Shield muck brick-making recycling method

A muck and shield technology, which is applied in the field of shield muck to make bricks, can solve problems such as unstable accumulation of dregs containing water, occurrence of landslides, landslides, waste of land resources, etc., to improve equipment processing capacity and reduce siltation , Improve the effect of sand quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

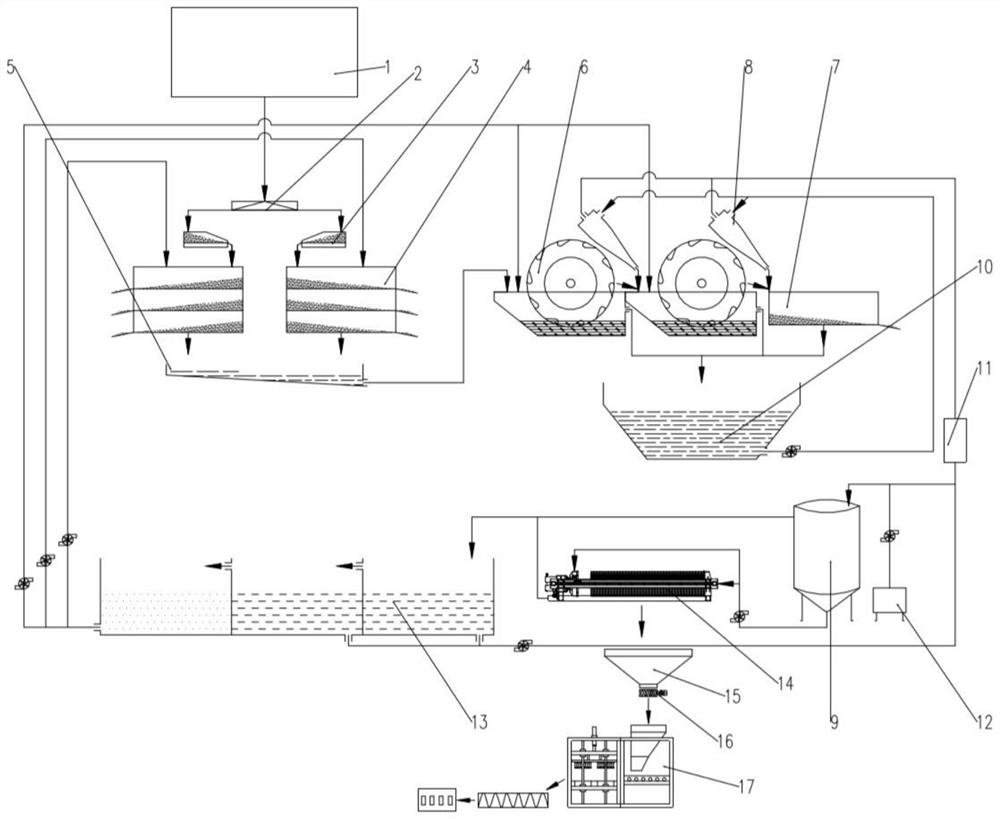

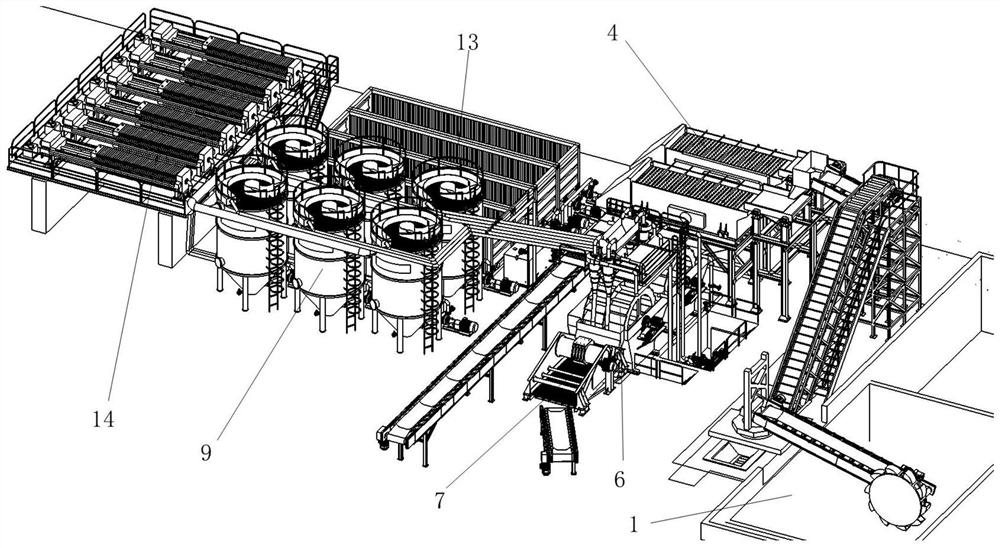

[0041] Combine below figure 1 , figure 2 The present invention will be described in detail.

[0042] A method for recycling bricks made from shield muck comprising the following steps:

[0043] Step A: screen the shield muck after leaving the well;

[0044] Step B: Screening to obtain coarse sand and screened mud, storing the coarse sand, and washing the screened mud;

[0045] Step C: washing the sand to obtain fine sand and sand washing mud, storing the fine sand, and swirling the sand washing mud;

[0046] Step D: Swirl to obtain sandy underflow and swirling mud, wash the sandy underflow again, and flocculate the swirling mud;

[0047] Step E: flocculation to obtain the supernatant liquid and the thick mud in the lower layer, the supernatant liquid is precipitated, and the thick mud is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com