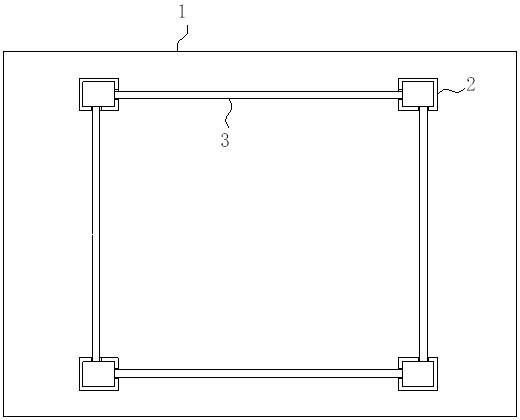

Device and method for preventing wire pipe from being blocked

A wire tube and sealing device technology, which is applied in the direction of cable installation, cable installation devices, electrical components, etc., can solve the problems of insufficient consideration of threading, inability to reverse bend, difficult threading, etc., to solve threading blockage, increase The effect of firmness and reduction of construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

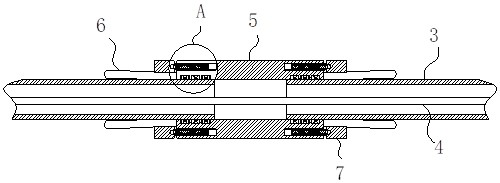

[0043] As a specific embodiment of the present invention, the sealing device includes a plurality of piston rings 14, the inner walls of the tube 5 near both ends are provided with sealing grooves 15 matching the piston rings 14, and the inner walls of the piston rings 14 are Both the surface of the ring and the outer ring are provided with a groove 16, and the inside of the groove 16 is provided with a water-stop rubber 17, and a sealing device is provided, which is beneficial to pass through the piston ring 14 and the water-stop rubber 17, and the pipe barrel 5 and the line pipe 3 are sealed to prevent the moisture of the concrete from entering the inside of the line pipe 3 during pouring of concrete, causing moisture inside the line pipe 3 and affecting the safety of electric wires.

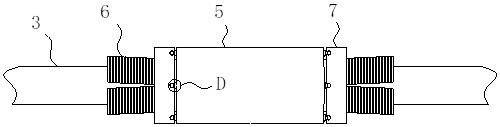

[0044] As a specific embodiment of the present invention, the thickness of the arc-shaped threaded plate 6 between the end close to the tube 5 and the end away from the tube 5 is set to increas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com