Middle and long distance heat supply transmission system used for fused salt

A transmission system, long-distance technology, applied in the field of energy storage and heating, which can solve the problems of high operation and maintenance costs, and difficulty in recycling molten salt.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

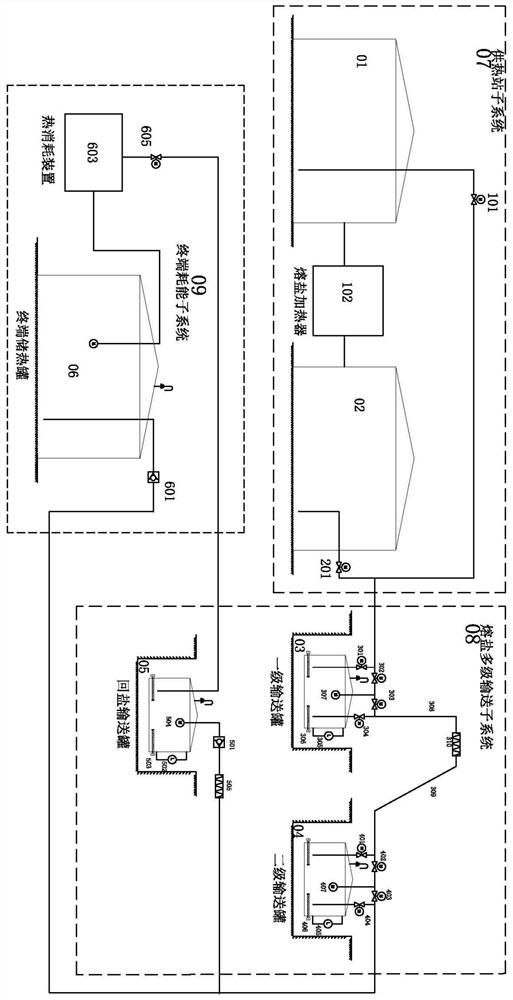

[0031] as attached figure 1 Shown: a mid-to-long-distance heat supply transmission system for molten salt, including: heat supply station subsystem 07, graded conveyance subsystem 08, and terminal energy consumption subsystem 09.

[0032] The heating station system includes: a cold salt tank 01 of the heating station, a molten salt heater 102, a salt return valve 101 of the cold salt tank of the heating station, a hot salt tank 02 of the heating station, and a salt supply valve 201 of the hot salt tank;

[0033] The molten salt multi-stage transport subsystem includes: a primary transport tank 03, a heating molten salt pipeline 308, a secondary transport tank 04, and a return salt transport tank 05;

[0034] The terminal energy consumption system includes: a terminal heat storage tank 06, a heat consumption device 603;

[0035] The location of the primary delivery tank 03 is lower than that of the hot salt tank 02 of the heating station, and the hot salt of the heating tank c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com