Vehicle roller blind device having roller blind web

A technology for roller blinds and vehicles, applied in the field of equipment implementing this method, the edge strips of roller blinds, can solve problems such as reducing the strength and durability of bonding connections, damage, and failure to reliably meet bonding durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

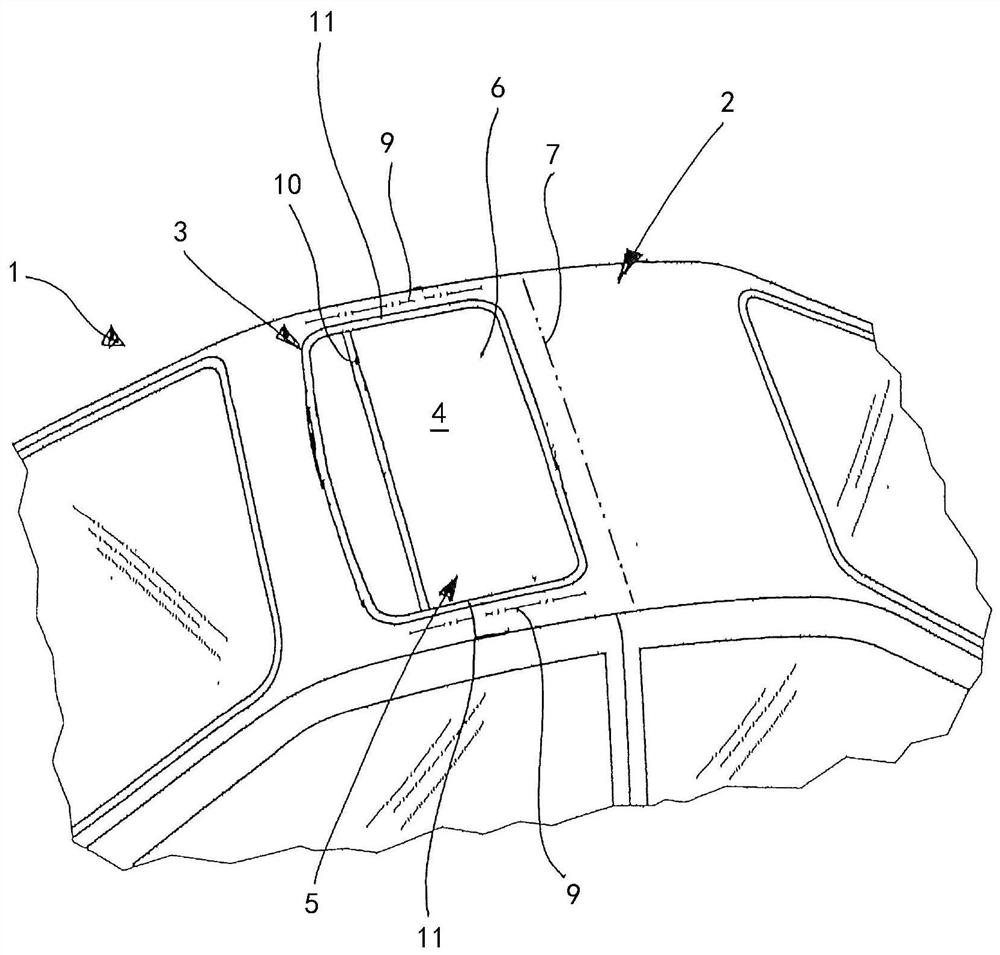

[0040] A vehicle 1, such as a passenger car, has a roof 2 with a transparent roof region, which is arranged, for example, in a roof opening 3 (see figure 1 ) The cover 4 is formed. The cover 4 is especially a glass cover or a plastic cover. However, the cover 4 can also be fixedly mounted on the vehicle roof. Furthermore, the transparent roof region can also be a roof module or a roof section of a glass roof or the like.

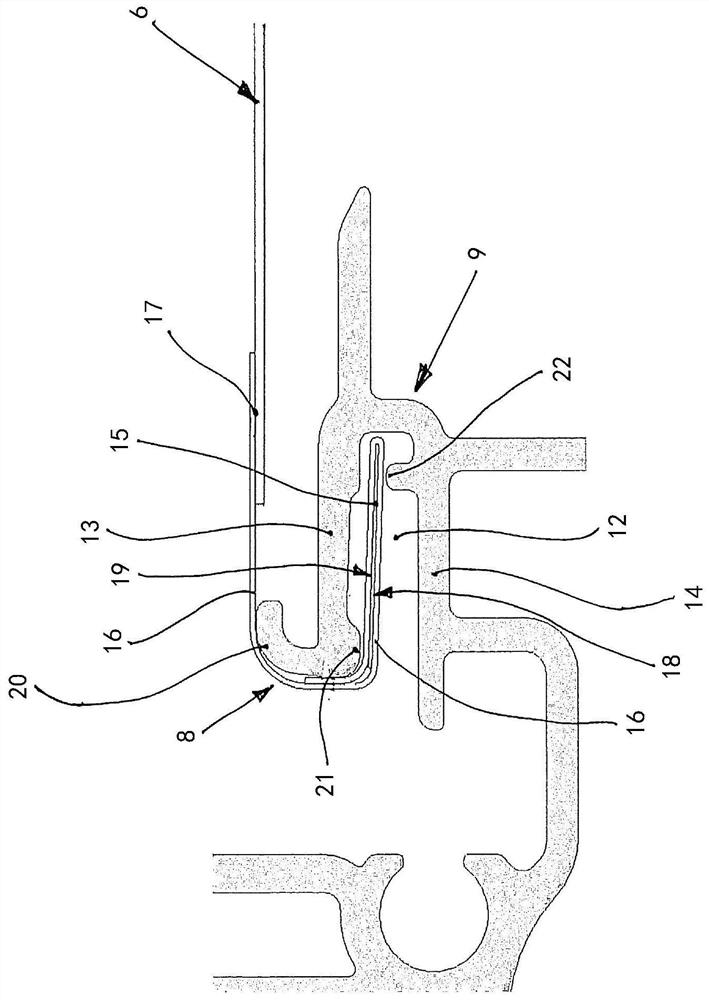

[0041] A vehicle roller blind arrangement 5 is arranged below the vehicle roof 2 in order to shade the transparent roof area. The roller blind web 6 of the vehicle roller blind arrangement 5 , which can be wound onto a reel 7 and which can be unrolled therefrom, is guided with its respective side edge 8 on guide rails 9 which are arranged in the transparent top region or cover 4 On both sides and along the direction of movement of the roller blind web 6 . The guide rails 9 are assigned exclusively to the vehicle roller blind arrangement 5 and are designe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com