Brinell hardness indentation diameter measurement auxiliary device

A technology of diameter measurement and auxiliary devices, which is applied in the direction of mechanical diameter measurement and testing material hardness to achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

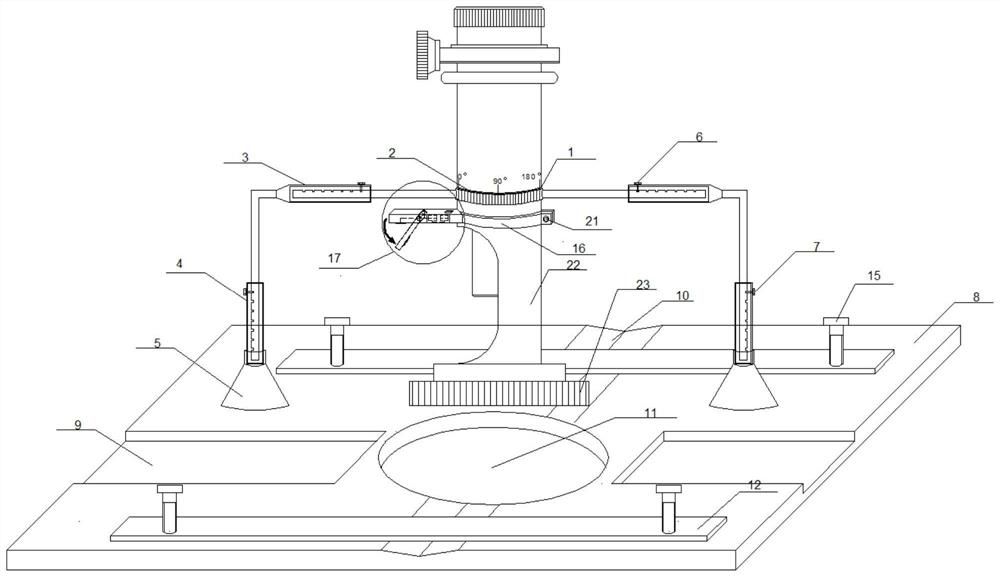

[0017]The present invention will be described in more detail below with reference to the accompanying drawings:

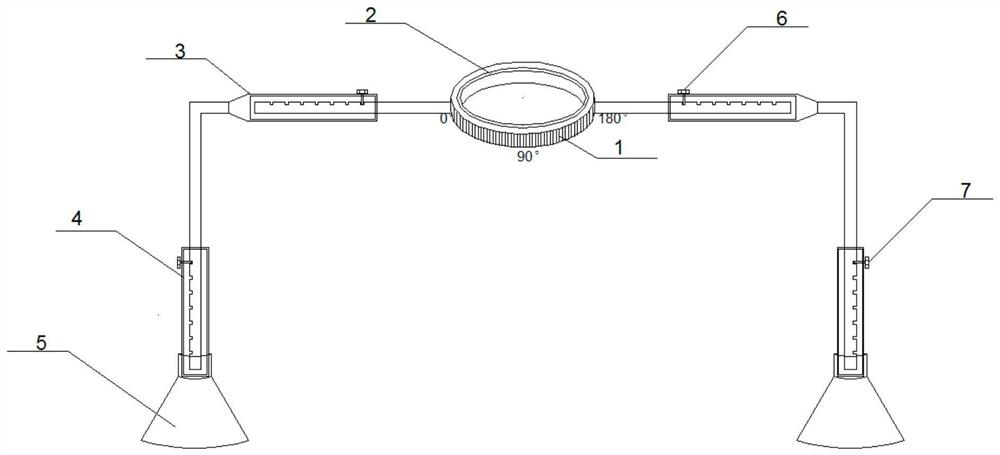

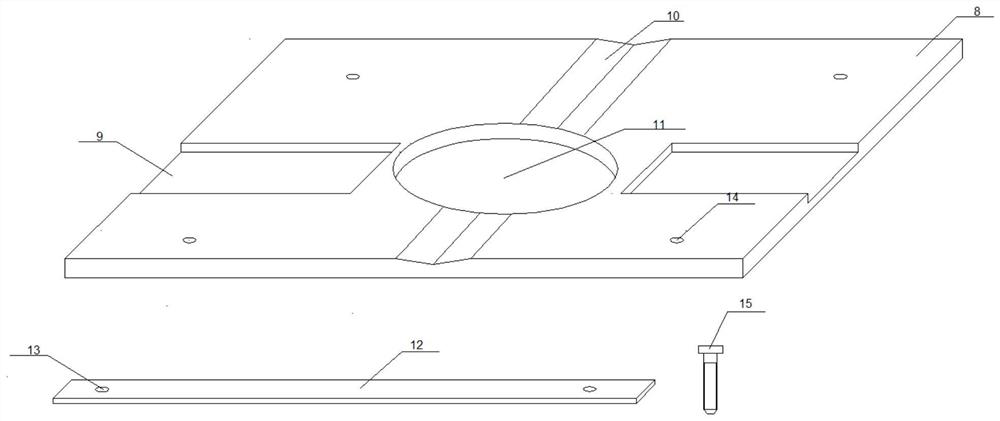

[0018]CombineFigure 1-4, A brine hardness indentation diameter auxiliary measuring device, and a support rod assembly, a bottom plate assembly, and a lighting device assembly are included. Support rod assemblyfigure 2 The annular clamp 1 in the middle belt angle scale is inserted into the ring groove 2, and the loop 2 is fixed to the measurement microscope mirror 22, and the annular clamp 1 with angular scale 1 is rotated 360 ° on the loop 2, with angular scale The annular clamp 1 is rigidly connected to the horizontal telescopic rod 3, and the other end of the horizontal telescoping rod 3 is connected to the vertical stretch rod 4, and the vertical stretch rod 4 is rigidly connected to the magnetic suction cup 5, horizontally telescopic rod 3 And the vertical stretch rod 4 adjusts the position of the measurement microscope in the space by horizontal stretching rod englee 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com