Riveting-shaping-stretching integrated device

A technology of hot riveting and riveting connection, which is applied in the direction of forming tools, manufacturing tools, metal processing, etc., and can solve the problems of unrealized automatic operation, danger, and backward replacement of riveted connection punches, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

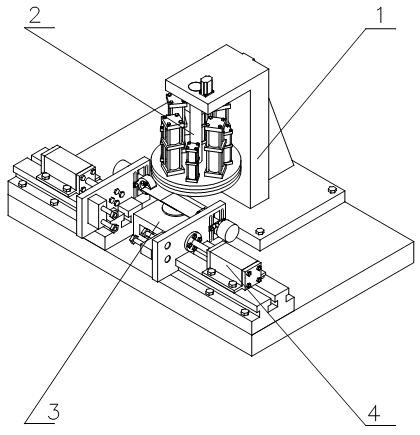

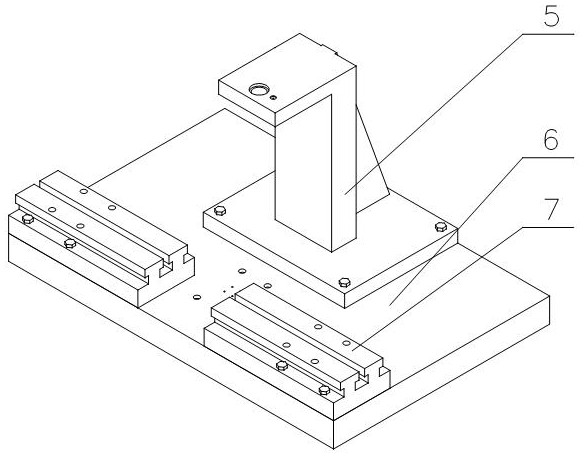

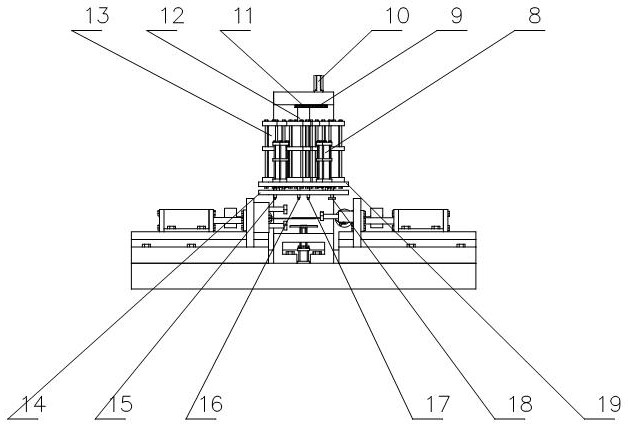

[0012] A riveting-shaping-stretching integrated device, such as figure 1 As shown, the equipment consists of a basic platform mechanism (1), a rivetless punch mechanism (2), a rivetless die mechanism (3), and a clamping and stretching mechanism (4). The connection relationship is as follows: The mechanism (2) is installed on the middle front part of the punch mounting table (5) through the central rotating shaft (12); the rivetless die mechanism (3) is positioned and installed on the bottom plate (6) through the screw holes on the bottom plate (6) , which is specifically positioned in front of the punch mounting table (5), in the middle of the two symmetrical clamping and stretching mechanisms (4), and forms an integral rivetless connection device with the rivetless punch mechanism (2); the two Two symmetrical clamping and stretching mechanisms are respectively installed on the left and right slides (7) of the basic platform mechanism (1); under the joint cooperation of the ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com