Automatic paint spraying device for glass products

A technology for automatic painting and glass products, applied in the direction of spraying devices, etc., can solve the problems of waste of paint raw materials, etc., to achieve the effects of avoiding paint waste, reducing manufacturing costs, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following is further described in detail through specific implementation methods:

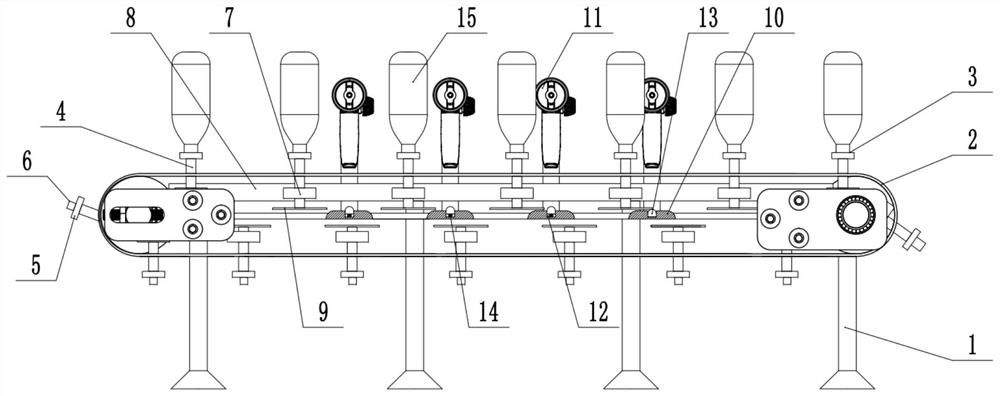

[0022] The reference signs in the drawings of the description include: frame 1, conveyor belt 2, support base 3, support rod 4, support plate 5, protrusion 6, spur gear 7, spur rack 8, trigger plate 9, trigger table 10 , Spray paint head 11, chute 12, push button 13, clip spring 14, glass bottle 15.

[0023] The embodiment is basically as attached figure 1 As shown: the automatic painting device for glass products, including a frame 1, and the top of the frame 1 is fixedly connected with a plate conveyor belt 2 by bolts. Sixteen groups of support seats 3 for supporting glass bottles 15 are provided at equal intervals on the conveyor belt 2 .

[0024] Each support base 3 includes a support rod 4, the support rod 4 is horizontally connected to the conveyor belt 2, the top of the support rod 4 is welded and fixed with a support plate 5, and the top of the support plate 5 is welded and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com