Self-driven logistics trolley rotating box

A trolley and box technology, used in conveyors, packaging, mechanical conveyors, etc., can solve problems such as breaking the box cover, and achieve the effect of easy operation and reducing safety accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

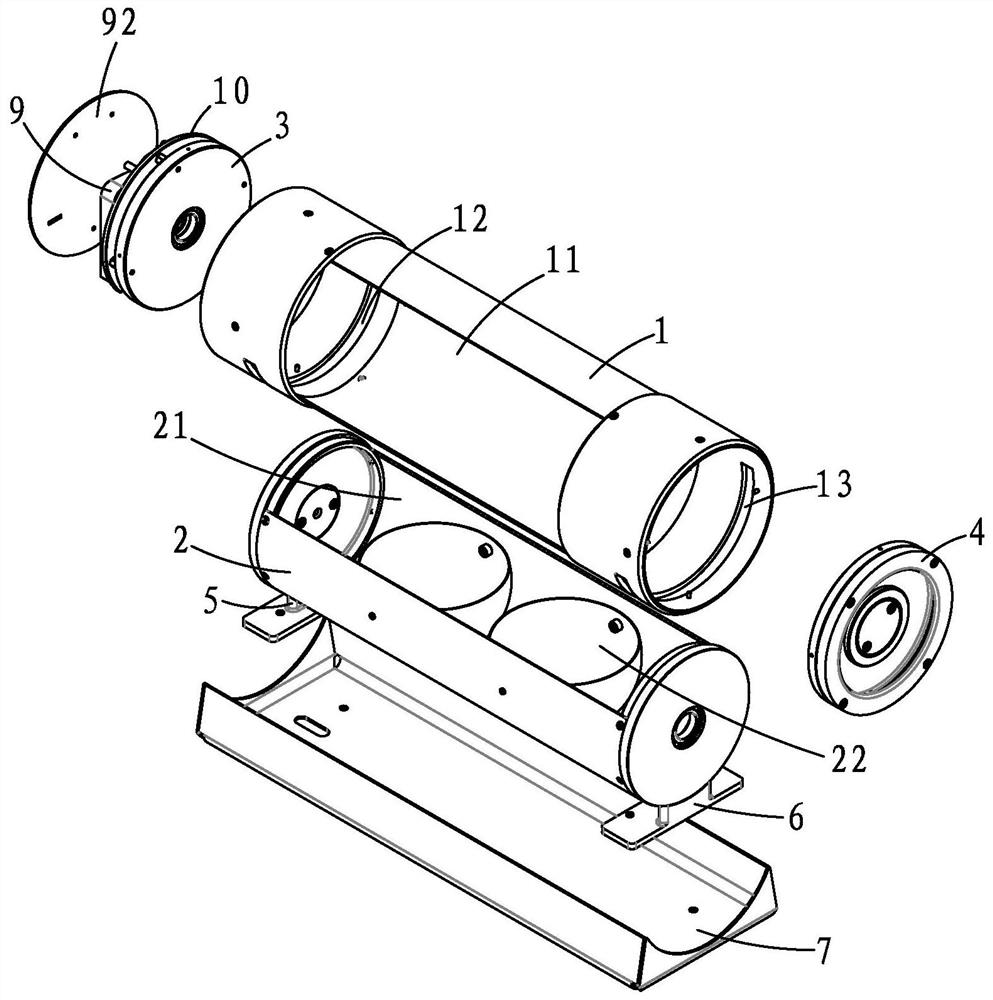

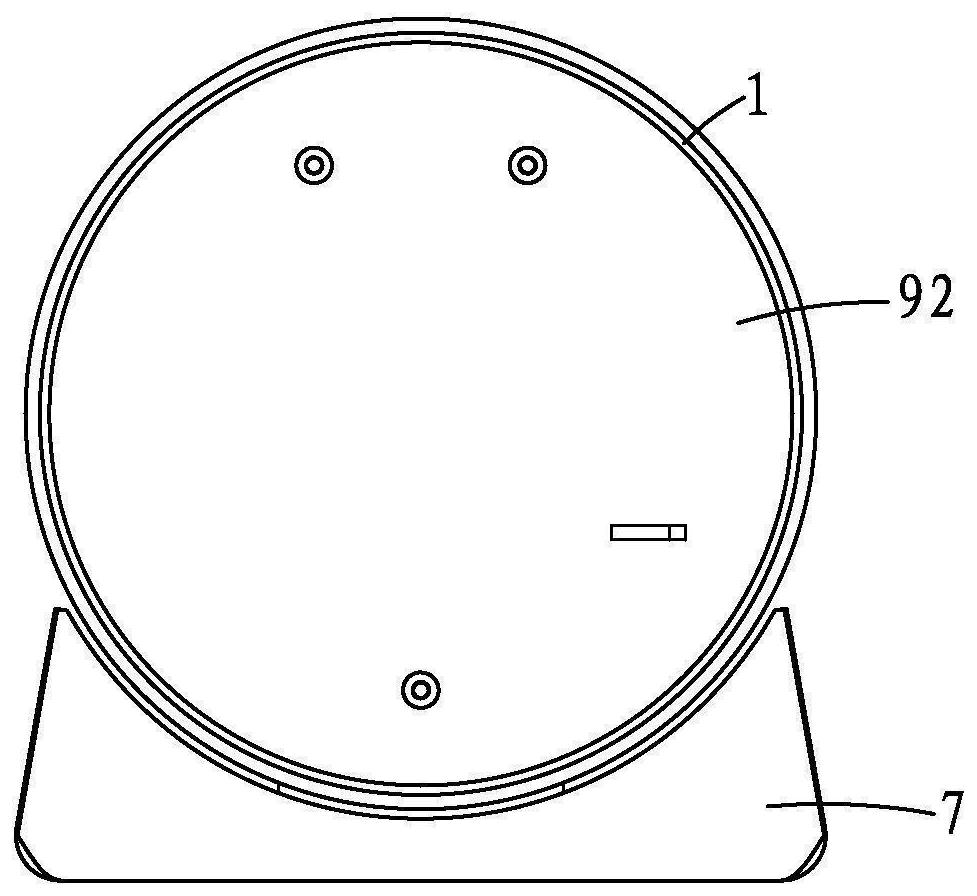

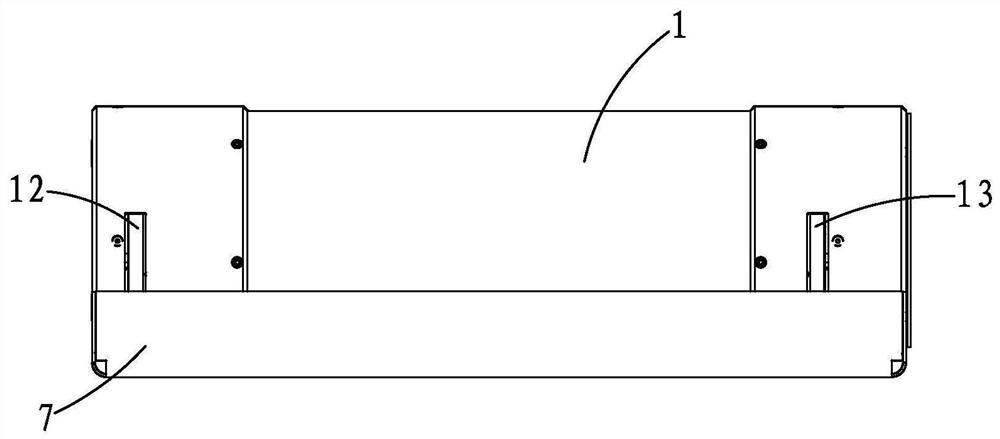

[0027] The embodiment of the present invention solves the technical problem in the prior art of how to avoid items in the box from breaking the box cover by providing a self-propelled logistics trolley rotating the box body, and realizes the technical effect of realizing the rotary switch box body.

[0028] The technical solution in the embodiment of the present invention is to solve the above-mentioned problems, and the general idea is as follows: the outer shell and the inner shell form a box, and as the inner and outer shells rotate at different angles, the first access port and the second access port Switch between communicating and blocking states. When the first access opening communicates with the second access opening, items can be put into the inner casing or taken out from the inner casing. When the first access opening is connected to the second access opening When the access opening is blocked, the items in the box will not run out of the box.

[0029] In order to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com