Extensibility tension testing device for electric power fitting

A tensile test and power fitting technology, applied in the field of extensional tensile testing devices, can solve the problems of inaccurate test results, numerous influencing factors, position displacement, etc., to achieve good safety and reliability, scientific and reasonable structure, and safe and convenient use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

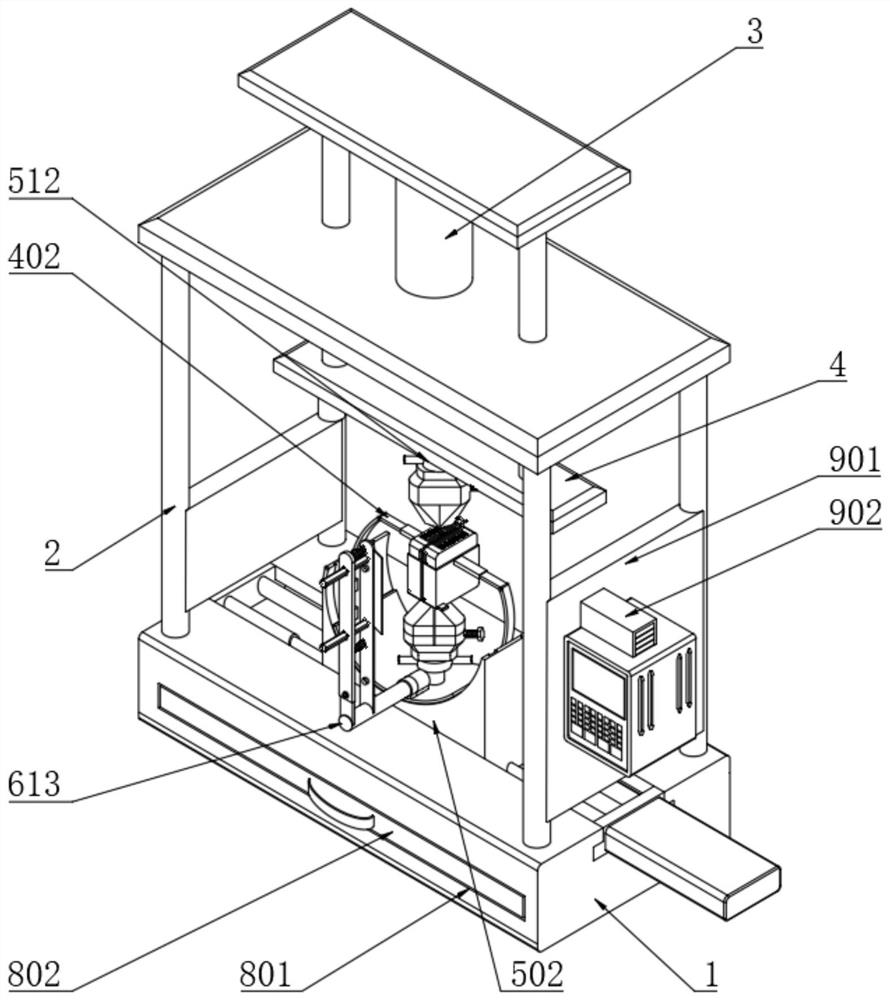

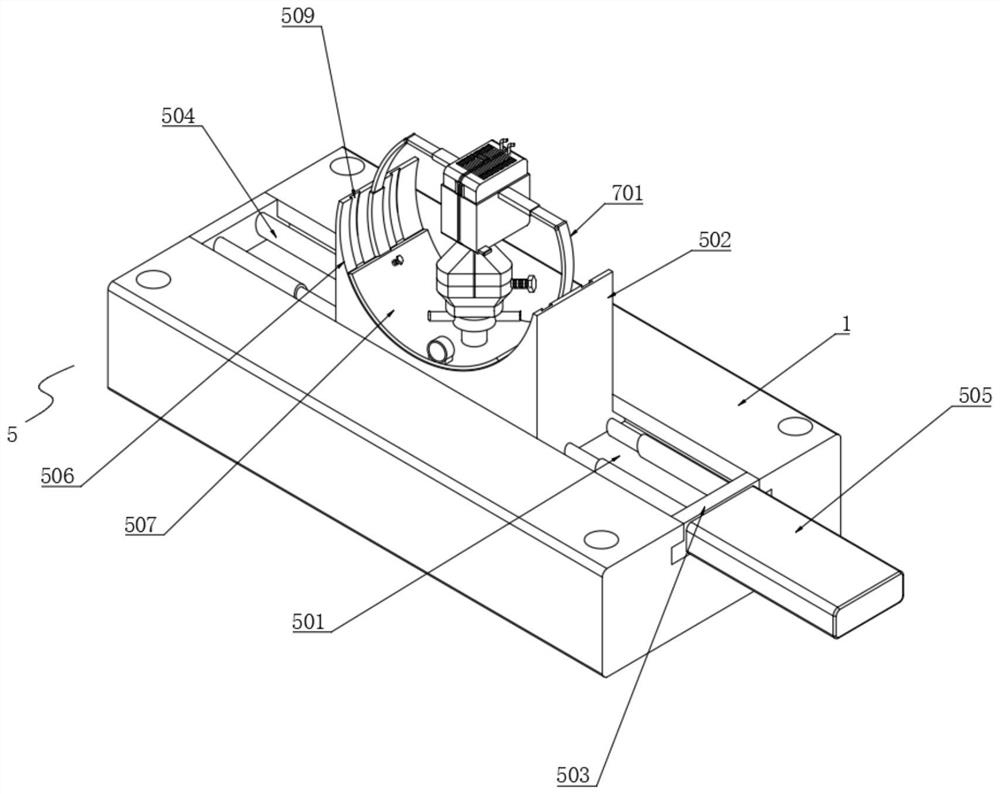

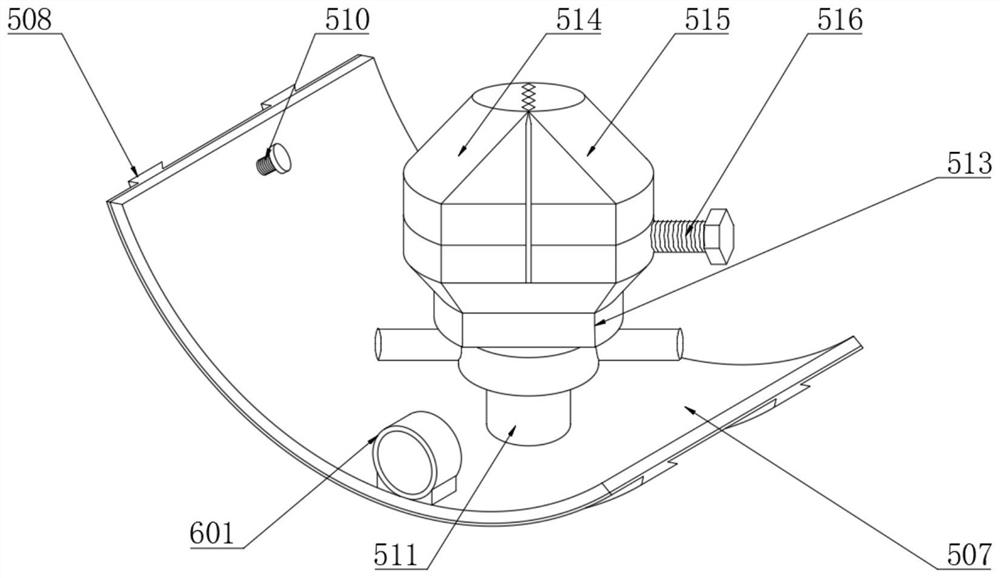

[0047] Example: such as Figure 1-9 As shown, the present invention provides a technical scheme of an extensibility tensile testing device for electric fittings, including a base 1, a support frame 2 is installed in the middle of the top surface of the base 1, a vertical hydraulic cylinder 3 is installed on the top of the support frame 2, and the vertical hydraulic cylinder 3 pushes The rod end is connected with a movable frame 4, the movable frame 4 runs through the top of the support frame 2, the top of the base 1 is equipped with a multi-angle detection assembly 5, and the multi-angle detection assembly 5 includes an adjustment groove 501, a test seat 502, a mounting plate 503, a telescopic rod 504, Horizontal hydraulic cylinder 505, semi-circular groove 506, bearing plate 507, arc-shaped sliding bar 508, arc-shaped chute 509, positioning screw 510, bottom fixture seat 511, top fixture seat 512, bracket 513, fixed clip 514, movable clip 515 , Adjusting screw rod 516, clampi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com