Melon seed batch shelling equipment

A batch and equipment technology, applied in the direction of shelling, food processing, pod removal, etc., can solve the problems of labor, boredom, low work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

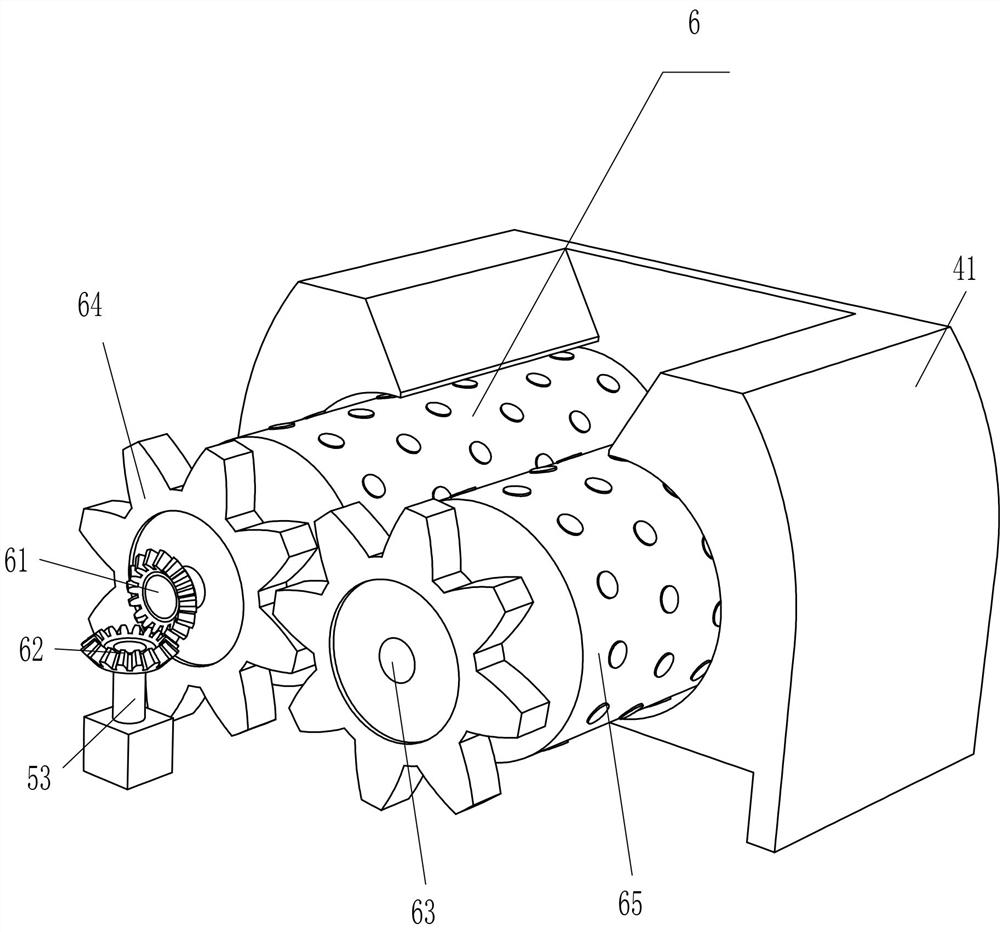

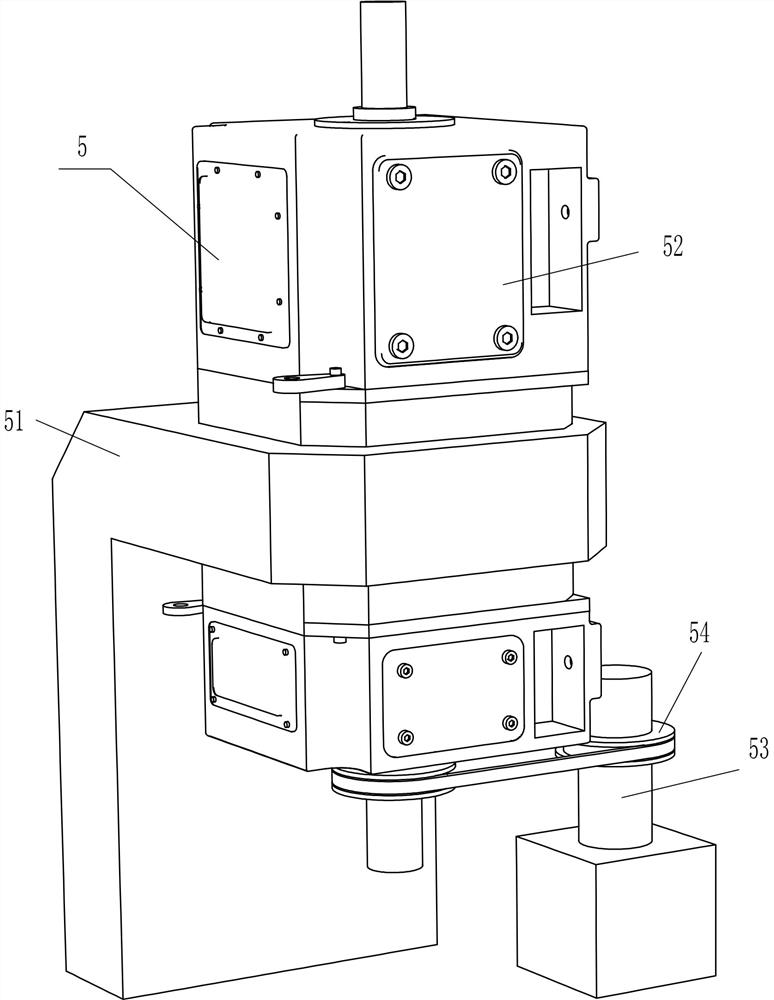

[0028] A kind of batch shelling equipment of melon seeds, such as Figure 1-Figure 4 As shown, it includes a base 1, a column 2, a mounting plate 3, a material storage device 4, a driving device 5 and a shelling device 6. The top of the base 1 is fixedly connected with four columns 2 at intervals, and the tops of the four columns 2 are fixedly connected. There is a mounting plate 3, the mounting plate 3 is provided with a material storage device 4, the material storage device 4 is provided with a driving device 5, and a shelling device 6 is provided between the driving device 5 and the material storage device 4.

[0029] The material storage device 4 includes a lower material cylinder 41, a vertical plate 42, a feed hopper 43, a blower fan 44 and a fixed plate 45, and the right side of the top of the mounting plate 3 is fixedly connected with the lower material cylinder 41, and the top of the lower material cylinder 41 is symmetrically fixed. Connect with riser 42, front and b...

Embodiment 2

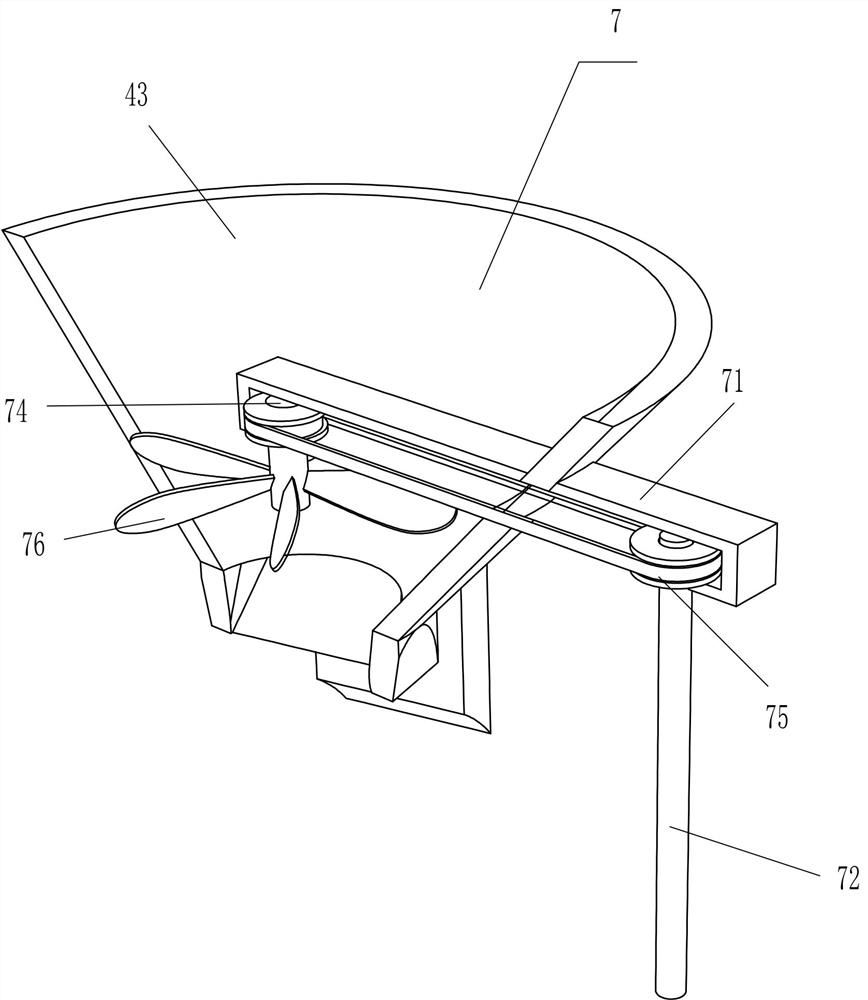

[0037] On the basis of Example 1, such as figure 1 , Figure 5 , Image 6 and Figure 7 As shown, a stirring device 7 is also included, and the stirring device 7 includes an outer mounting block 71, a first connecting shaft 72, a fourth rotating shaft 74, a second transmission assembly 75 and a stirring fan blade 76, and the feeding hopper 43 is left The outer mounting block 71 is fixedly connected to the outer mounting block 71. The left part of the outer mounting block 71 is rotatably provided with a first connecting shaft 72. The bottom end of the first connecting shaft 72 is fixedly connected with the upper output shaft of the biaxial motor 52. The outer mounting block 71 right The rotary type is provided with a fourth rotating shaft 74, and a second transmission assembly 75 is connected between the upper circumferential direction of the first connecting shaft 72 and the upper circumferential direction of the fourth rotating shaft 74, and the stirring fan blades 76 are f...

Embodiment 3

[0042] On the basis of embodiment 1 and embodiment 2, such as figure 1 , Image 6 and Figure 8 As shown, ash blocking device 9 is also included, and gray blocking device 9 includes vertical plate 91, inclined baffle plate 92 and transverse baffle plate 93, base 1 top rear side is symmetrically provided with vertical plate 91, vertical plate 91 outer front side A slanted baffle 92 is fixedly connected, and a transverse baffle 93 is fixedly connected between the front parts of the slanted baffles 92 on the left and right sides.

[0043] Also includes a guide 10, the guide 10 includes a vertical block 101, a guide plate 102 and a perforated plate 103, the right side of the top of the base 1 is symmetrically fixed with a vertical block 101, and the upper parts of the vertical blocks 101 on the front and rear sides are fixed. A guide plate 102 is arranged, and the guide plate 102 is fixedly connected with the lower right side of the lower material cylinder 41 , and the right sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com