Voc industrial waste gas purification device

A purification device and industrial waste gas technology, applied in gas treatment, transportation and packaging, chemical instruments and methods, etc., can solve the problems of environmental damage, insufficient purification, and insufficient purification effect of waste gas, so as to save resources and improve purification effect , Improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

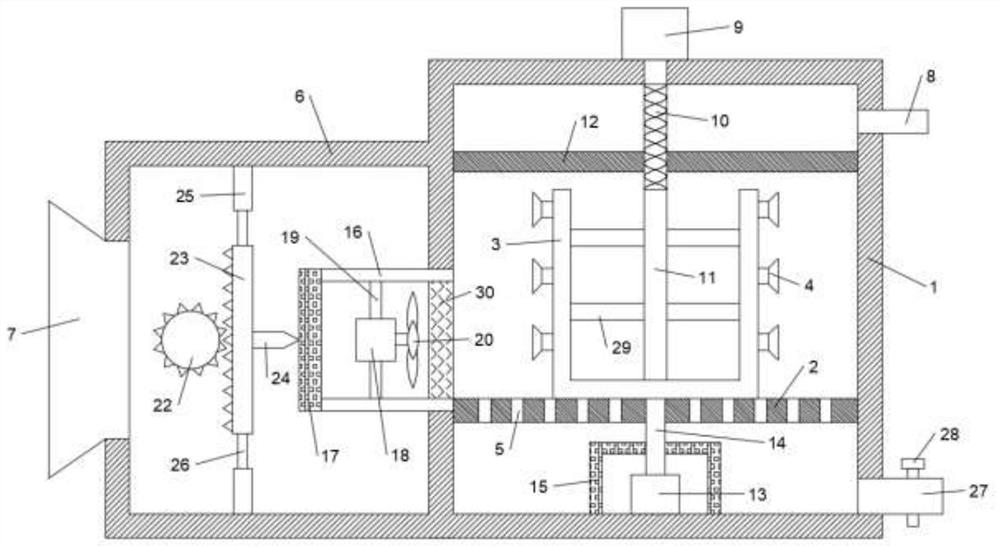

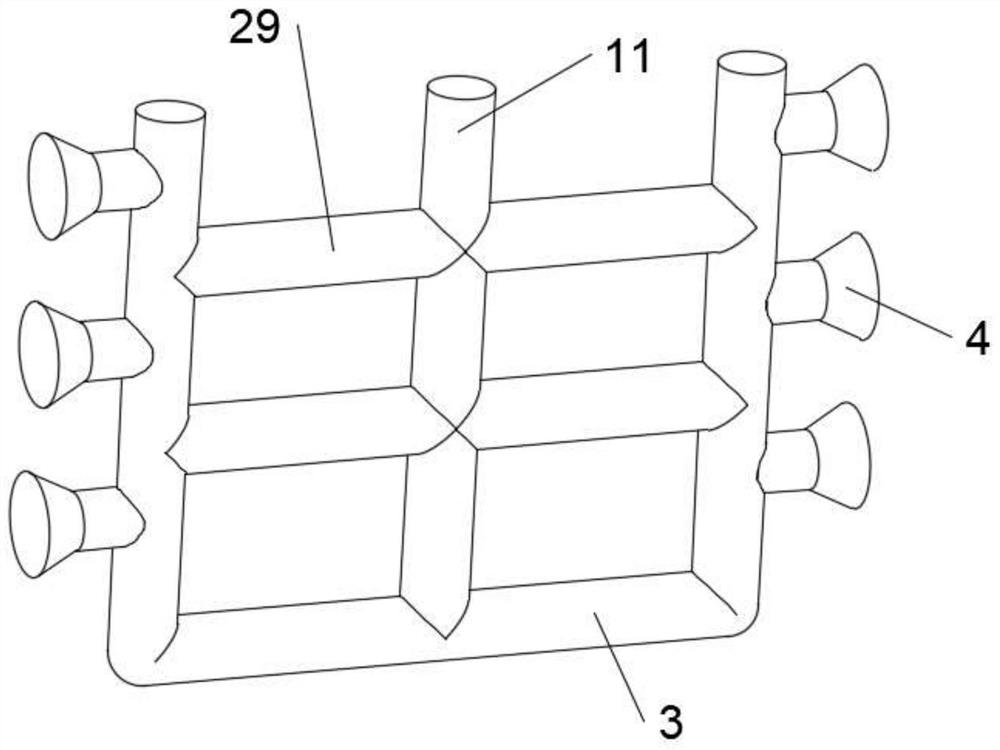

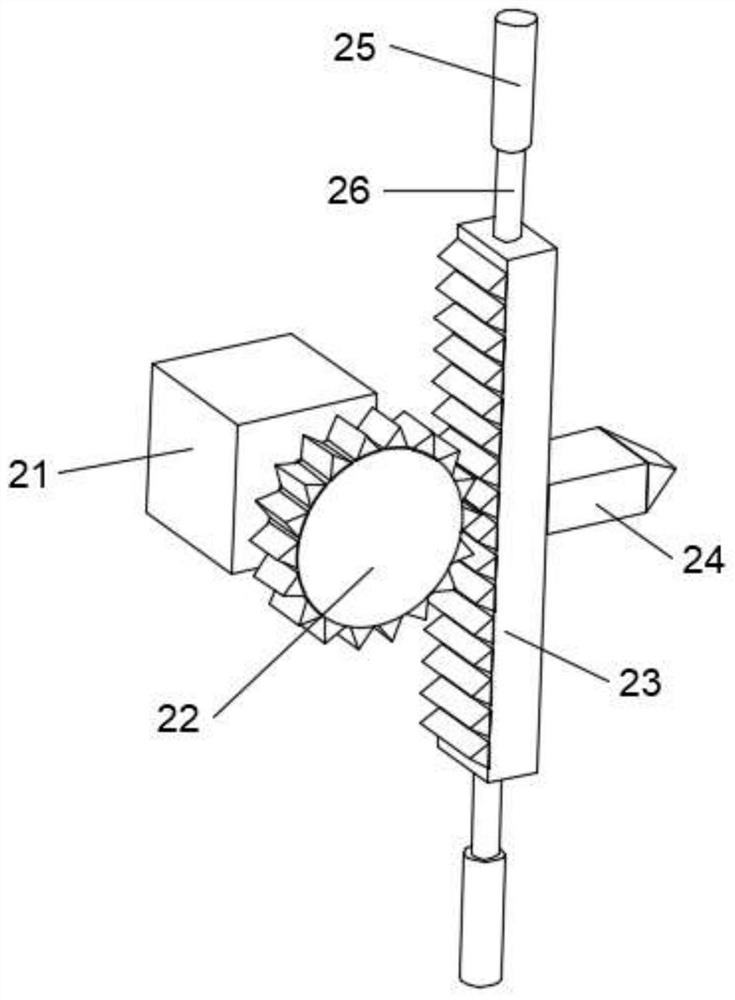

[0020] see Figure 1-3 , in the embodiment of the present invention, a voc industrial waste gas purification device includes a large box 1, a partition 2 is arranged inside the large box 1, and a plurality of evenly arranged through holes 5 are arranged on the partition 2, A nozzle 3 is arranged above the partition 2, a plurality of nozzles 4 are arranged on the side wall of the nozzle 3, a rotary extruding device is arranged inside the large box 1, and a nozzle is adjacently arranged on the left side wall of the large box 1. Small box body 6, the left end of the small box body 6 is provided with an air intake cylinder 7, and the left side wall of the large box body 1 is provided with an air suction device. The air suction device is located inside the small box body 6. In the large box 1, the purification liquid is sprayed out through the nozzle 4, and the rotary extrusion device is started, so that the nozzle 4 rotates and sprays the liquid, so that the exhaust gas and the pu...

Embodiment 2

[0028]In order to improve the purification effect of circulating the purified liquid, this embodiment is further improved on the basis of Embodiment 1. The improvement is: a filter screen 15 is arranged on the outside of the water pump 13, and through the filter screen 15, the water entering the The purification liquid in the water pipe 14 is filtered to improve the purification effect of the purification liquid and further improve the purification efficiency of the waste gas.

[0029] The working principle of this embodiment is: in order to improve the purification effect of circulating the purified liquid, a filter screen-15 is arranged on the outside of the water pump 13, and the purified liquid entering the water pipe 14 can be filtered through the filter screen-15. Improve the purification effect of the purification liquid, and then improve the purification efficiency of the exhaust gas.

[0030] To sum up, by setting the rotary extruding device, the nozzle 4 is rotated t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com