Method for designing, manufacturing and assembling hydrodynamic machines

A technology of hydraulic machines and hydraulic cylinders, which is applied in the field of design, manufacture, and assembly of hydraulic machines, and can solve problems such as environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

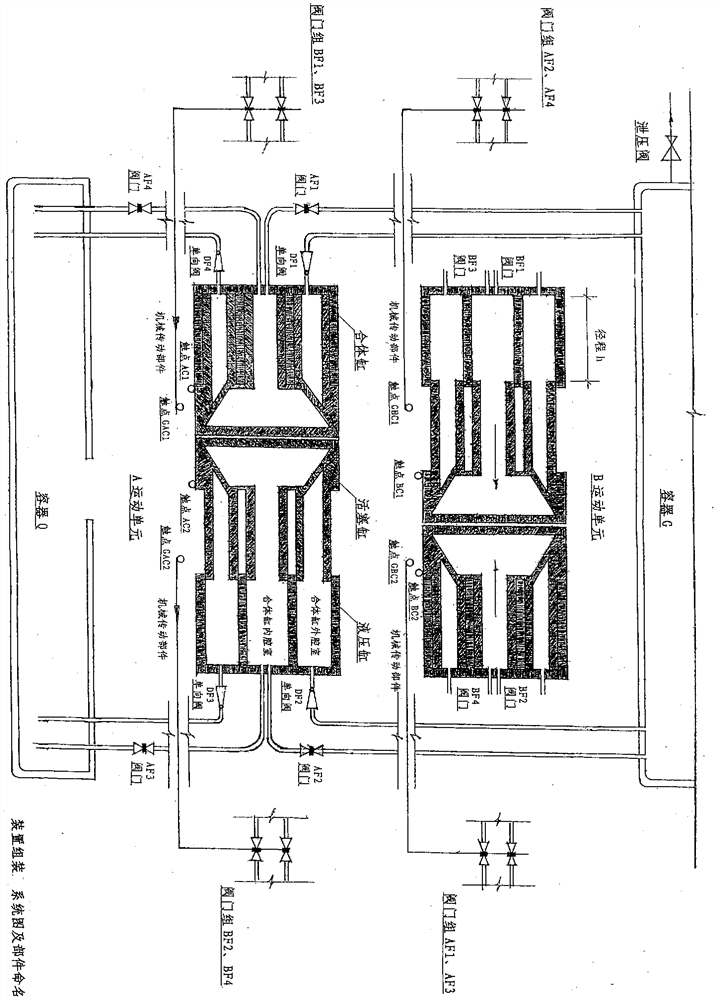

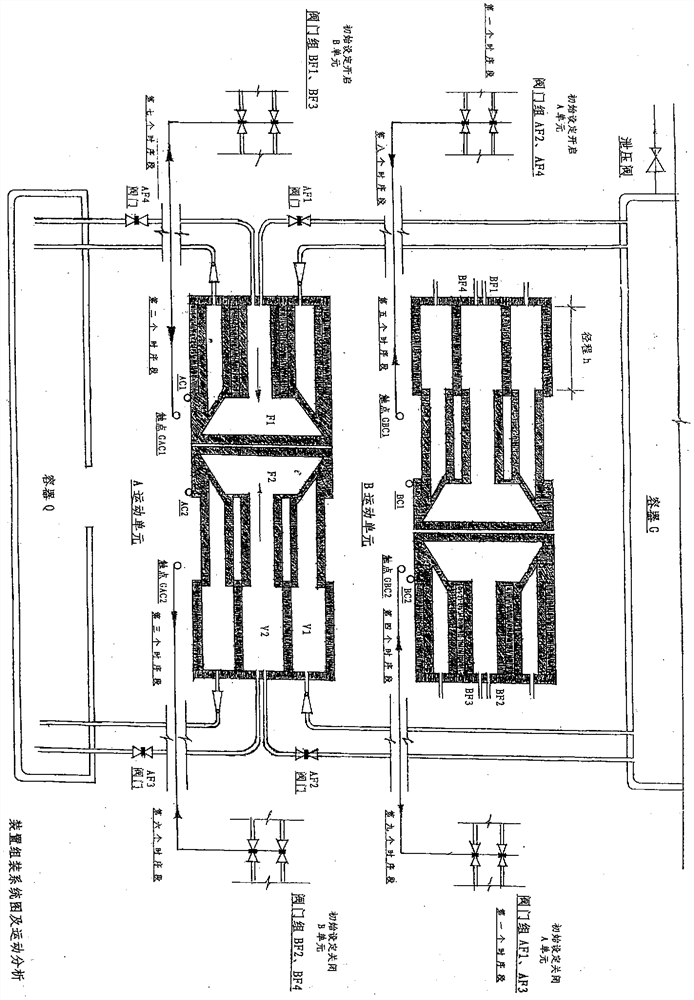

[0063] Such as image 3 As shown, place container G at a high place, container Q at a low place, and fix A and B motion units at appropriate positions; arrange the pipelines of A and B motion units as needed, so that the valves of the pipelines can be arranged in groups , so that it can be connected with the transmission parts and fixed in a suitable position.

[0064] Such as image 3 As shown, the pipeline connection and valve settings of B motion unit are exactly the same as those of A motion unit, so the drawing is omitted.

[0065] Such as image 3 As shown, the pipeline valves of the A and B motion units in the device are arranged in groups, and the valve groups are set as follows: ①AF1, AF3, ②AF2, AF4, ③BF1, BF3, ④BF2, BF4 are coaxial stud valves, and the stud rotates once It can control a group of two valves to open or close at the same time.

[0066] Such as image 3 As shown, the four groups of coaxial stud valve groups are respectively connected to the four lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com