Manufacture method of elastomer modified asphalt waterproof coiled materials

A technology of bitumen waterproofing membrane and waterproofing membrane, which is applied in the direction of device and coating for coating liquid on the surface, can solve the problem of different sand volume of waterproofing membrane, uneven sanding volume of waterproofing membrane, and waterproofing membrane. The amount of sanding material cannot be adjusted, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

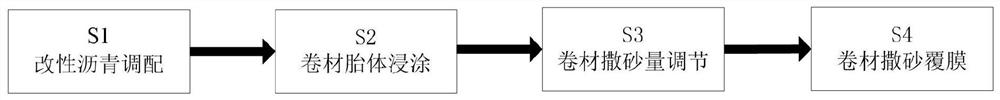

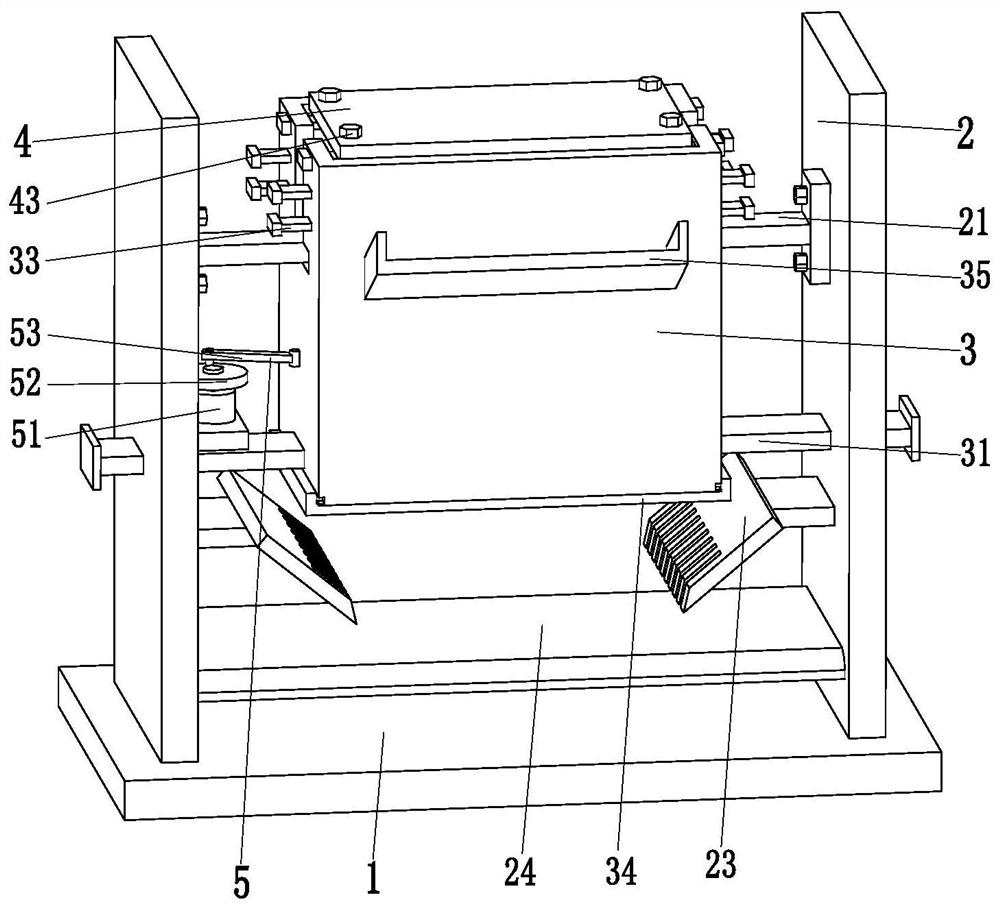

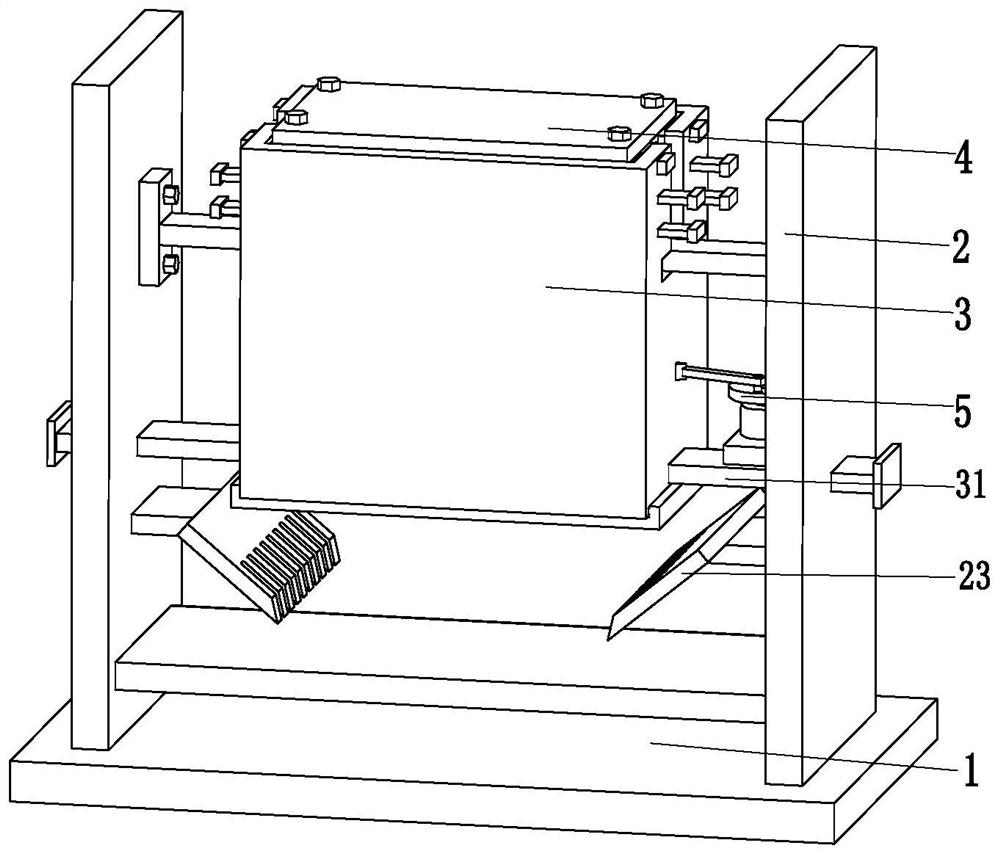

[0034] Such as Figure 2-7As shown, a method for preparing elastomer-modified asphalt waterproof membrane, the preparation method of elastomer-modified asphalt waterproof membrane adopts the following waterproof membrane sanding device, and the waterproof membrane sanding device includes a bottom plate 1 and a side vertical plate 2 , sand box 3, top cover 4 and rocking mechanism 5, on the top of described base plate 1 along its length direction, side vertical board 2 is symmetrically installed, and sand box 3 is arranged between two side vertical boards 2, and sand box 3 It is a square frame structure with an upper end opening. The lower end of the sand box 3 is symmetrically provided with support rods 31. The support rods 31 pass through the side r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com