Hybrid electric vehicle power upshift process control method

A hybrid vehicle and process control technology, applied in hybrid vehicles, motor vehicles, transportation and packaging, etc., can solve the problems of shifting shock, reduced ride comfort, slow transient torque response speed of the engine, etc. The effect of small shift shock and improved ride comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

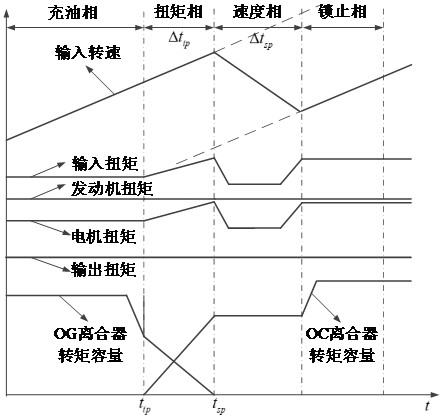

[0020] like figure 1 As shown, the powered upshift process includes four phases, namely, the oil filling phase, the torque phase, the speed phase and the lock-up phase. Based on the HTCU (Hybrid-vehicle & Transmission Control Unit) control system solution, the present invention provides a hybrid electric vehicle on the basis that the driving power demand, the coordinated control of the torque of the engine and the motor, and the shift process control are all directly controlled by the HTCU There is a power upshift process control method, which is mainly controlled by the motor for auxiliary torque.

[0021] First, HTCU according to the accelerator pedal opening and speed by look-up table Get the output torque of the transmission ;

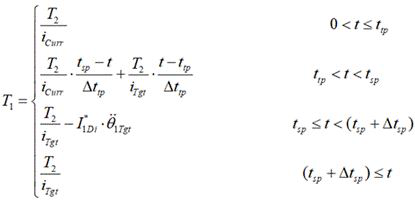

[0022] Then, the oil-extended phase ( ), torque phase ( ), velocity phase ( ) and the lock-up phase ( ) four stages of input torque :

[0023]

[0024] Finally, according to the calculated input torque , the motor torque is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com