Anti-disassembly structure of electronic cigarette

An electronic cigarette and tamper-proof technology, which is applied in the field of electronic cigarettes, can solve problems such as lack of tamper-proof performance, disassembly, piracy and imitation, and potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

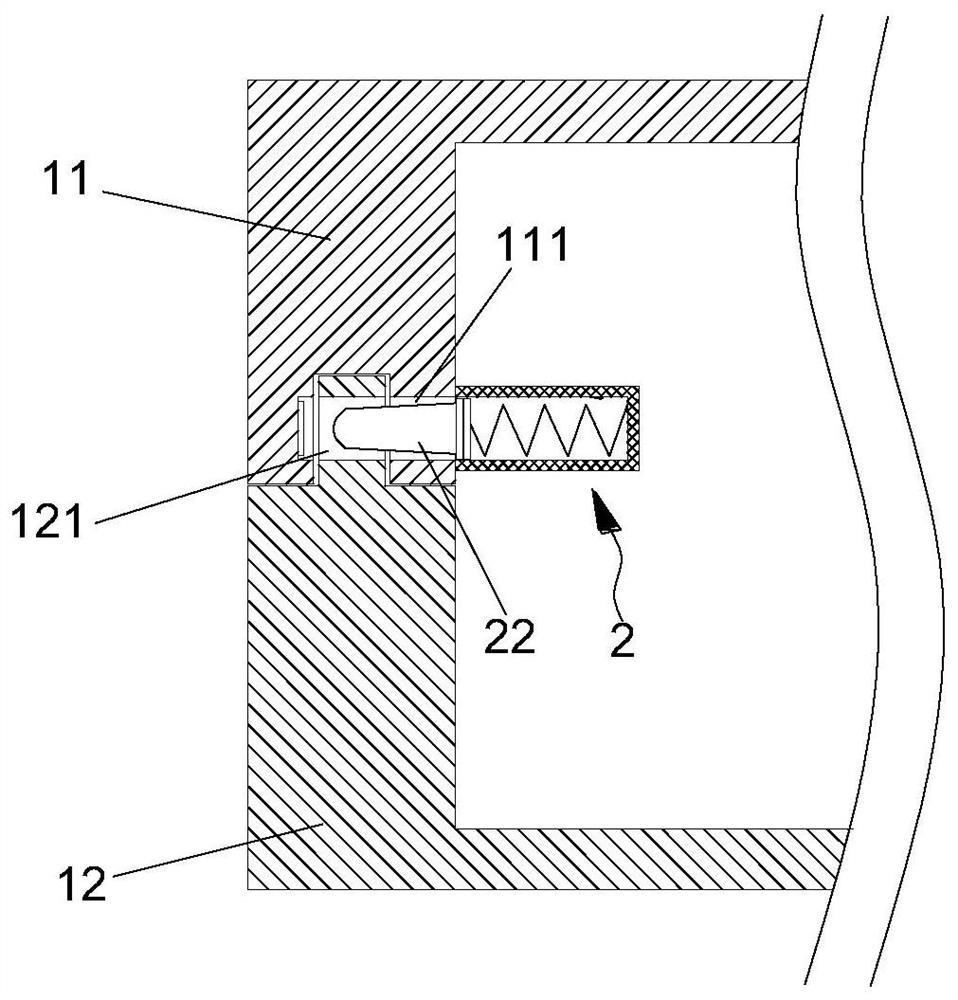

[0044] Please refer to Figure 4 , Figure 5 The trigger mechanism 25 includes an elastic buckle 251 and an electromagnet 252. The elastic buckle 251 is made of metal material and is approximately in a "V" shape, including a fixed end and a movable end. Because the metal material has elasticity, the movable end can be fixed around the fixed end. The wide range of motion makes the elastic buckle 251 deform within a certain range. The elastic buckle 251 is arranged on the side wall of the chute 211, and is close to the bottom of the chute 211, the fixed end of the elastic buckle 251 is connected with the side wall of the chute 211, and the movable end is naturally opened to resist and limit the push plate 23 . The electromagnet 252 is arranged on the side wall of the chute 211, corresponding to the movable end of the elastic buckle 251, and can generate magnetic force to attract the movable end of the elastic buckle 251 when electrified.

[0045] The trigger mechanism 25 of t...

Embodiment 2

[0047] Trigger mechanism 25 comprises cam (not shown in the figure) and motor (not shown in the figure), and cam is arranged on the side wall of chute 211, and near the bottom of chute 211, its axis position and The side wall is rotatably connected, the long axis end of the cam is used to resist and limit the push plate 23, and the motor and the cam are linked to drive the cam to rotate.

[0048] The trigger mechanism 25 of this embodiment works specifically in this way. When the cam rotates until the long axis end is in vertical contact with the push plate 23, the cam pushes against the push plate 23 and limits the position of the push plate 23, so that the push plate 23 is close to the chute. At the bottom of 211, the elastic member 24 is in a compressed state. When the motor drives the cam to rotate, the cam is gradually deflected, so that the long axis end is gradually biased. When the cam is tilted to a certain angle, the push plate 23 moves outward along the chute 211 un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com