Energy storage mechanism for spring operating mechanism

A technology of operating mechanism and energy storage mechanism, which is applied in the direction of protection switch operation/release mechanism, etc., and can solve the problems of poor stability of spring operating mechanism and large lateral force component of energy storage pull rod, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

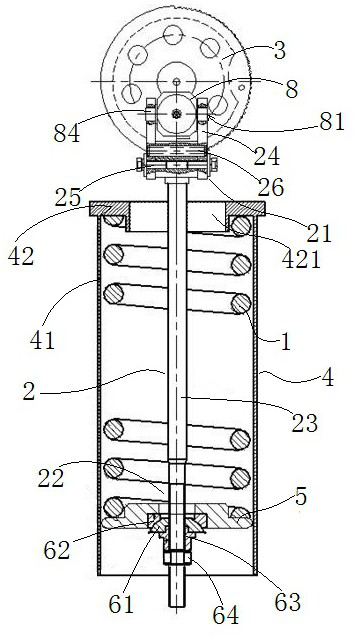

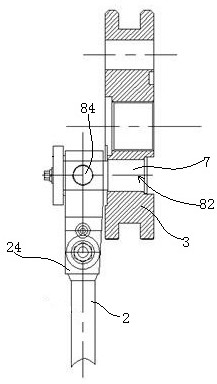

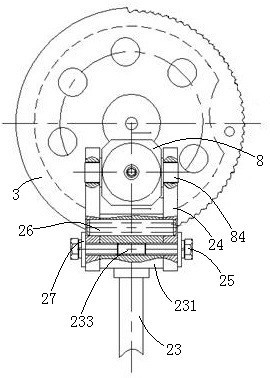

[0037]Such asFigure 1 to 9 As shown, the spring optic mechanism includes a frame, the energy storage spring 1, the energy storage rod 2, the drive wheel 3, wherein the transmission wheel 3 rotates on the rack, and the rack is provided with the drive wheel. Mounting axis. A spring barrel 4 is also provided on the frame, and the energy storage spring 1 is disposed in the spring barrel 4, and the upper end of the energy storage rod 2 is connected to the drive wheel 3, and the lower end is a spring fit end 22, the spring fit end 22 The spring pressure plate 5 is provided, and the lower end of the energy storage spring 1 is in contact with the spring block, and the upper end is in contact with the spring cartridge 4, and the spring pressure plate 5 is guided in the extending direction of the reservoir spring 1 in the spring cartridge 4. In the present invention, the extending direction of the energy storage spring 1 is a compression extension direction of the storage energy spring 1. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com