Disassembly and assembly robot for primary side high-water-level blocking plate of nuclear power station steam generator

A steam generator, high water level technology, applied in the direction of manipulator, program control manipulator, metal processing, etc., can solve the problem of large exposure dose and achieve the effect of small space interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In describing the present invention, it should be understood that the terms "left end", "right end", "above", "below", "outside", "inside", "upper end", "lower end" etc. indicate orientation or position The relationship is based on the orientation or positional relationship shown in the drawings, and is only for the convenience of describing the present invention and simplifying the description, rather than indicating or implying that the referred device or element must have a specific orientation, be constructed and operated in a specific orientation, therefore It should not be construed as a limitation of the present invention.

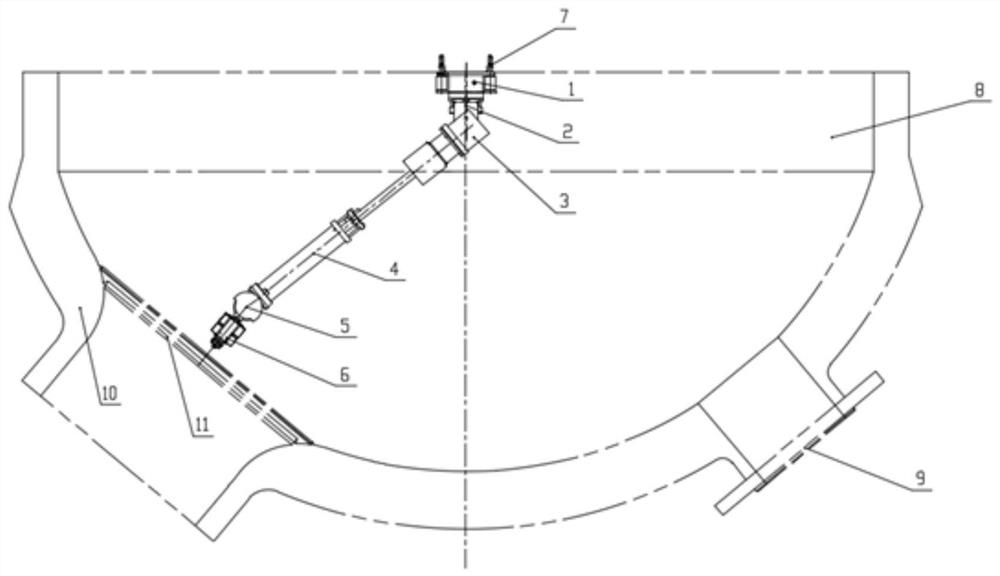

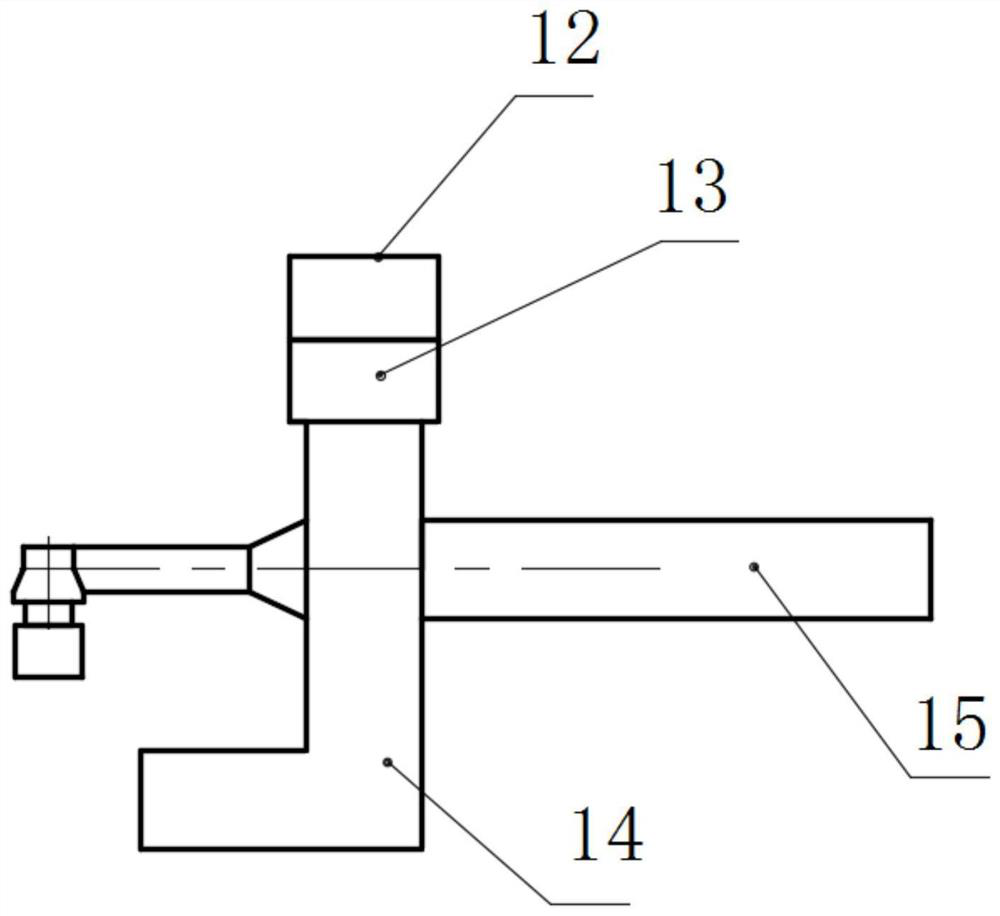

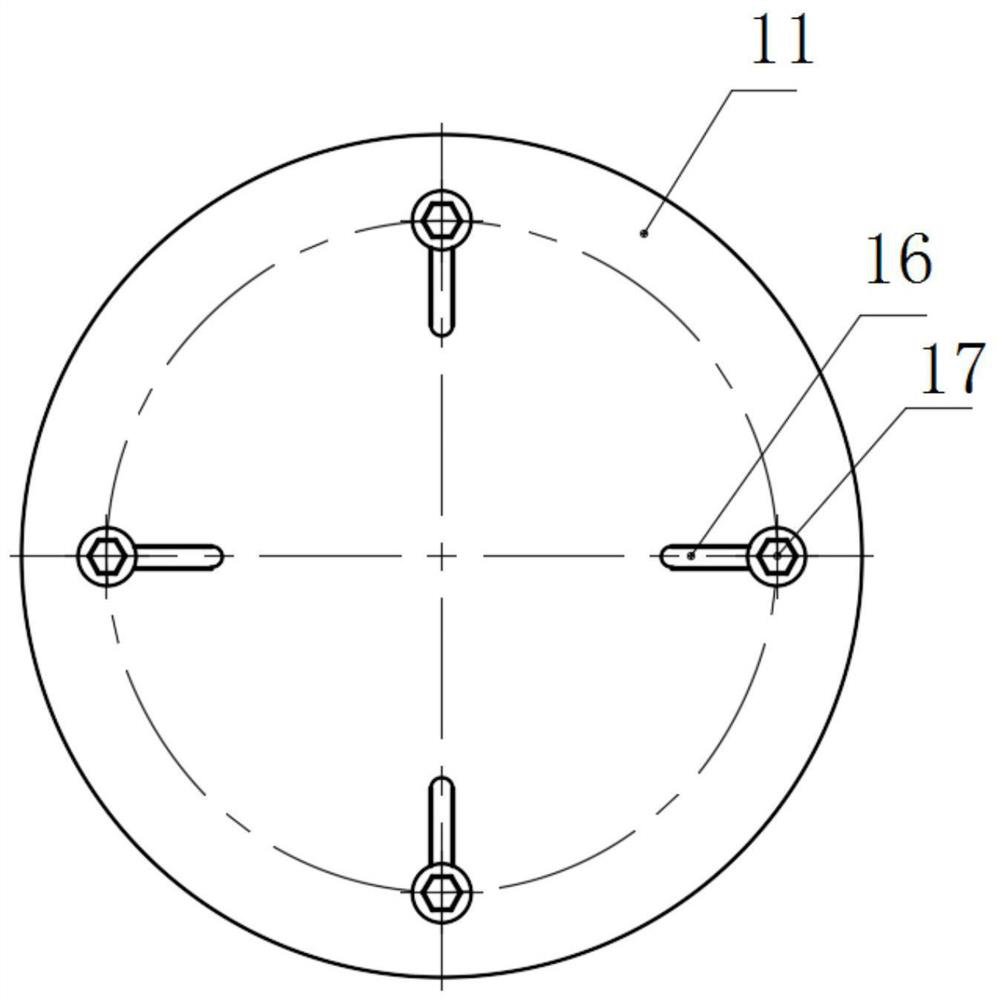

[0029] The present invention provides a robot for removing and assembling the high water level blocking plate on the primary side of a steam generator in a nuclear power plant, which includes a six-axis series joint, and the six-axis series joint includes a first joint 1, a second joint 2, a third joint 3, The fourth joint 4 , the fifth joint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com