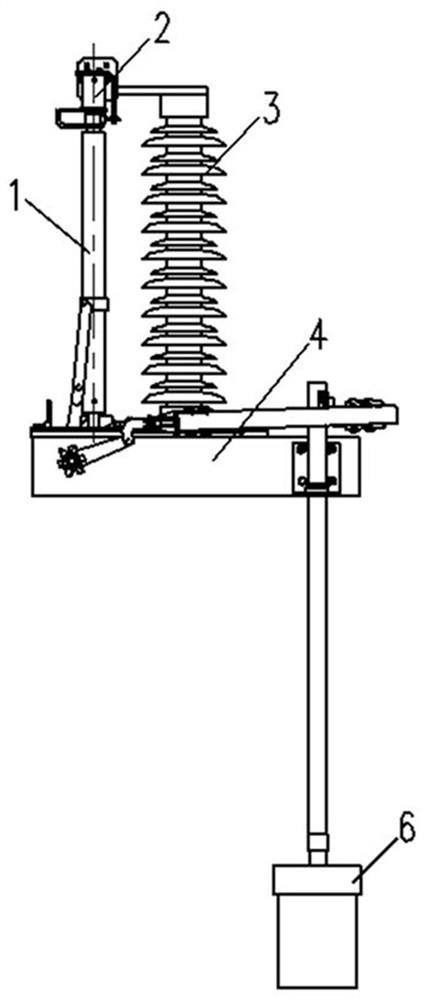

Grounding switch static contact and straight swing plug-in grounding switch

A technology of grounding switch and static contact, which is applied in the direction of grounding switch, electric switch, air switch parts, etc., which can solve the problems of difficult design and manufacture, limited obstruction, etc., to ensure service life, reduce extra wear, and facilitate installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

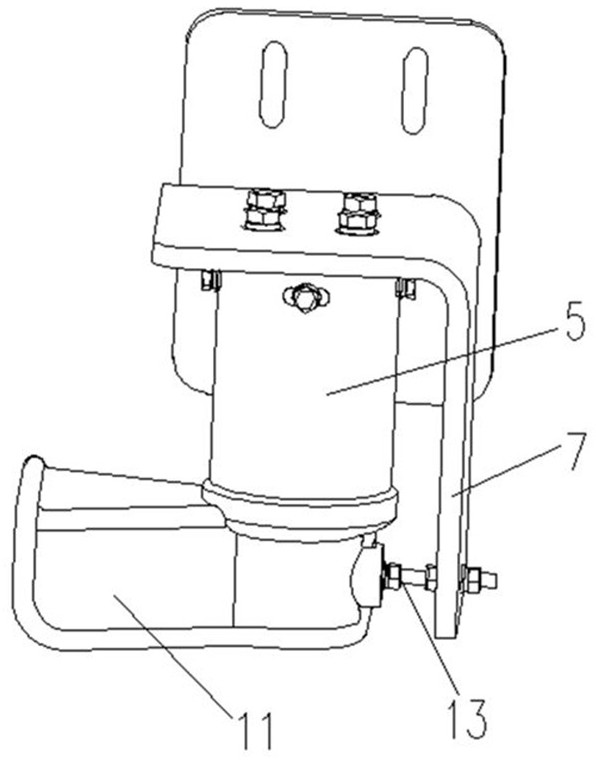

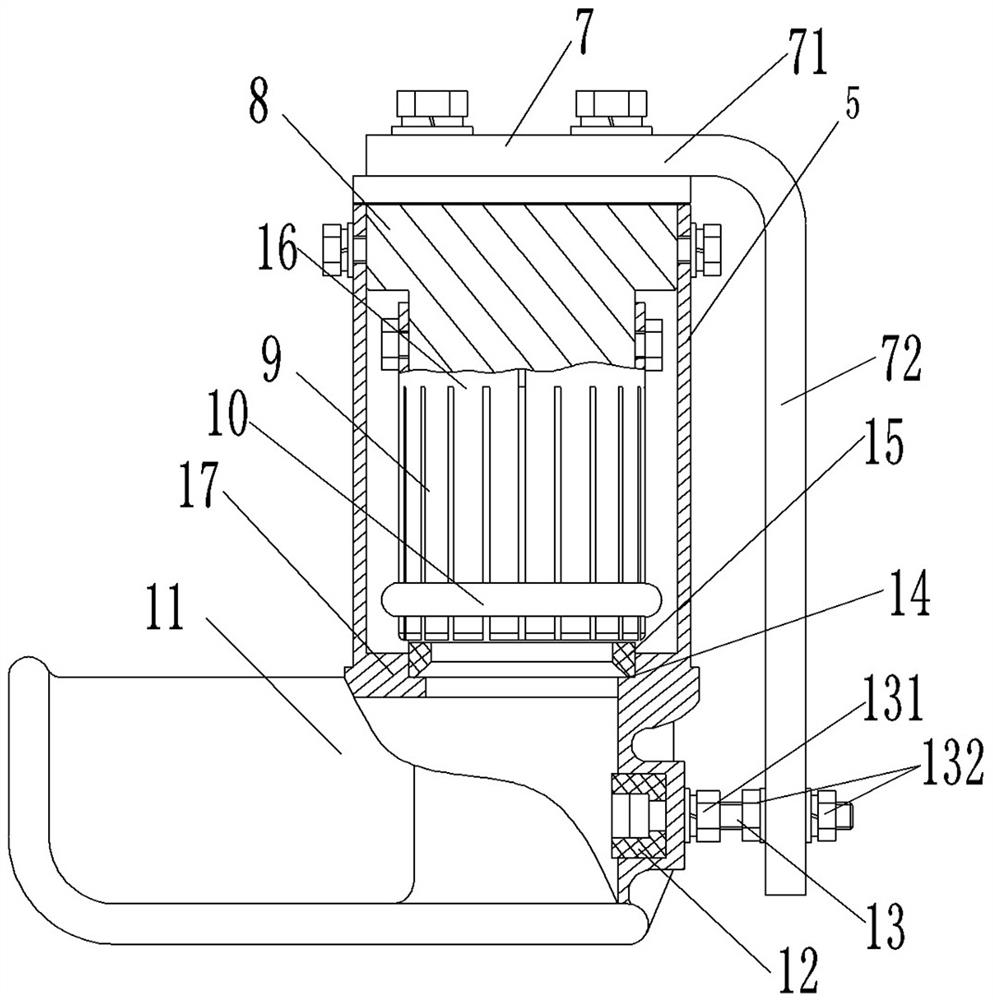

[0065]In the static contact head 2 of the ground switch provided by the present invention, an elastic buffer member 12 is disposed on the closed end of the guide channel, the elastic buffer member 12 being arranged in the guide channel, and the moving contact swing into the guide channel and moves to the guide channel. At the end, it will be equipped with the elastic buffer 12 elasticized, and the movable contact is slowed down and stopped. It is convenient for the next step inserting the upper tubular portion 5 to electrically conductive connection with the inside. The movable contact is buffered by the elastic buffer 12 positive to guide the guide channel, and the elastic buffer 12 of the appropriate elastic coefficient is selected, and the mounting is also convenient, and it is not easy to cause scratch wear, reducing the moving contact. The additional wear of the head is guaranteed to the life of the moving contact.

[0066]In this embodiment, the ground switch is a straight-grade ...

specific Embodiment 2

[0081]The difference from 1 of the examples is mainly in: in Example 1, the elastic buffer member is a rubber member. In the present embodiment, the elastic buffer member is a compressive spring, and the two-way spring of the bottom portion of the chassis is fixed to the closed end by the pressure plate, and the pressure plate is fixed to the closed end by fastening screw.

specific Embodiment 3

[0083]Its difference from the first embodiment is mainly in: in Example 1, the elastic buffer member is detachable in the groove by fastening bolt. In the present embodiment, the rubber member as an elastic buffer can also be tightly inserted in the groove, at this time, since the rubber member is often impacted, it will force it to press the recess, and the rubber member is not easy. Unexpected fallfield.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com