Horizontal untwisting machine

A back-twisting machine and horizontal technology, applied in the field of pay-off equipment, can solve the problems of easy springback, affect the quality of finished products, and easy springback of wires, so as to prevent springback, overcome internal stress, and reduce the number of settings. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The application will be described in further detail below in conjunction with the accompanying drawings.

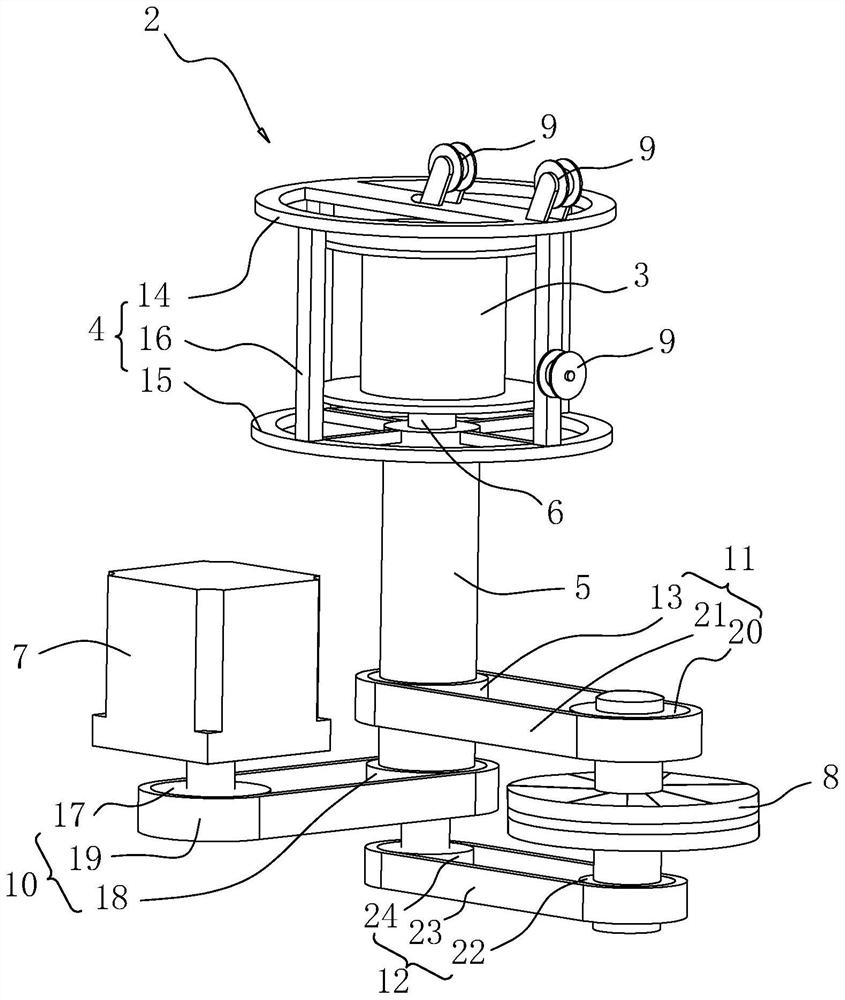

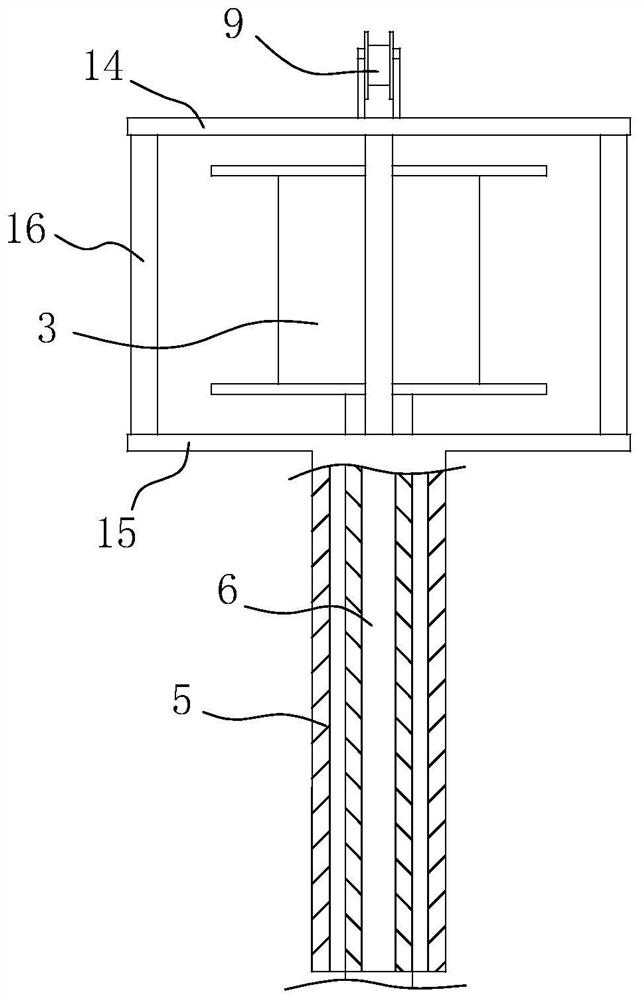

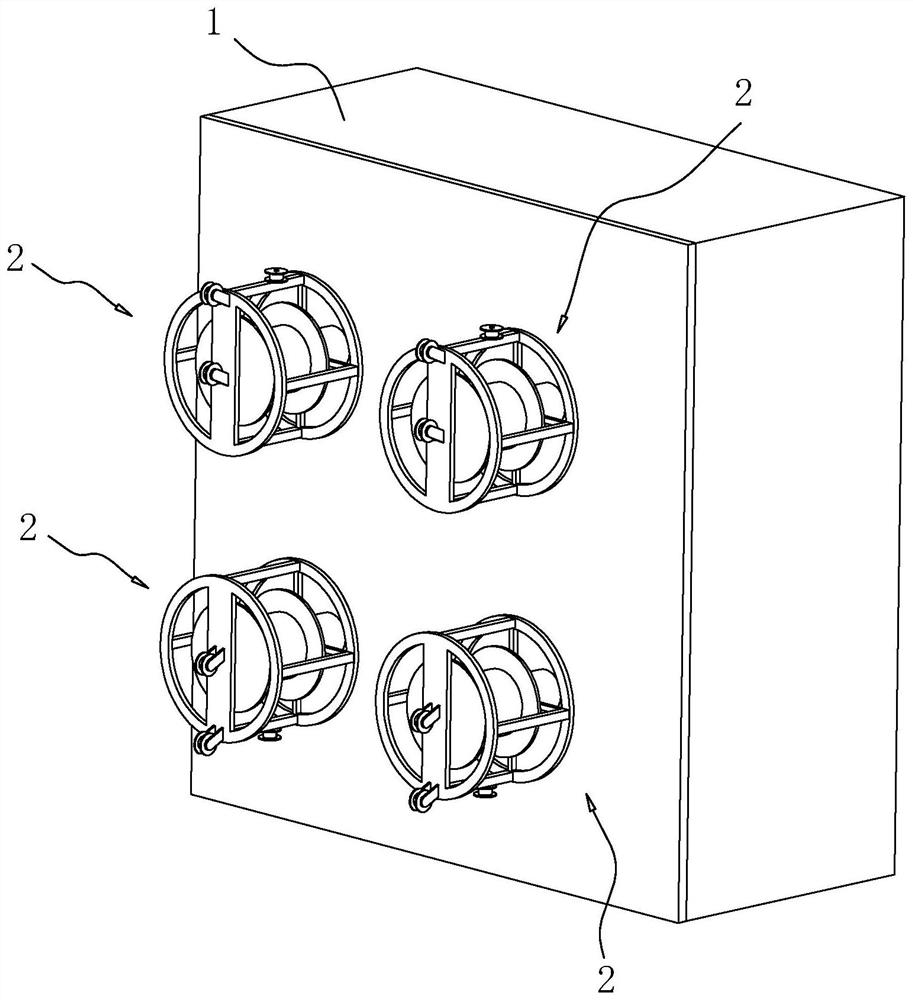

[0032] refer to figure 1 and figure 2 , a horizontal untwisting machine, comprising a body 1, the body 1 is provided with a single wire untwisting assembly 2, and the single wire untwisting assembly 2 includes a wire frame 3, a ship frame 4, a first rotating shaft 5, a second rotating shaft 6, a first driving Part 7, magnetic powder clutch 8, first transmission assembly 10, second transmission assembly 11, and third transmission assembly 12; wire frame 3 and ship frame 4 are all arranged horizontally, and wire frame 3 is accommodated in ship frame 4, The first rotating shaft 5 is hollowly arranged, and the inner diameter of the first rotating shaft 5 is greater than the diameter of the second rotating shaft 6, and the second rotating shaft 6 runs through the first rotating shaft 5; The other end of the first rotating shaft 5 is connected to the first driving mem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com