A Rapid Polishing and Polishing Method for Large-Aperture Optical Mirrors Based on Multiple Polishing and Polishing Systems

A technology of optical mirrors and optical mirrors, which is applied in the field of rapid polishing of large-diameter optical mirrors, can solve the problems of limited processing cycle production efficiency of optical systems, difficult to meet, and long time-consuming optical processing. , Reduce the effect of work intensity and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

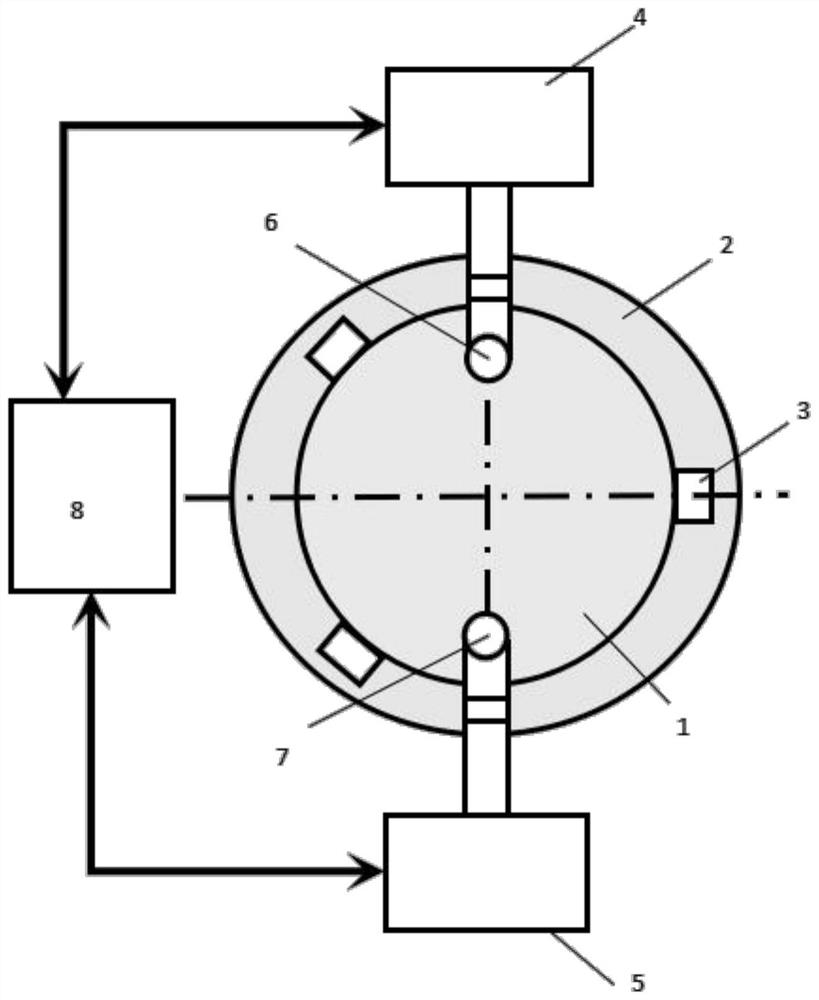

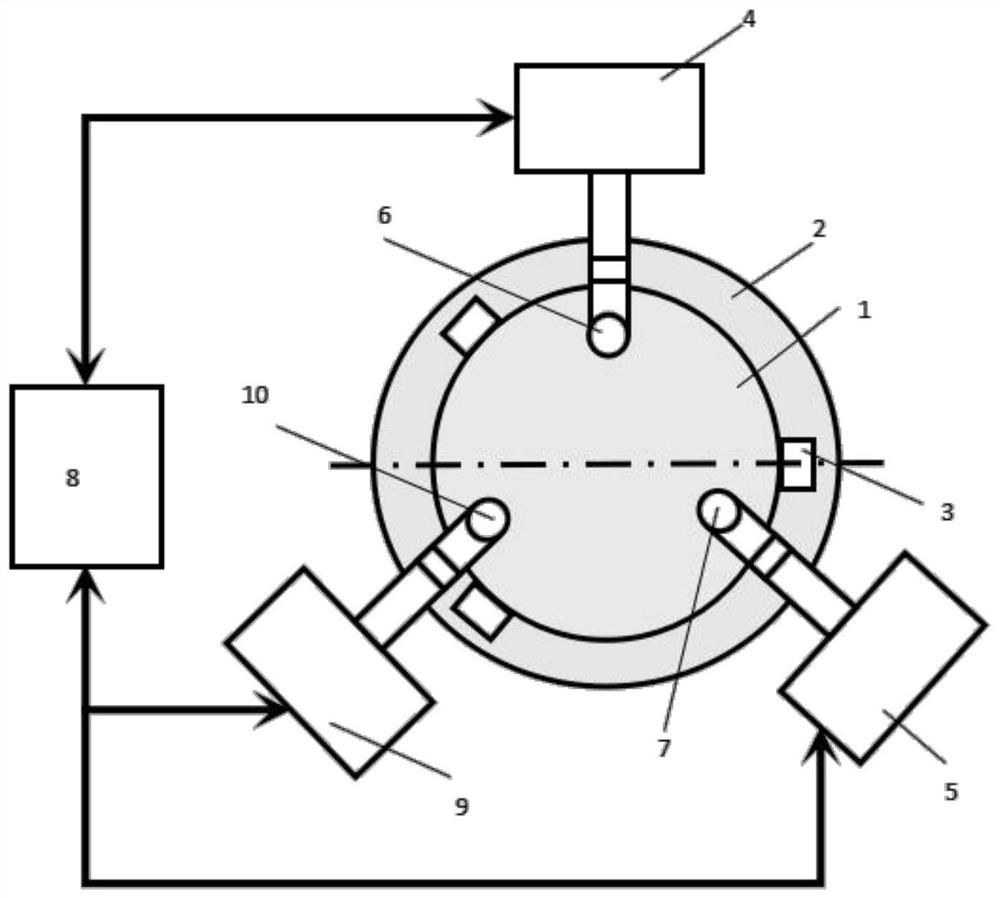

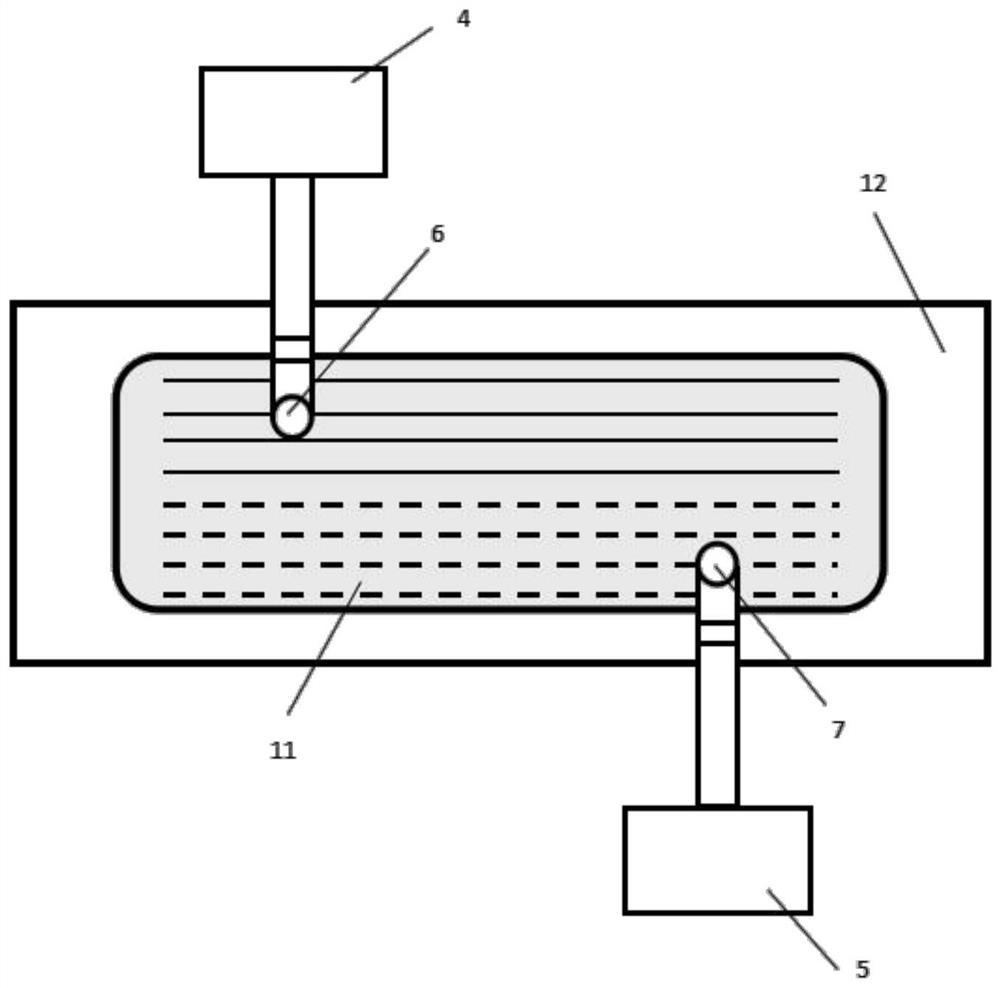

[0036] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

[0037] In order to achieve fast and high-precision large-caliber optical processing, in the time-consuming polishing process, the traditional single polishing system processing is changed, and multiple polishing system combinations are adopted, and multiple polishing systems are realized through numerical control systems and intelligent synchronous control methods. The system works in an orderly manner at the same time, solving the problem of low polishing efficiency, greatly improving production efficiency and reducing costs.

[0038]Based on the state of the high, medium and low frequency bands of the mirror surface, different sizes and characteristics of polishing tools can be used. Such as metal grinding discs, airbag heads, magnetorheological, asphalt discs, etc., to achiev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com