Self-adaptive embedded channel of cylindrical surface in railway contact network tunnel

A technology of pre-buried channels and tunnels, which is applied in mining equipment, mining equipment, earthwork drilling and mining, etc. It can solve the problems of large amount of anchor reinforcement, complex tooth groove processing, and application of materials with poor mechanical properties, so as to achieve enhanced bearing capacity Fatigue load capability, elimination of stress concentration, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. It should be noted here that the descriptions of these embodiments are used to help understand the present invention, but are not intended to limit the present invention. In addition, the technical features involved in the various embodiments of the present invention described below may be combined with each other as long as they do not constitute a conflict with each other.

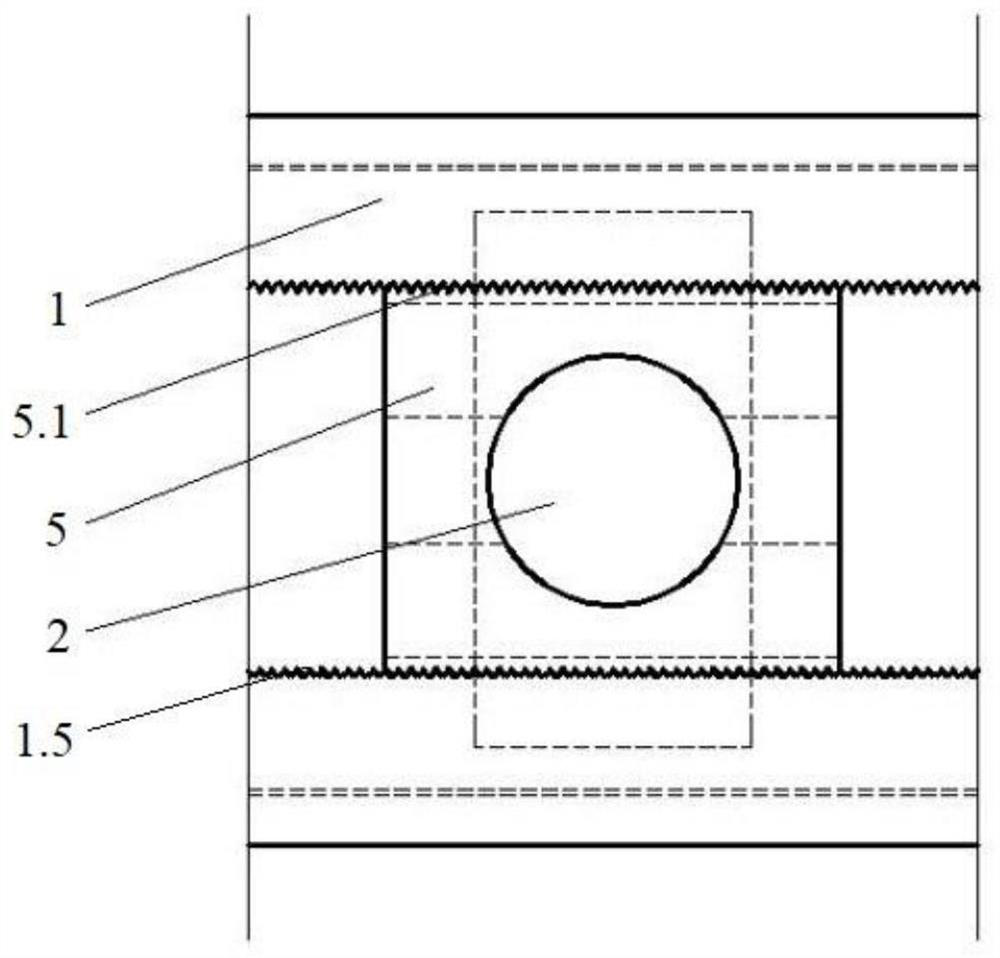

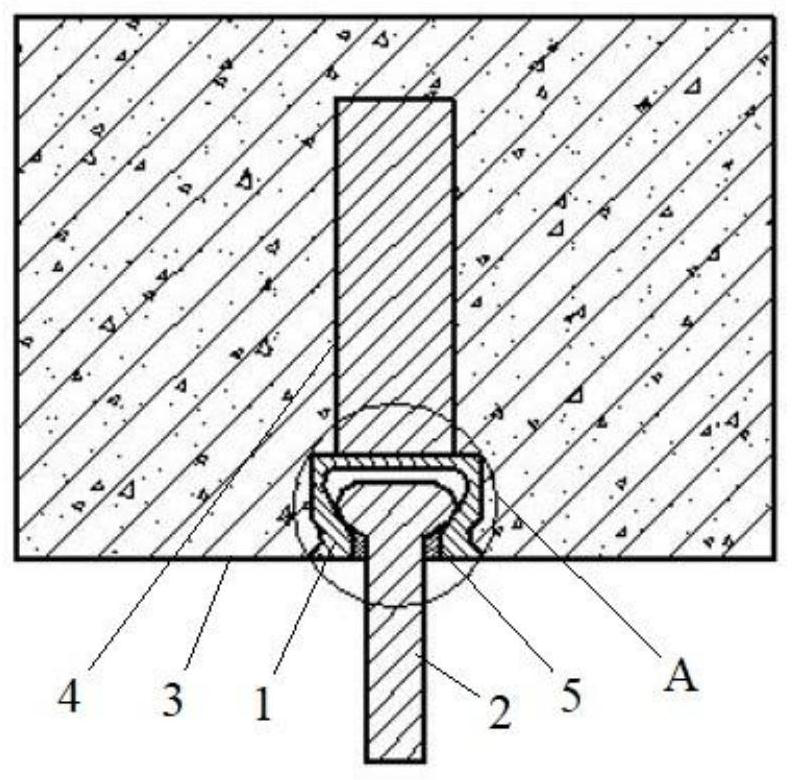

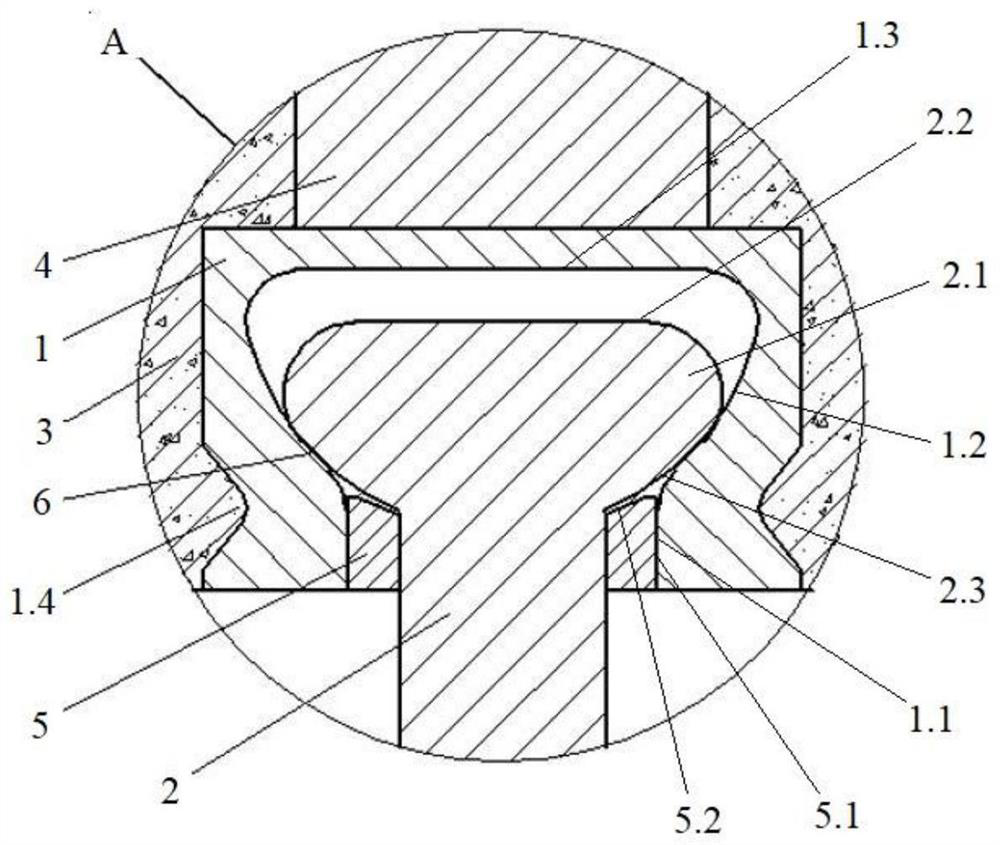

[0023] Such as Figure 1-4 As shown, the present invention provides a cylindrical self-adaptive pre-buried channel in a railway catenary tunnel, including a special-shaped steel channel 1 embedded in the inner wall 3 of the tunnel along the longitudinal direction of the line and installed in the special-shaped steel channel at intervals along the longitudinal direction of the line The heart-shaped bolt 2, the special-shaped steel channel 1 is fixed on the inner wall of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com