Engine oil filter element recovery pretreatment device capable of realizing quick separation

A pretreatment device and oil filter technology, which is applied in the field of oil filter element recycling pretreatment device, can solve problems such as waste of resources, low recycling efficiency, harmful to human body, etc., and achieve the effect of saving resources and improving recycling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

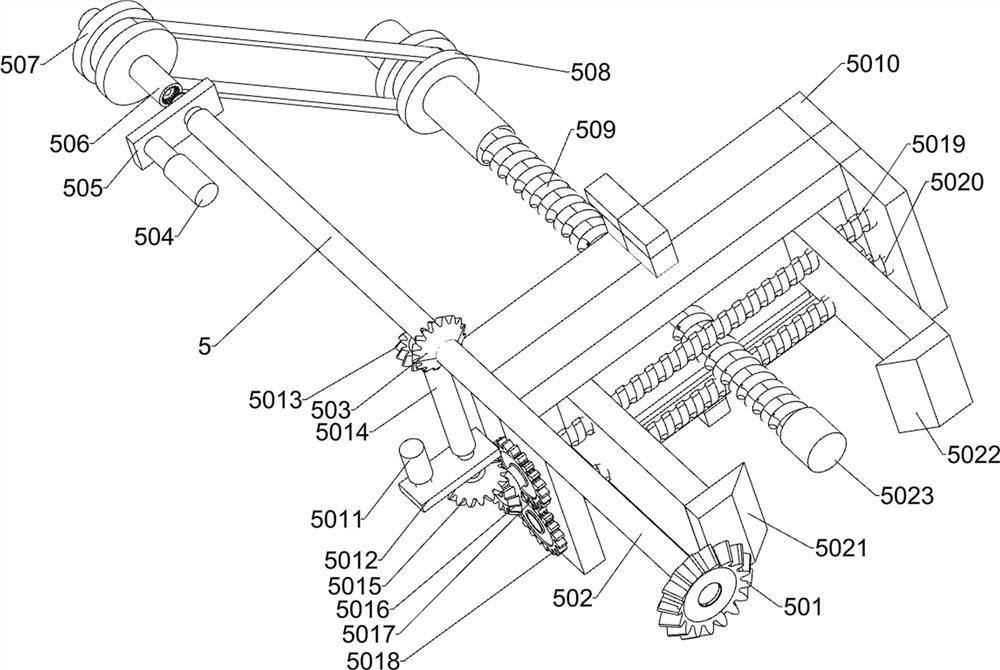

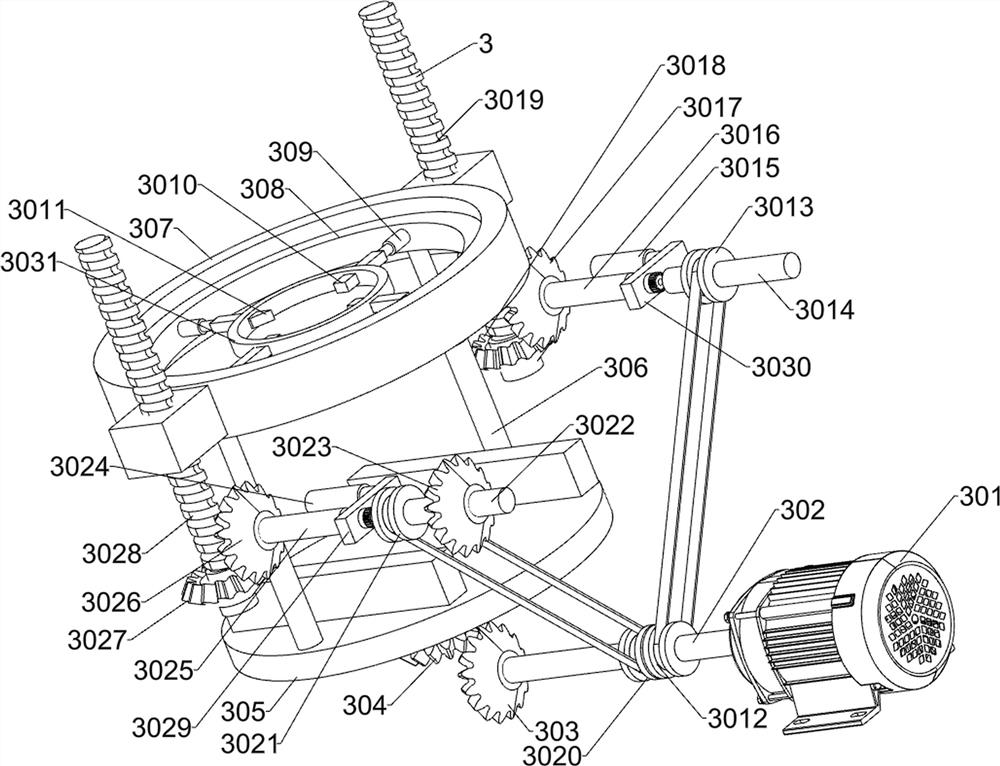

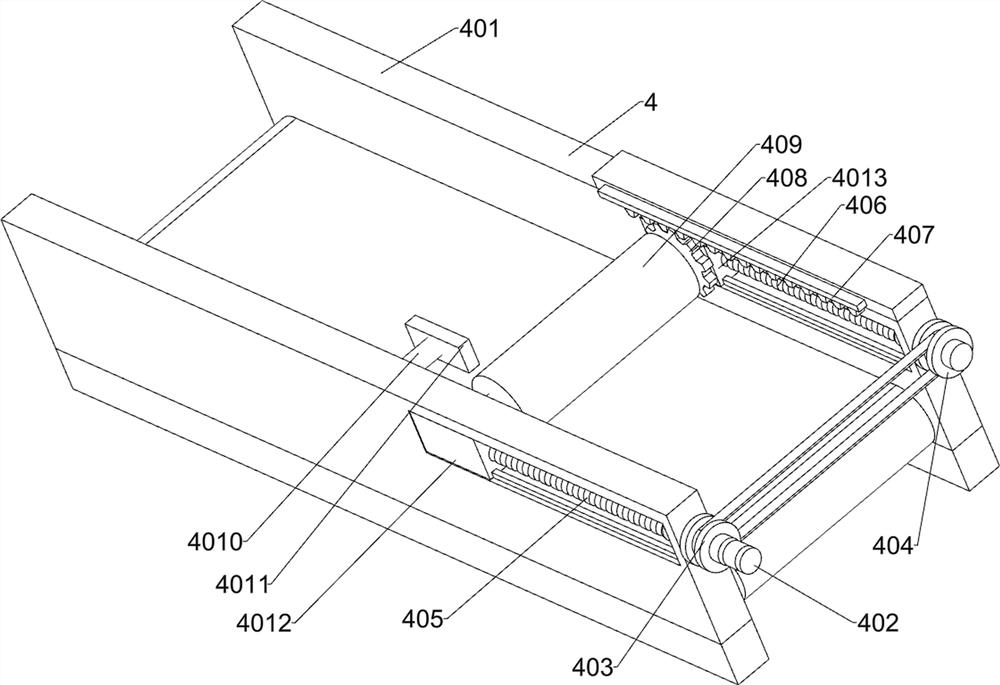

[0027] A quick-separate oil filter recovery pretreatment device, such as Figure 1-6 As shown, it includes a workbench 1, a control panel 2, a separation mechanism 3, a magnetic attraction mechanism 4, a fixing mechanism 5 and a feeding mechanism 6; the workbench 1 is connected to the control panel 2; the workbench 1 is connected to the separation mechanism 3 Workbench 1 is connected with magnetic attraction mechanism 4; Workbench 1 is connected with fixed mechanism 5; Workbench 1 is connected with feeding mechanism 6; Separation mechanism 3 is connected with fixation mechanism 5; One side of separation mechanism 3 is provided with The magnetic suction mechanism 4; the other side of the separation mechanism 3 is provided with a feeding mechanism 6.

[0028] Working principle: when the device is used, the oil filter element is manually placed on the feeding mechanism 6, and the device is opened and adjusted through the control panel 2, and then the upper cover of the filter ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com