A feeding control system, feeding control method and feeding machine

A feeding control system and feeder technology, which are applied to manufacturing tools, feeding of melting furnaces, glass manufacturing equipment, etc., can solve the problems of small discharge volume, large fluctuation of feeding volume, and difficulty in ensuring long-term stable operation of the feeder, etc. Achieving the effect of balancing the liquid level and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementations of the embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It should be understood that the specific implementation manners described herein are only used to illustrate and explain the embodiments of the present invention, and are not used to limit the embodiments of the present invention.

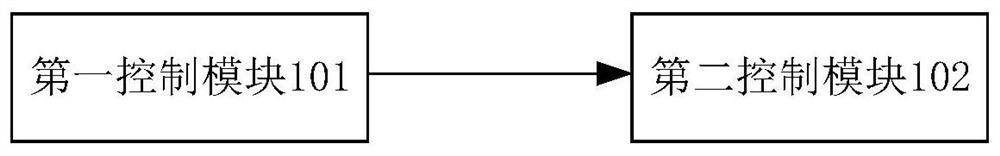

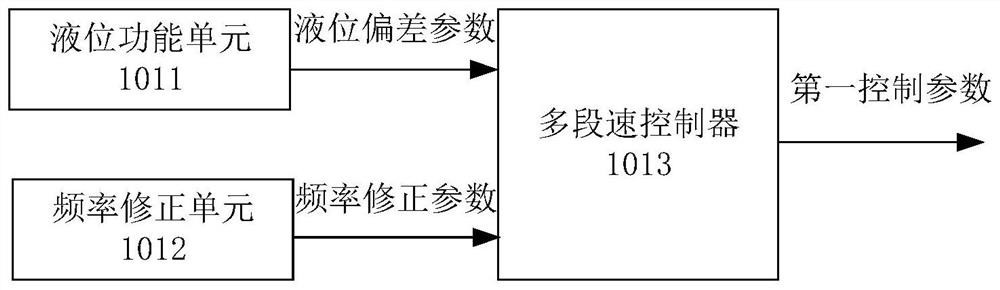

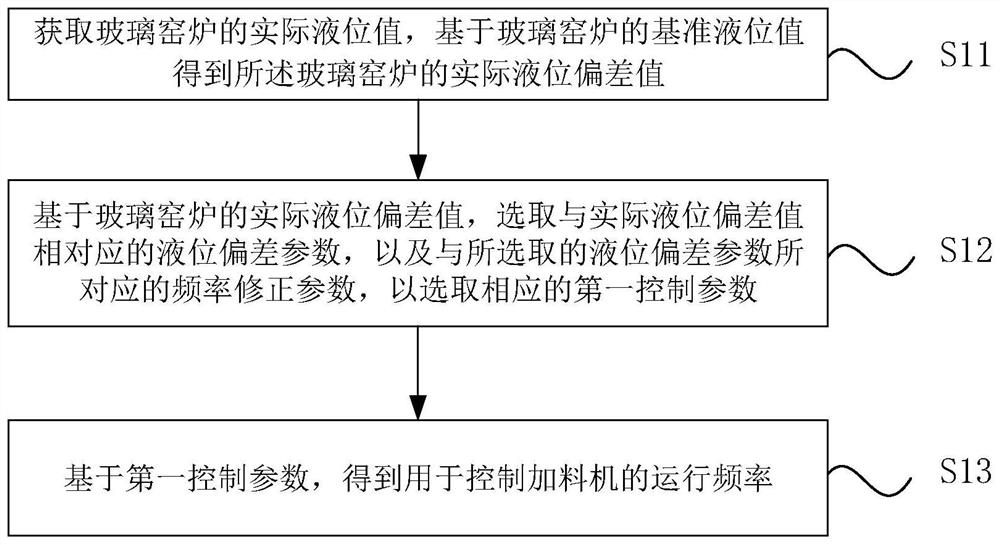

[0023] figure 1 is a feeding control system shown according to an exemplary embodiment, such as figure 1 As shown, the charging control system is applied to a charging machine of a glass furnace, and includes a first control module 101 and a second control module 102 . The first control module 101 is configured to generate a first control parameter group according to the liquid level deviation information of the glass furnace and the frequency correction information of the feeder, wherein the first control parameter group includes a plurality of first control parameters; the second control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com