Inner cavity extension periodic wave type non-pneumatic tire and processing method thereof

A technology of non-pneumatic tires and processing methods, which is applied to non-pneumatic tires, tire parts, tires, etc., and can solve problems such as puncture safety accidents and maintenance difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

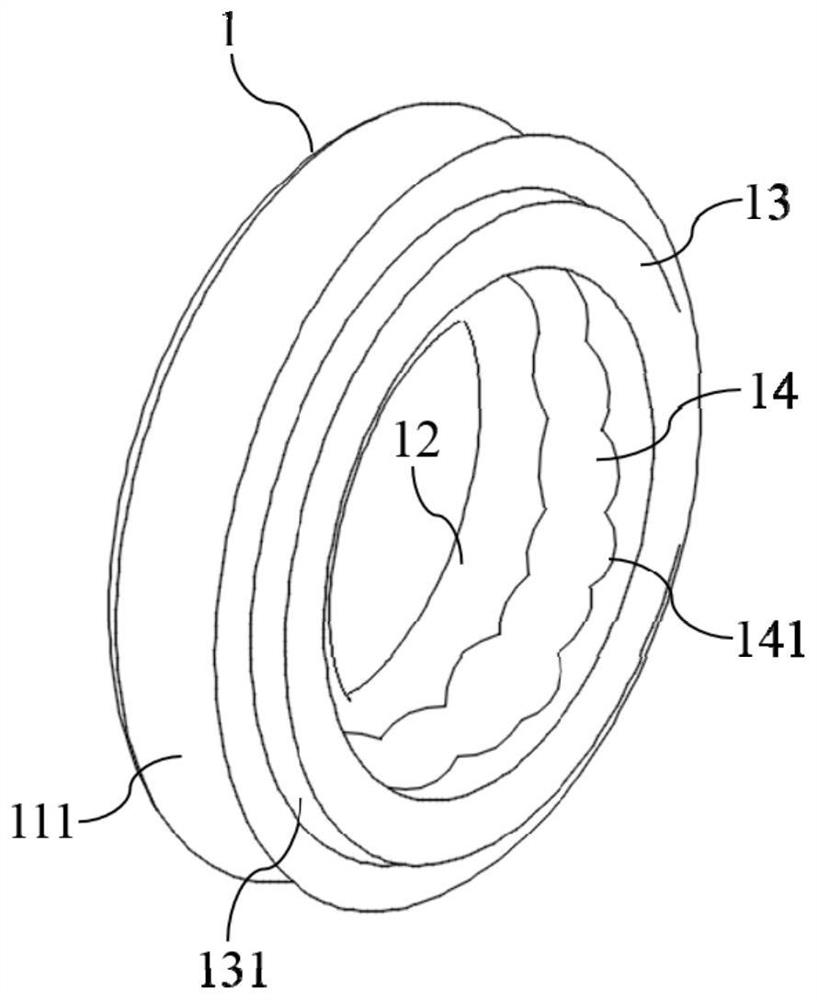

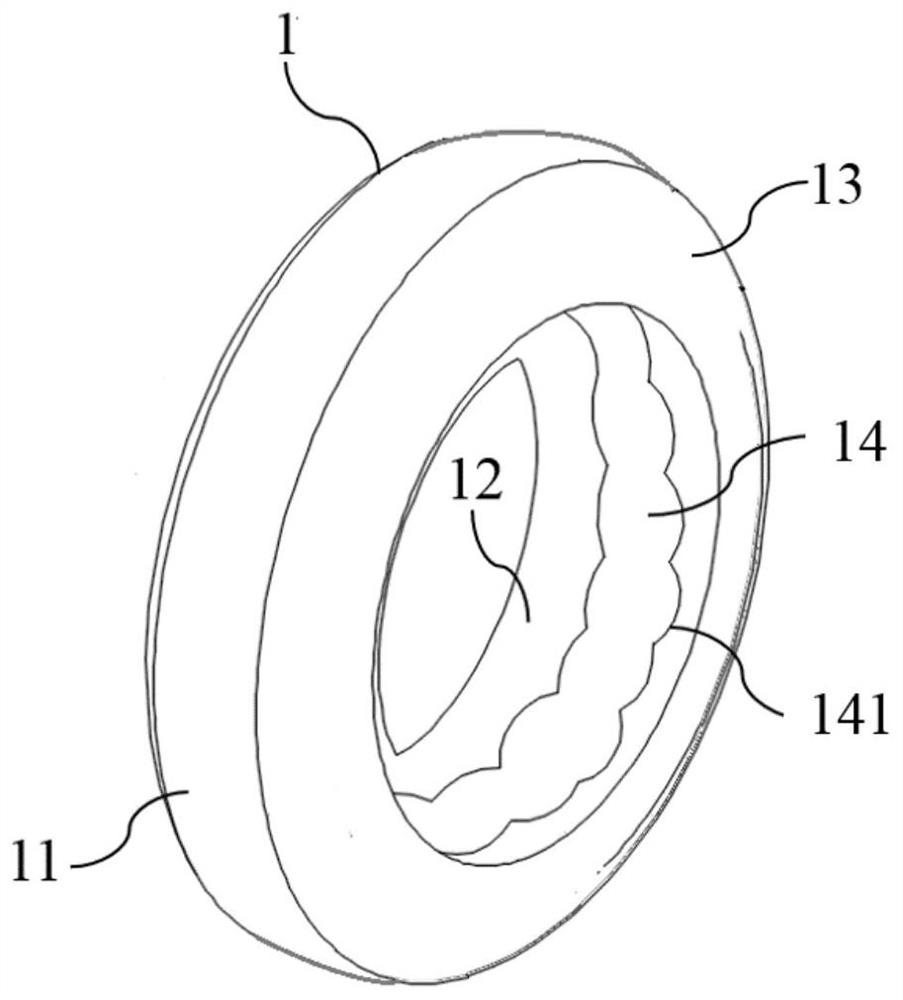

[0039] A kind of cavity extension periodical wave type non-pneumatic tire of the present embodiment, such as figure 2 As shown, it includes a tire billet 1 extruded by a screw extruder, and the tire billet 1 includes a crown 11 and a belly 12, as Figure 4~5The belly 12 is provided with belly grooves 121 along its circumference, and several groups of inner cavity grooves 14 are arranged at equal intervals along the circumference of the tire belly grooves 121. The inner cavity grooves 14 start and end connected to form an extended periodic wave-like cavity 141, such as Figure 6~7 As shown, in the riding process, the wave-like convex portion 142 is round and ellipsoidal (ellipsoidal and flat); the spaced concave portion 143 is recessed from the convex portion 142 inwardly, and becomes thicker and thinner again, so that this The invented tire not only has the comfort of the traditional ring cavity structure, but also has the support strength of the traditional cavity structure...

Embodiment 2

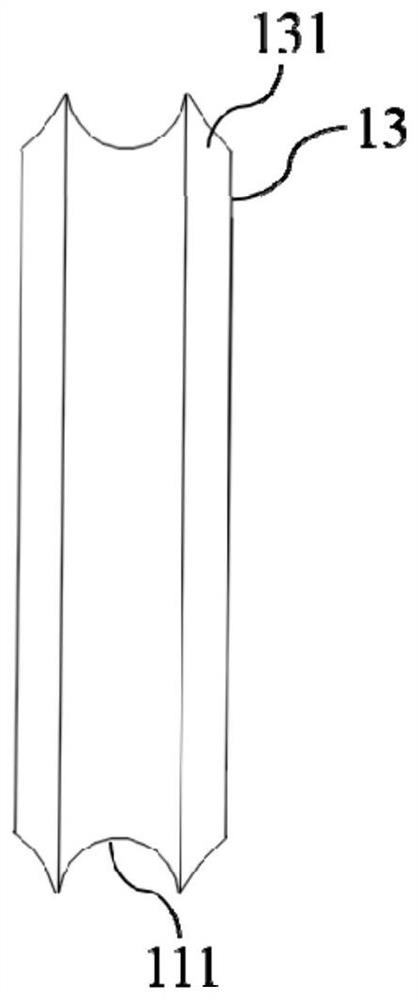

[0041] A kind of cavity extension periodical wave type non-pneumatic tire of this embodiment, the basic structure is the same as embodiment 1, difference and improvement are: as figure 1 , 3 , 6, the crown 11 is provided with a crown groove 111 along its circumference, and the crown groove 111 is filled with material A112, and the material A112 is a high wear-resistant, anti-wet skid tread Rubber material to solve the problem of safety hazards caused by tire jumping or even fracture caused by uneven tire joints in the molding process, and can be eliminated or pre-warned.

[0042] Such as Figure 4 , 6 As shown, it also includes a sidewall part 13, the middle part of the sidewall part 13 is provided with a sidewall part groove 131 along its circumferential direction, and the material B132 is filled in the sidewall part groove 131, and the material B132 is Foaming and other related lightweight cushioning materials, use lightweight cushioning materials for the sidewall 13 that...

Embodiment 3

[0044] A kind of processing method of inner cavity extension periodical wave type non-pneumatic tire of this embodiment, basic structure is the same as embodiment 2, difference and improvement are: as Figure 4-8 shown, including the following steps:

[0045] Step 1. Extruding the tire embryo strip 1: using a screw extruder to extrude the kneaded rubber material into the tire embryo strip 1 provided with a tire belly groove 121 along its circumferential direction on the tire belly 12;

[0046] Step 2. Preforming preparation: cut the extruded tire green strip 1 into segments according to the size, and then wrap it on the mold core member 5 with the help of tooling, so that the mold core member 5 is equidistant along the tire belly 12 Embedded in the belly groove 121, the belly groove 121 can ensure the accurate alignment and insertion of the mold core member 5, and can also play the role of limiting and clamping, so as to ensure the smooth progress of the subsequent molding pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com