Digital design method for feed induction feedback loop of electronic instrument

A feedback loop, electronic instrument technology, applied in the direction of electric controllers, controllers with specific characteristics, etc., can solve the problems of Gibbs overshoot, limited transmission bandwidth, undershoot, etc., to avoid ringing, improve safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

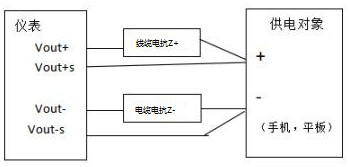

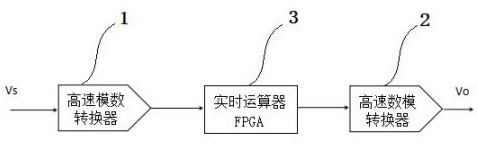

[0057] see figure 1 As shown, a digital design method of an electronic instrument feed induction feedback loop includes designing a digital feedback loop composed of a high-speed analog-to-digital converter 1, a high-speed digital-to-analog converter 2, and a digital operator 3 that meet the maximum system response time constraints , and design the feedback algorithm running on the digital operator 3 to replace the traditional analog linear generation or nonlinear feedback circuit, so as to realize the real-time adjustment of the feed terminal voltage to compensate the feed cable according to the reverse direction of the signal amplitude of the induction terminal Loss, so that the signal amplitude applied by the instrument to the target end reaches the set value, while avoiding the risk of Gibbs ringing phenomenon; among them,

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com