Automatic dismounting mechanism for test fixture

A technology for automatic disassembly and testing of fixtures, which is applied in the direction of manufacturing tools, metal processing, and metal processing equipment. It can solve problems such as the inability to guarantee test accuracy, improve disassembly efficiency, realize the disassembly process, and achieve vertical stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

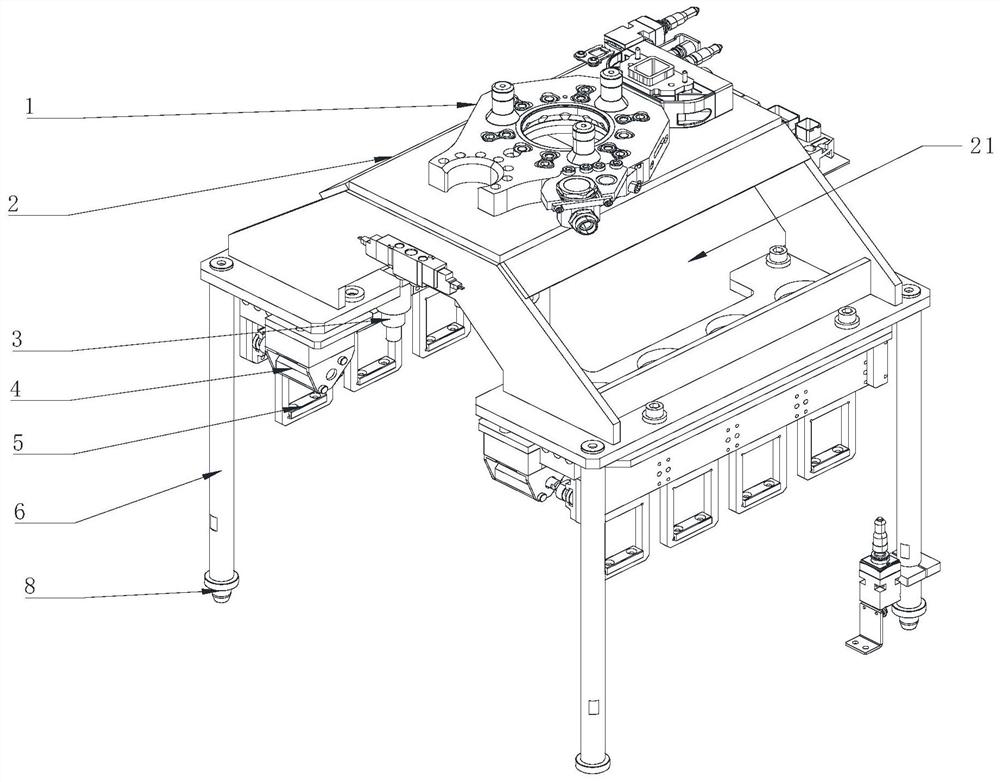

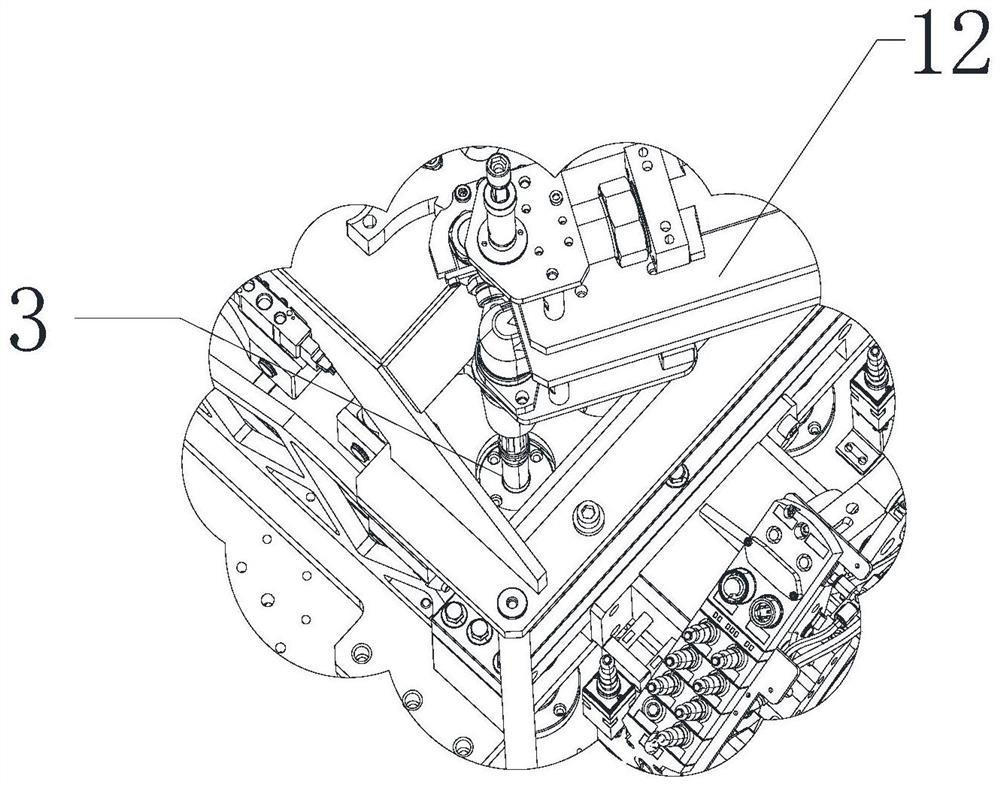

[0040] The automatic disassembly mechanism of the test fixture in this embodiment includes a fixed frame 2, a plurality of support rods 6, a robot switch plate 1, a lateral push assembly 4, a plurality of ejection assemblies 3, and a plurality of hook units 5, see figure 1 .

[0041] A plurality of support rods 6 are vertically arranged below the fixed frame 2, and the support rod 1 stands on the detection platform to realize the support of the fixed frame 1. Positioning pins 8 are arranged below the support rods 6, and the positioning pins 8 are set in the Match the guide holes on the inspection tooling.

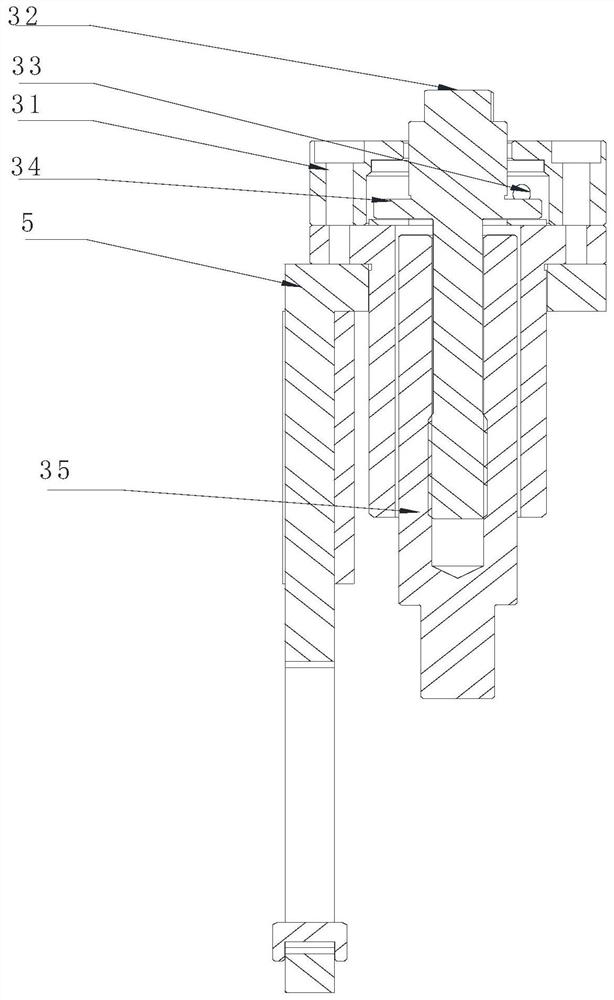

[0042] The top of fixed mount 6 is provided with hollow area 21, and tooling dismantling tightening gun 9 can pass through described hollow area 21 and be connected with the upper end of transmission rod 32 from top to bottom.

[0043] The robot switching panel 1 is arranged above the fixed frame 2 to realize quick connection with the industrial robot.

[0044] The latera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com