Beneficiation process and device for chemical-grade chromium concentrate powder

A chromium concentrate and chemical technology, which is applied in the field of beneficiation process and device of chemical grade chromium concentrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

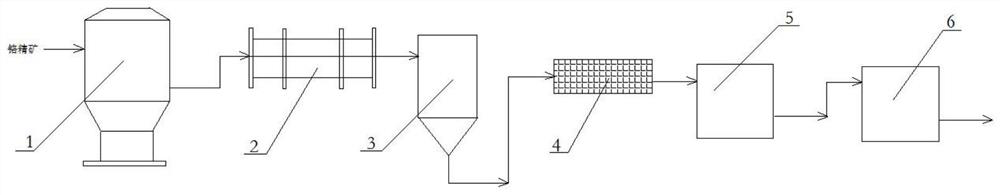

[0032] use figure 1 In the mineral processing device shown, the chrome concentrate is first sent to the three-pass dryer 2 for drying, wherein the fluidized fluidized furnace 1 provides heat source for the three-pass dryer 2, and after drying, it enters the bag filter 3 for dust removal. Then use the square vibrating sieve 4 to sieve out different particle size ranges, which are specifically divided into: chrome concentrate with particle size>0.425mm, 0.2mm≤particle size≤0.425mm, 0.125mm≤particle size<0.2mm, and particle size<0.125mm.

[0033] Put the chromium concentrates of the above four different particle size ranges into the weak magnetic separator 5 respectively, and adjust the different magnetic field strengths of the weak magnetic separator 5 according to the different particle sizes, wherein the particle size > 0.425mm correspondingly adjusts the weak The weak magnetic intensity of the magnetic separator 5 is 4000 gauss; 0.2mm≤particle size≤0.425mm correspondingly adj...

Embodiment 2

[0036] use figure 1 In the mineral processing device shown, the chrome concentrate is first sent to the three-pass dryer 2 for drying, wherein the fluidized fluidized furnace 1 provides heat source for the three-pass dryer 2, and after drying, it enters the bag filter 3 for dust removal. Then use the square vibrating sieve 4 to sieve out different particle size ranges, which are specifically divided into: chrome concentrate with particle size>0.425mm, 0.2mm≤particle size≤0.425mm, 0.125mm≤particle size<0.2mm, and particle size<0.125mm.

[0037]Put the chromium concentrates of the above four different particle size ranges into the weak magnetic separator 5 respectively, and adjust the different magnetic field strengths of the weak magnetic separator 5 according to the different particle sizes, wherein the particle size > 0.425mm correspondingly adjusts the weak The weak magnetic intensity of the magnetic separator 5 is 4200 gauss; 0.2mm≤particle size≤0.425mm correspondingly adju...

Embodiment 3

[0040] use figure 1 In the mineral processing device shown, the chrome concentrate is first sent to the three-pass dryer 2 for drying, wherein the fluidized fluidized furnace 1 provides heat source for the three-pass dryer 2, and after drying, it enters the bag filter 3 for dust removal. Then use the square vibrating sieve 4 to sieve out different particle size ranges, which are specifically divided into: chrome concentrate with particle size>0.425mm, 0.2mm≤particle size≤0.425mm, 0.125mm≤particle size<0.2mm, and particle size<0.125mm.

[0041] Put the chromium concentrates of the above four different particle size ranges into the weak magnetic separator 5 respectively, and adjust the different magnetic field strengths of the weak magnetic separator 5 according to the different particle sizes, wherein the particle size > 0.425mm correspondingly adjusts the weak The weak magnetic intensity of the magnetic separator 5 is 4100 Gauss; 0.2mm≤particle size≤0.425mm correspondingly adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com