Rock wool board waterproof reinforcing edge sealing equipment and edge sealing process thereof

A technology of edge banding equipment and rock wool board, which is applied in the direction of coating, pretreatment surface, spray booth, etc., can solve the problems that affect the performance and safety of the rock wool board, and the low strength around the rock wool board, so as to achieve high production efficiency and avoid Collapse, avoid damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

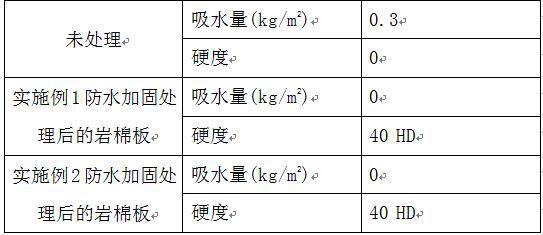

Embodiment 1

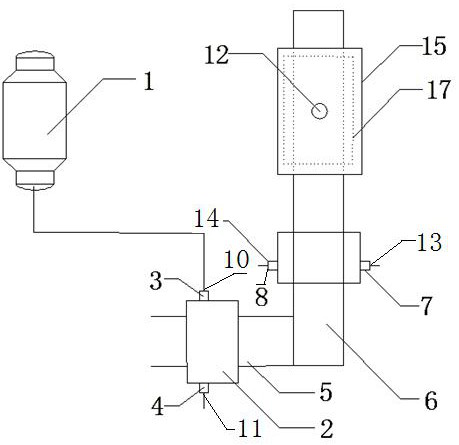

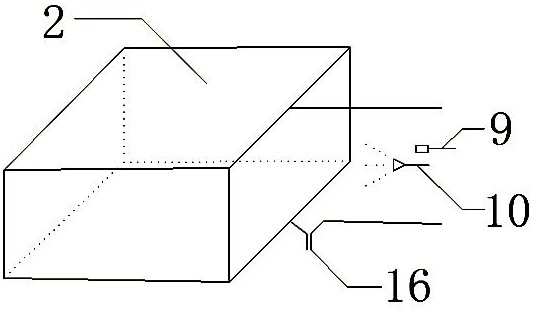

[0026] In this embodiment, a rock wool board waterproof reinforcement edge banding equipment and its edge banding process, refer to the attached Figure 1-2 , including waterproof and reinforced edge banding material storage tank, the first spraying mechanism, the second spraying mechanism, high / low temperature ventilation and curing mechanism, the above four mechanisms are controlled by the PLC controller, and the waterproof and reinforced edge banding material of rock wool board The solvent is a low boiling point solvent. The specific edge banding reinforcement process is as follows:

[0027] 1) Spraying on the left and right sides of the rock wool board

[0028] The 10cm thick rock wool board 2 moves to the first spraying station at a speed of 5m / min under the drive of the first running track 5. When the photoelectric sensor switch 9 of the first spray gun 10 and the second spray gun 11 senses the rock wool board 2 When passing by, the first spray gun 10 and the second sp...

Embodiment 2

[0034] The difference between a rock wool board waterproof and reinforced edge banding equipment and its edge banding process in this embodiment is that the solvent used in the rock wool board waterproof and reinforced edge banding material is a high boiling point solvent. The process of this embodiment Parameters are different from Example 1, specifically as follows:

[0035] 1) Spraying on the left and right sides of the rock wool board

[0036] The 5cm thick rock wool board 2 moves to the first spraying station at a speed of 4m / min under the drive of the first running track 5. When the photoelectric sensor switch 9 of the first spray gun 10 and the second spray gun 11 senses the rock wool board 2 When passing, the first spray gun 10 and the second spray gun 11 start the spraying process, and the rock wool waterproof and reinforced edge banding material is sprayed on both sides of the rock wool board 2 in the shape of "1" through the spray gun nozzle, and the spraying speed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com