Body-building rowing machine

A rowing machine and casing technology, applied in sports accessories, muscle training equipment, gymnastics equipment, etc., can solve the problems of not meeting actual needs, uneven energy consumption, unfavorable physical exercise, etc., so as to improve exercise effect and reduce exercise pressure , the effect of preventing injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

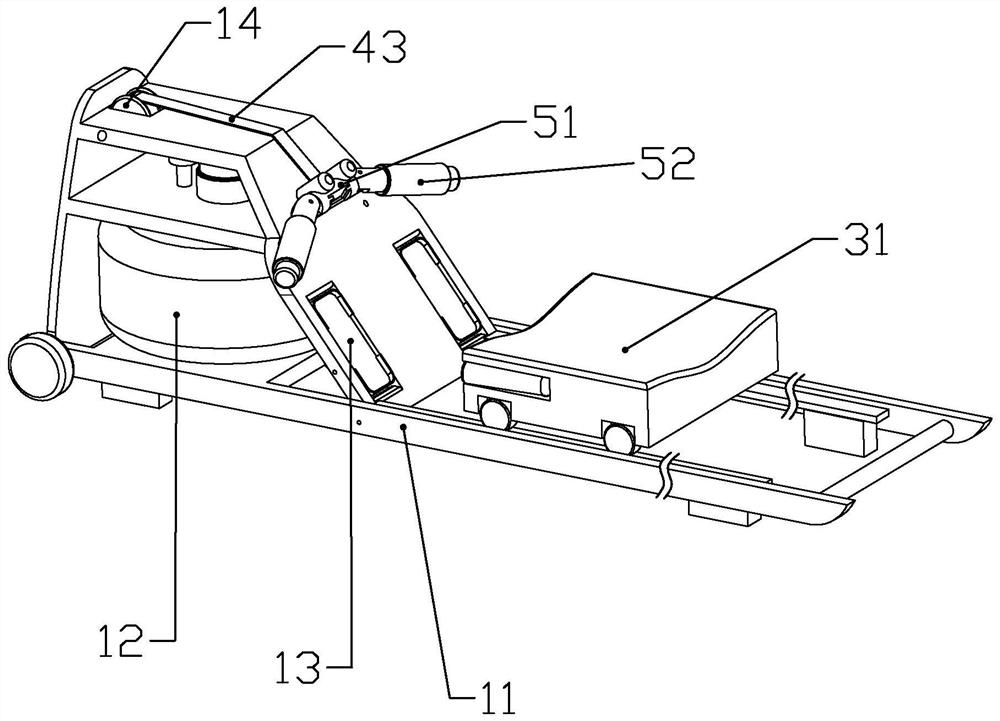

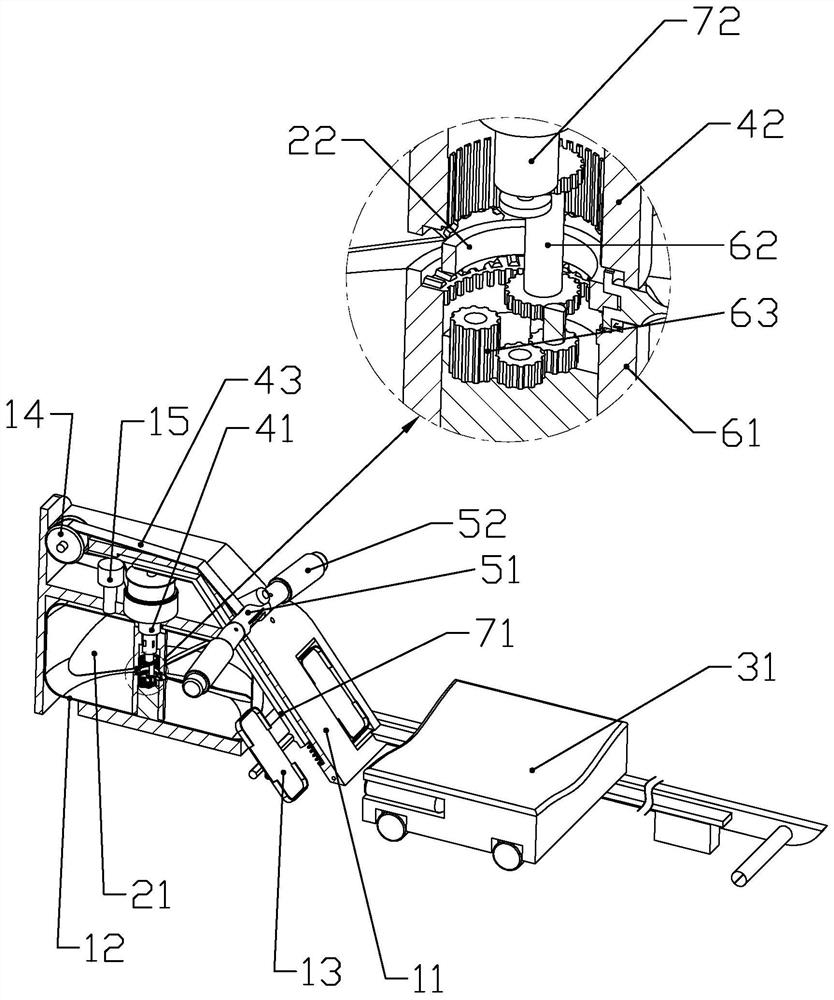

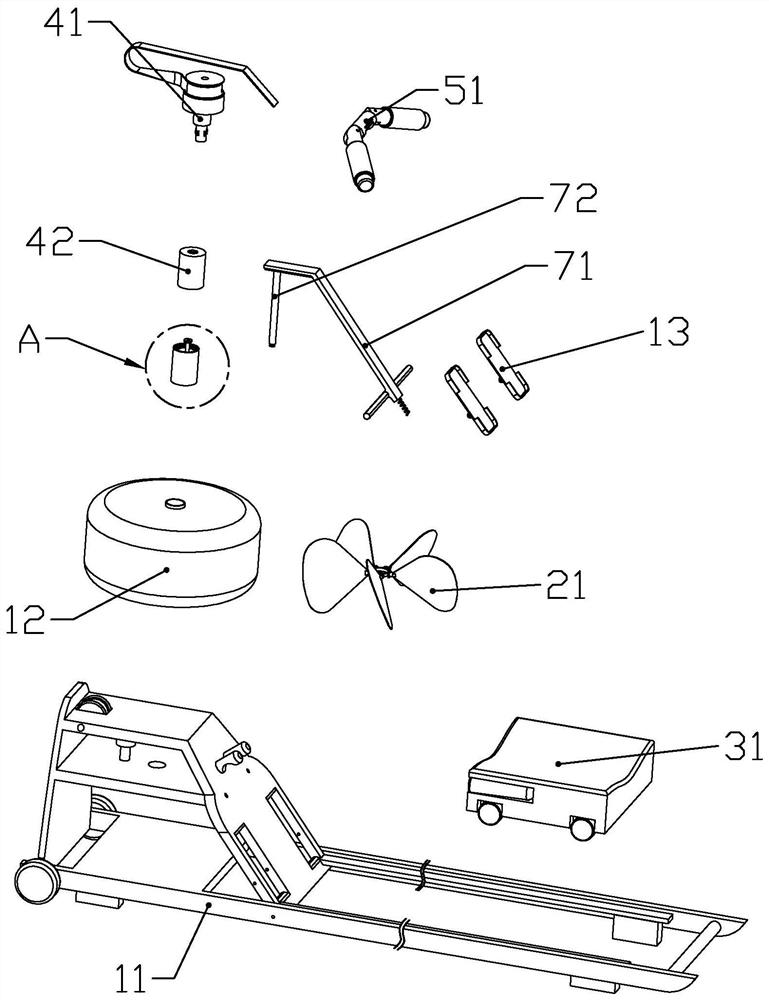

[0045] according to Figure 1 to Figure 14 As shown, a fitness rowing machine described in this embodiment includes a frame body 11, a water tank 12 fixedly connected to the frame body 11 for holding water, and a water tank 12 that is slidably connected to the frame body 11 along the front and rear directions. The sliding seat 31 for the user to sit on; the middle and upper part of the water tank 12 is rotatably connected with a driving sleeve 42 arranged longitudinally on the rotating shaft; The drive sleeve 42 is one-way transmission-connected drive shaft 41; the upper end of the drive shaft 41 is provided with a drag belt 43 for driving the drive shaft 41 to rotate.

[0046] The front end of the frame body 11 is formed with two symmetrically arranged sliding rails 111 that are slidingly connected with the sliding seat 31; The sliding wheel set includes two symmetrically arranged sliding wheels 35 that abut against the corresponding slide rails 111 ; The moving wheels 16 a...

Embodiment 2

[0076] according to Figure 15 to Figure 17 As shown, the difference between this embodiment and Embodiment 1 is that: the inner wall of the driven sleeve 61 is located below the driven gear 612 and an outer differential gear 613 with a diameter smaller than the driven gear 612 is formed; An inner differential gear 621 capable of transmission connection with the outer differential gear 613 is formed at the central position of the lower end of the synchronous gear shaft 62 .

[0077] When the synchronous gear shaft 62 is at the first position, the synchronous gear shaft 62 is located at the upper limit position, the synchronous gear shaft 62 is in transmission connection with the driven gear 612, and the inner differential gear 621 is not connected with the driven gear 612. The outer differential gear 613 is connected by transmission, the driving sleeve 42 is rotated, the driving sleeve 42 is relatively fixed to the driven sleeve 61, and the rotation of the driving sleeve 42 dr...

Embodiment 3

[0081] according to Figure 18 As shown, this embodiment makes the following improvements on the basis of Embodiment 1: a tape take-up box 33 is provided at the center of one end of the sliding seat 31 toward the water tank 12; an extension belt 34 is provided in the tape take-up box 33 The end of the extension belt 34 away from the take-up box 33 is fixedly connected with the plug board 341; The extension belt 34 is wound into the torsion spring in the take-up box 33; the end of the pull rod 51 away from the drag belt 43 is formed with an insertion groove 511 capable of being inserted into the insertion plate 341; The left and right sides of the sliding seat 31 are rotationally connected with two symmetrically arranged second handles 32 ; the left and right sides of the sliding seat 31 are respectively formed with handle grooves 311 for accommodating the corresponding second handles 32 .

[0082] When using this product for waist and abdomen exercise, the frame body 11 is pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com