Transformer production spraying device

A spraying device and transformer technology, applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve problems such as spraying dead spots and affecting spraying effects, achieve stable and accurate spraying without offset, avoid spraying dead ends, and facilitate personnel. effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

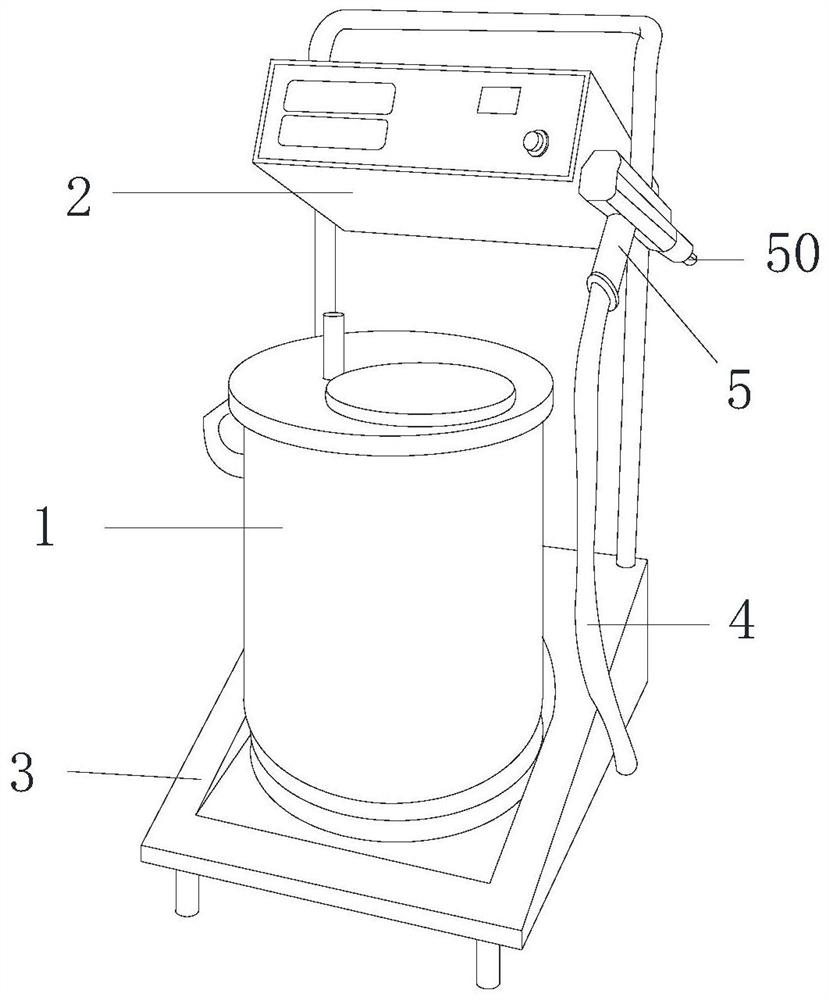

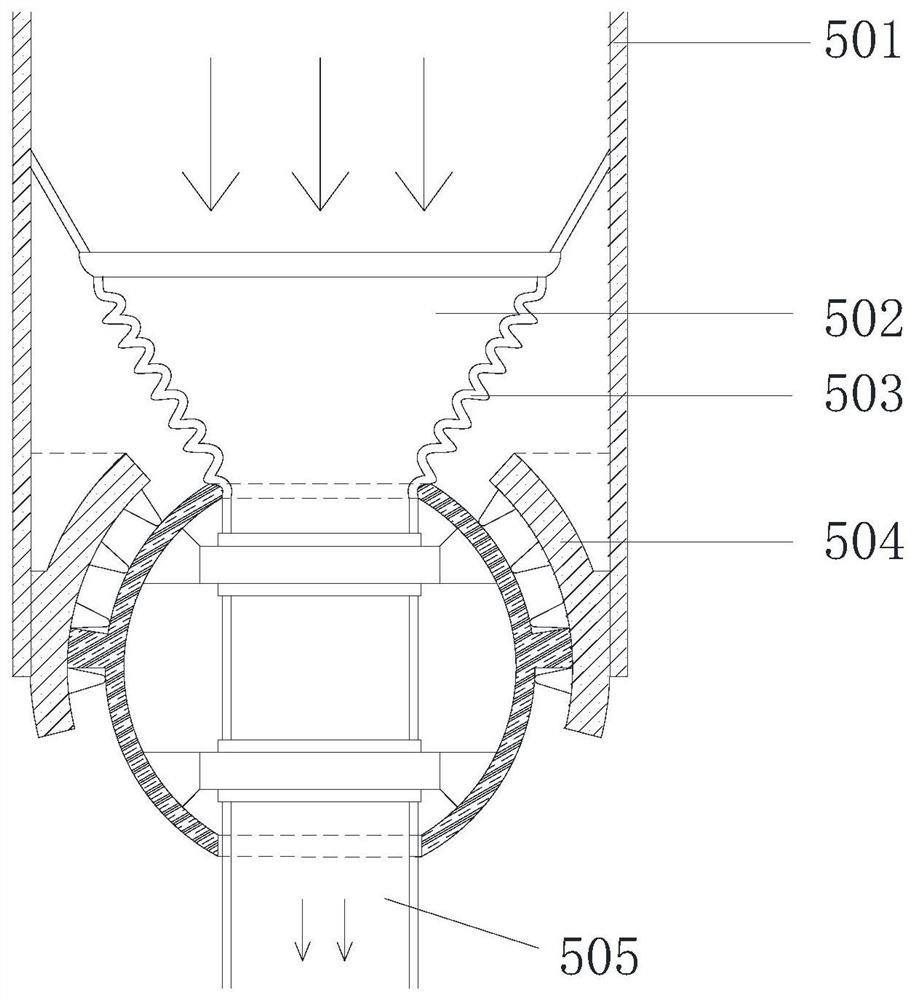

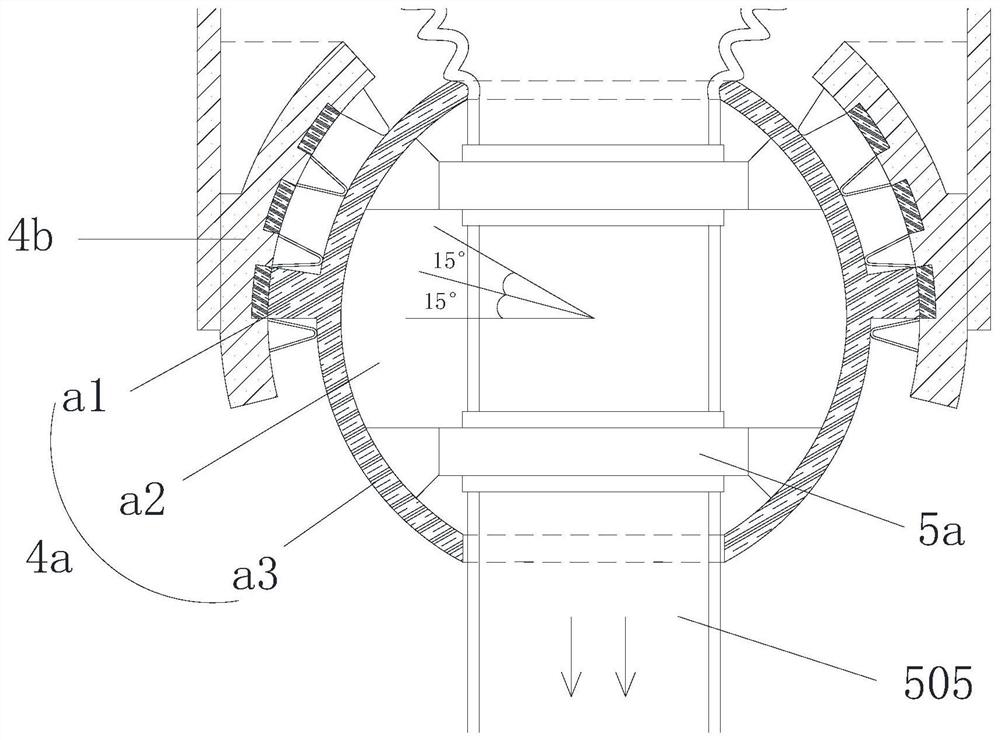

[0024] see Figure 1-Figure 5 , a spraying device for transformer production, the invention provides a spraying device for transformer production, its structure includes a spraying material barrel 1, a control electric box 2, a fixed chassis 3, a spraying connecting pipe 4, a spraying gun 5, the spraying material barrel 1. The bottom is set on the upper surface of the fixed base frame 3. The control electrical box 2 is set above the spraying material barrel 1, and is connected with the spraying material barrel 1 through a circuit. One end of the spraying connection pipe 4 passes through the bottom of the fixed base frame 3. It is connected to the spraying material barrel 1, and the other end is connected to the spraying gun 5. The spraying gun 5 is hung on the side of the control electric box 2. It is characterized in that: the spraying gun 5 is provided with an adjusting paint nozzle 50, and the adjusting The paint nozzle 50 is connected through the spray gun 5, and is connec...

Embodiment 2

[0027] see figure Figure 5 , a transformer production spraying device, the invention provides a transformer production spraying device, Its structure includes Angle stabilization component b3, the angle stabilization component b3 includes an inner hollow groove b31, an adjustment cover b32, and an adjustment spring b33, the inner hollow groove b31 and the outer ring b2 are in an integrated structure, and the inner hollow groove b31 is arranged on the outer outer ring Inside b2, the number of the inner hollow groove b31 is the same as that of the adjustment cover b32, and one end of the inner side of the adjustment cover b32 is embedded in the inner hollow groove b31, and is movably connected by the adjustment spring b33, which is arranged inside the adjustment cover b32.

[0028] On the basis of Embodiment 1, in order to make spraying more stable after spraying out the rotation angle of the hard tube 505, an angle stabilization component b3 is added. When rotating, the angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com