Method for determining optimal pressure maintaining parameters in injection molding process

A definite method and the best technology, applied in the field of injection molding process parameter setting, can solve the problems of unstable plastic products and the inability to determine the best pressure-holding parameters of the injection molding process, so as to avoid the time and cost of machine adjustment and avoid continuous deformation of products Effects of fluctuations, time savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

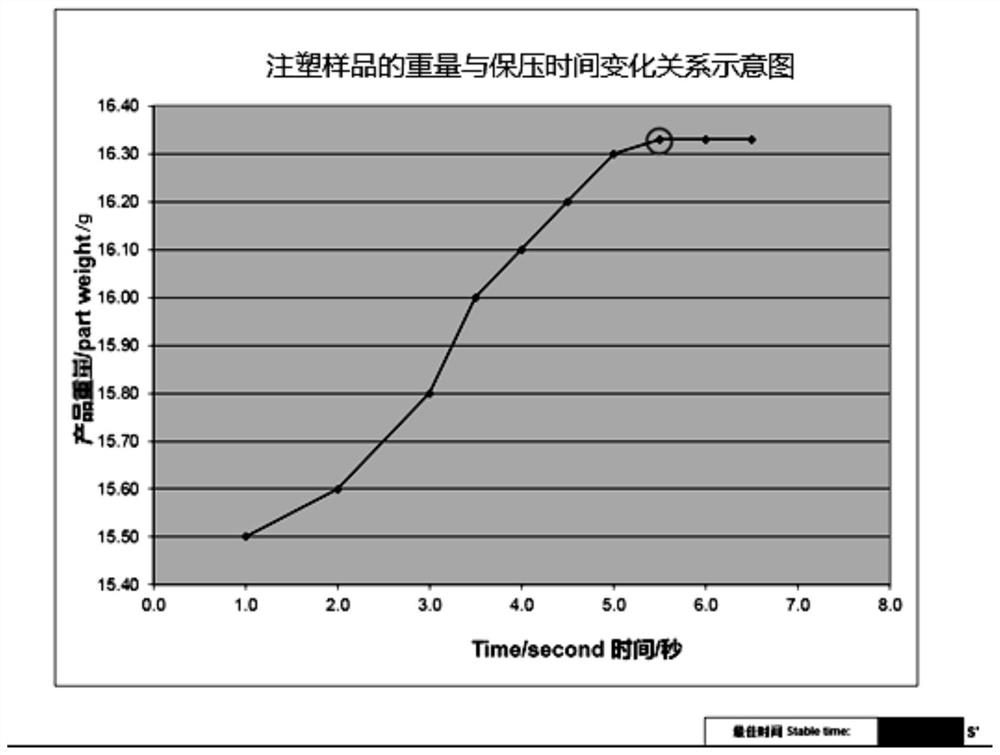

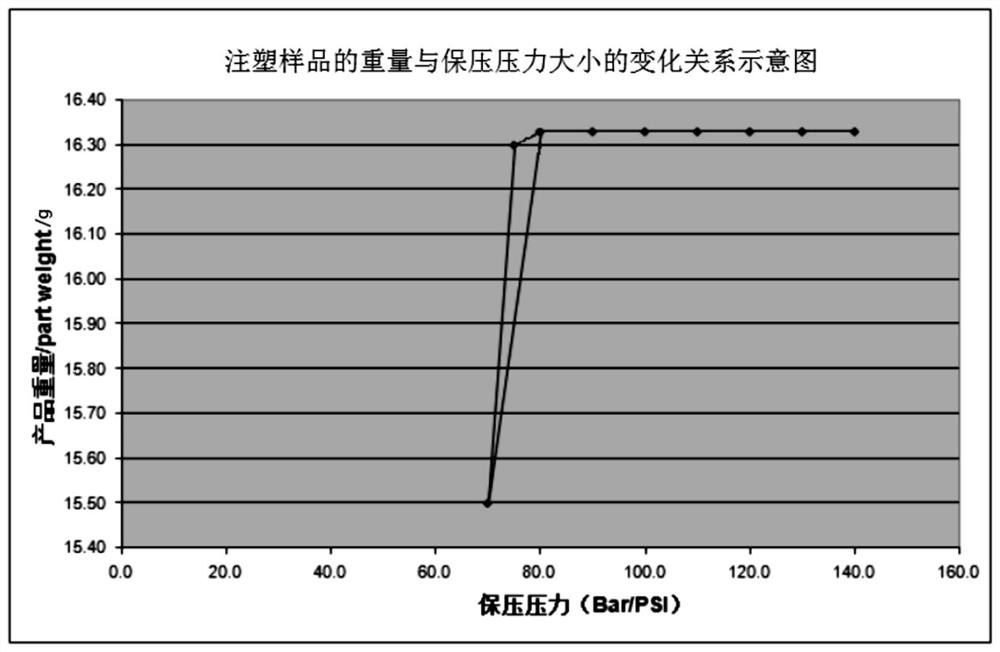

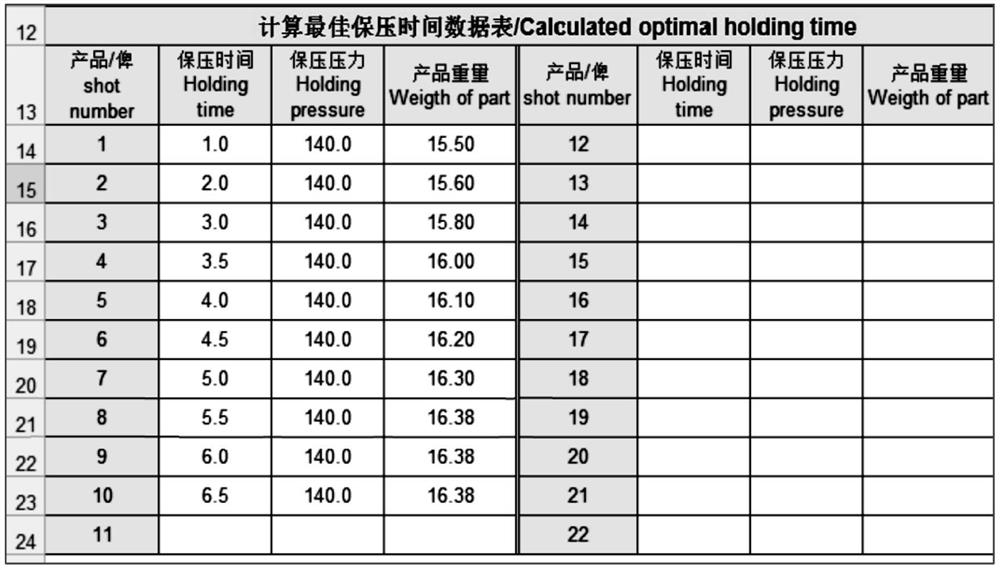

[0017] The present invention proposes a method for determining optimal pressure-holding parameters in an injection molding process, wherein the optimal pressure-holding parameters include: optimal pressure-holding position, optimal pressure-holding time and optimal pressure-holding pressure. The method includes the following steps:

[0018] S100, determining an optimal pressure holding position. When adjusting the injection molding machine, set the best holding pressure position when the injection product is injected to 95%-99%. For example, set the best holding pressure position to the position where the injection product is injected to 99%. If the holding pressure position is set too far ahead, the product will turn to holding pressure before it is filled to the best holding pressure position, and the injection molded product will have defects such as lack of glue, small size, shrinkage, deformation, etc.; if the holding pressure position is set Too far back, that is, the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com