Mechanical equipment for producing polypropylene fibers

A polypropylene fiber and mechanical equipment technology is applied in the field of machinery and equipment for producing polypropylene fibers, which can solve the problems of difficult removal of cutting knives, reduce the cleanliness of polypropylene fibers, etc., and achieve the effect of ensuring cleanliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] as attached figure 1 to attach Figure 4 Shown:

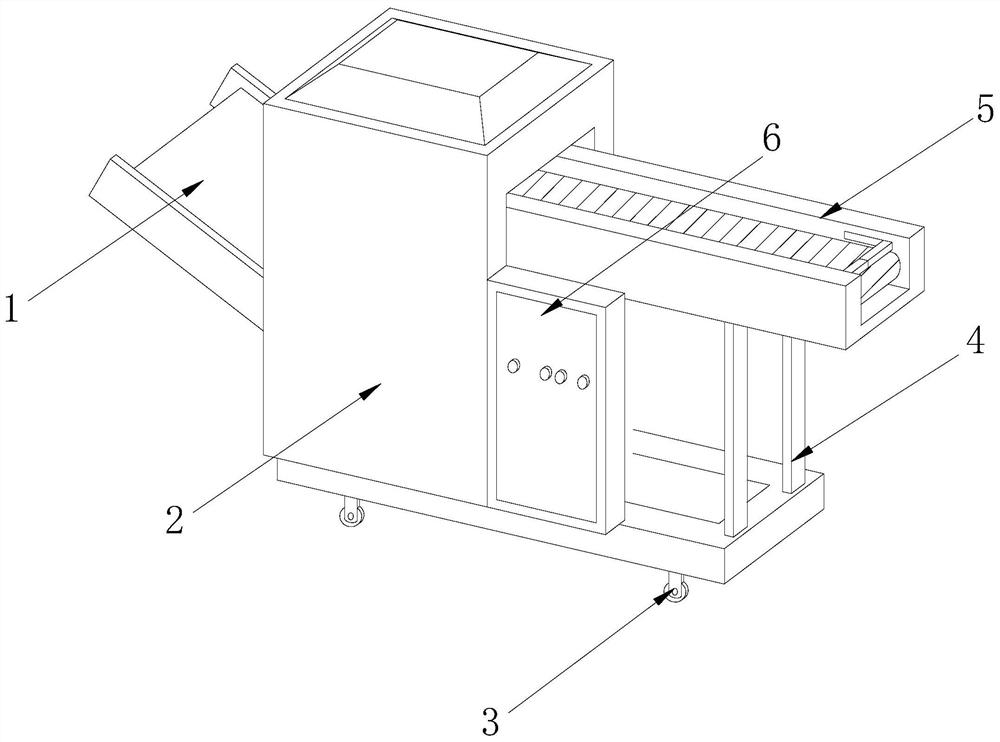

[0025] The present invention provides a kind of mechanical equipment for producing polypropylene fiber. Its structure includes: feeding port 1, body 2, universal wheel 3, bracket 4, conveying device 5, electric box 6, the right side of the feeding port 1 side and the left side of the fuselage 2 are electrically welded, the middle of the universal wheel 3 is movably engaged under the bracket 4, the left side of the conveying device 5 is nested inside the fuselage 2, and the electric box The left side bolt of 6 is connected to the right side of fuselage 2.

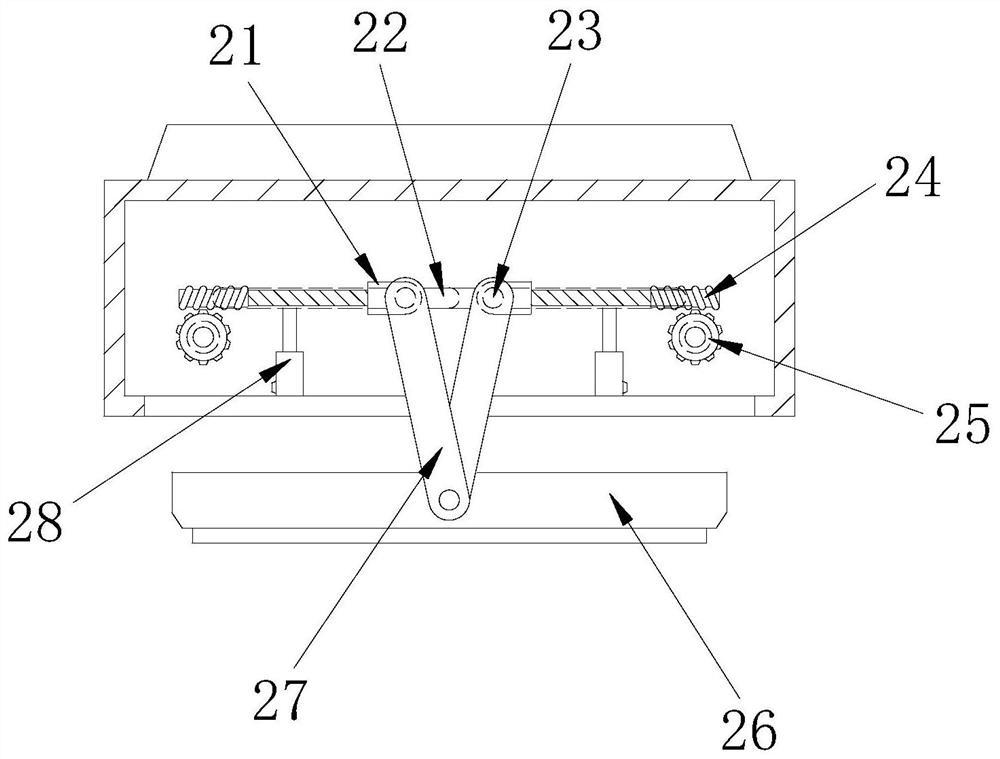

[0026] Described fuselage 2 comprises sleeve 21, moving slot 22, slide block 23, worm screw 24, No. 1 gear 25, cutter 26, moving rod 27, telescoping rod 28, and the both sides of described sleeve 21 and worm screw 24 carry out Fixedly connected, the moving slot 22 and the fuselage 2 are an integrated structure, the slider 23 is nested inside the sleeve 21, the two ...

Embodiment 2

[0032] as attached Figure 5 to attach Figure 7 Shown:

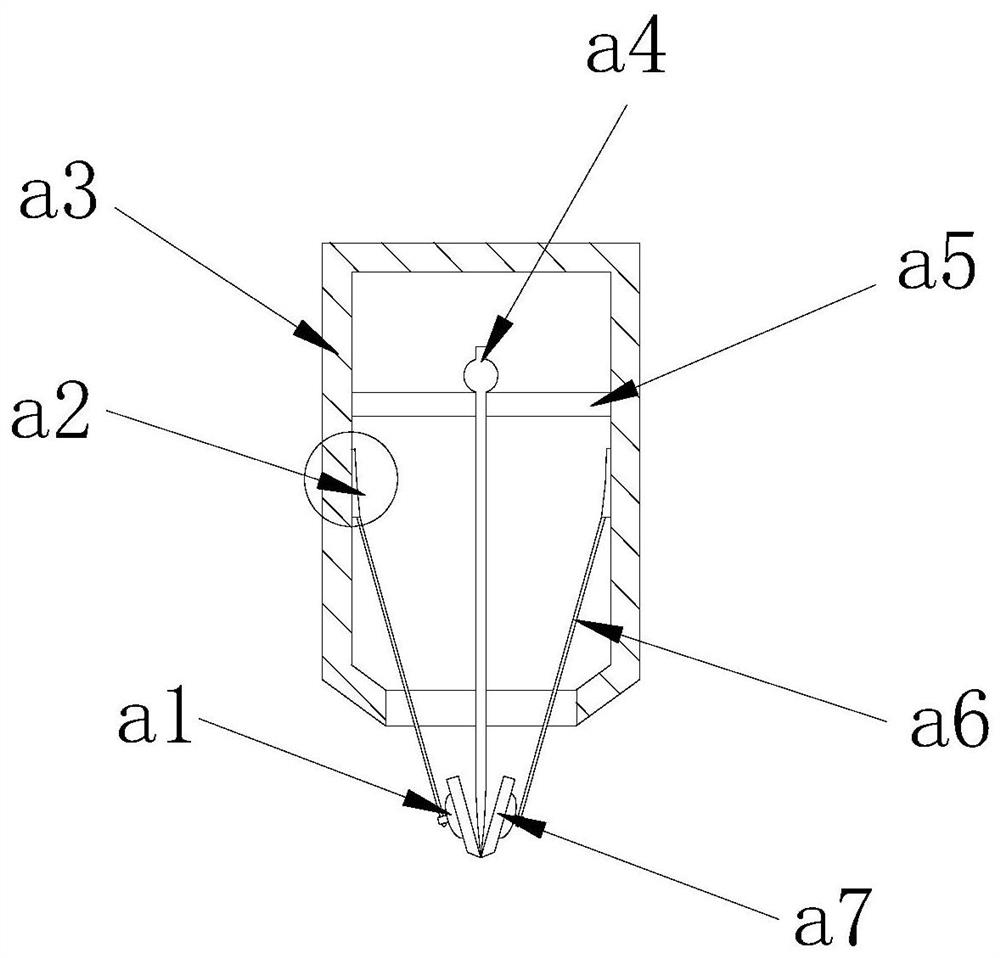

[0033]The present invention provides a kind of mechanical equipment for producing polypropylene fiber. The conveying device 5 includes an air bag 51, a conveyor belt 52, a fixed block 53, a positioning plate 54, and a rotating device 55. The air bag 51 is bonded to the concave surface of the fixed block 53. The conveyor belt 52 is installed in the middle of the positioning plate 54 through movable engagement, the two sides of the fixed block 53 are bolted to the inner side of the positioning plate 54, and the two ends of the rotating device 55 are movably engaged in the middle of the positioning plate 54 , the airbag 51 is made of rubber material, which can buffer the baffle c1.

[0034] Wherein, the rotating device 55 includes a baffle c1, a second gear c2, a rack c3, and a straight shaft c4, the baffle c1 is fixedly connected to the second gear c2 through the straight shaft c4, and the second gear c2 passes through ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap