A manufacturing process of wireless glue collage covering veneer

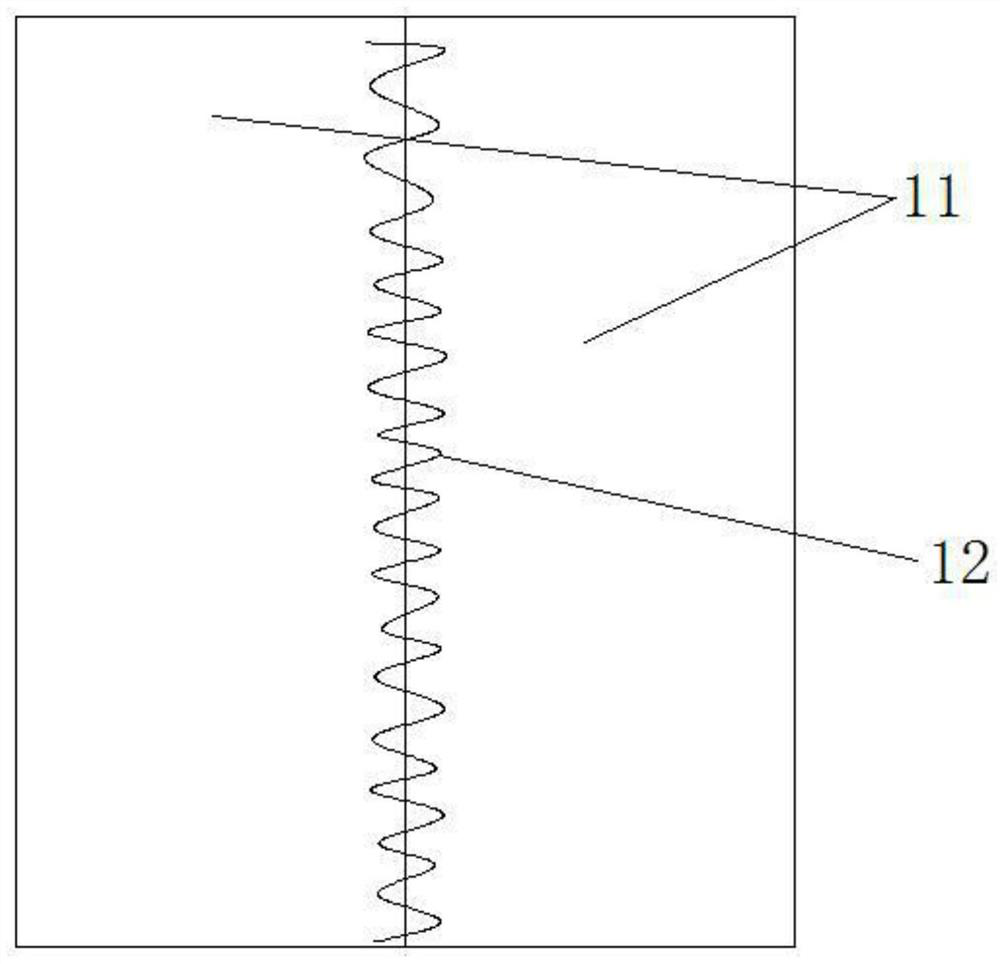

A manufacturing process and technology of wireless glue, applied in the direction of manufacturing tools, wood processing appliances, wood veneer bonding, etc., can solve the problems affecting the appearance and grade of products, residual glue line 12, etc., to achieve a reasonable and diversified wood grain The effect of style, low cost and rational use of veneer resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

[0039] like Figure 2-Figure 15 As shown in the figure, a manufacturing process of veneer with wireless glue collage includes the following steps:

[0040] ① Stack multiple pieces of veneer 1 together;

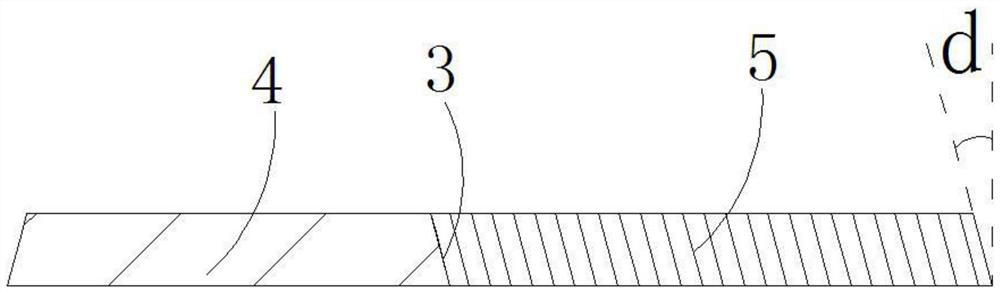

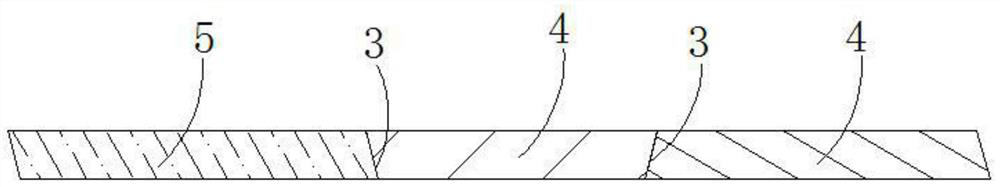

[0041] 2. Cut the original veneer 1 into a trapezoidal veneer 4 or a parallelogram veneer 5, and the two sides of the trapezoidal veneer 4 and the parallelogram veneer 5 all form a beveled surface 3; the inclination angle d of the beveled surface 3 is 12~18 degrees. Preferably, the inclination angle d of the chamfered surface 3 is 15 degrees.

[0042] ③ The at least two veneers to be glued together are attached to each other in the horizontal direction, and the veneers to be glued together are at least one of trapezoidal veneer 4 and parallelogram veneer 5, and the joints of two adjacent veneers to be glued together pass the oblique cut surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com