Automatic bag filling mechanism based on woven bags and control method of automatic bag filling mechanism

A woven bag, automatic technology, applied in the field of automatic bag filling mechanism based on woven bags and its control field, can solve the problems of difficulty in manual bag filling, easy product accumulation, and large friction force of the triangle belt, so as to improve the success rate of bag filling. , the effect of eliminating gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with embodiment the present invention is described in further detail.

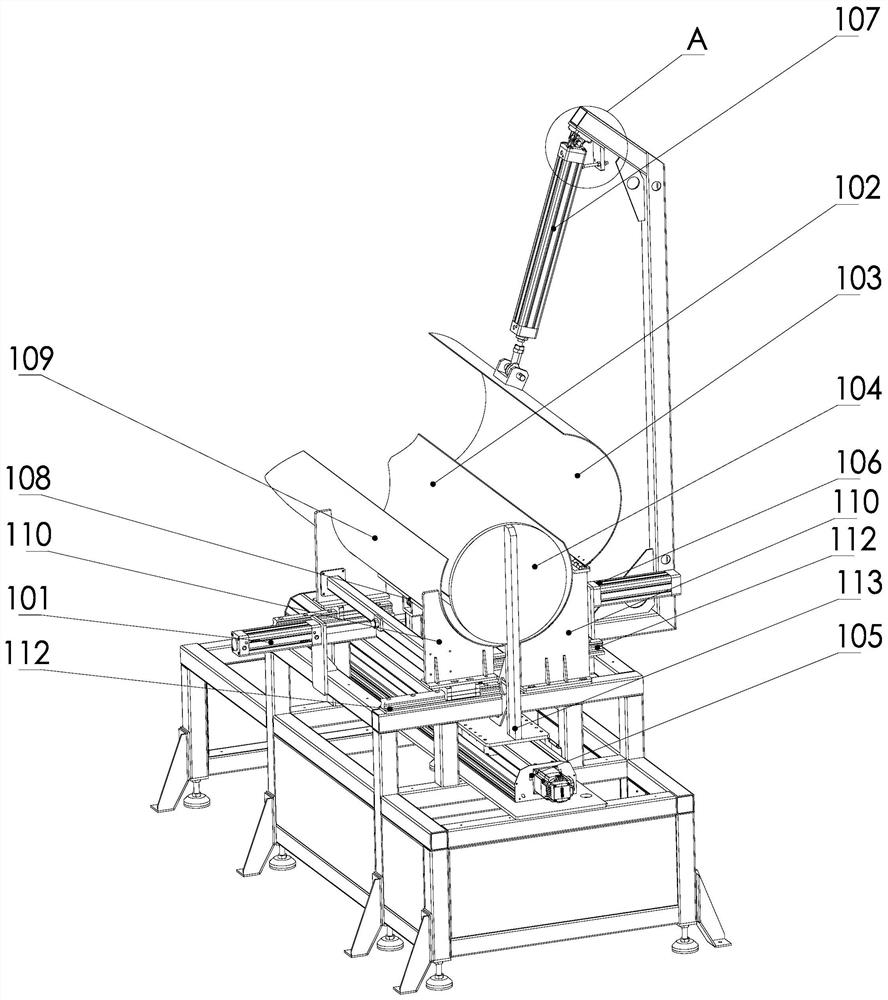

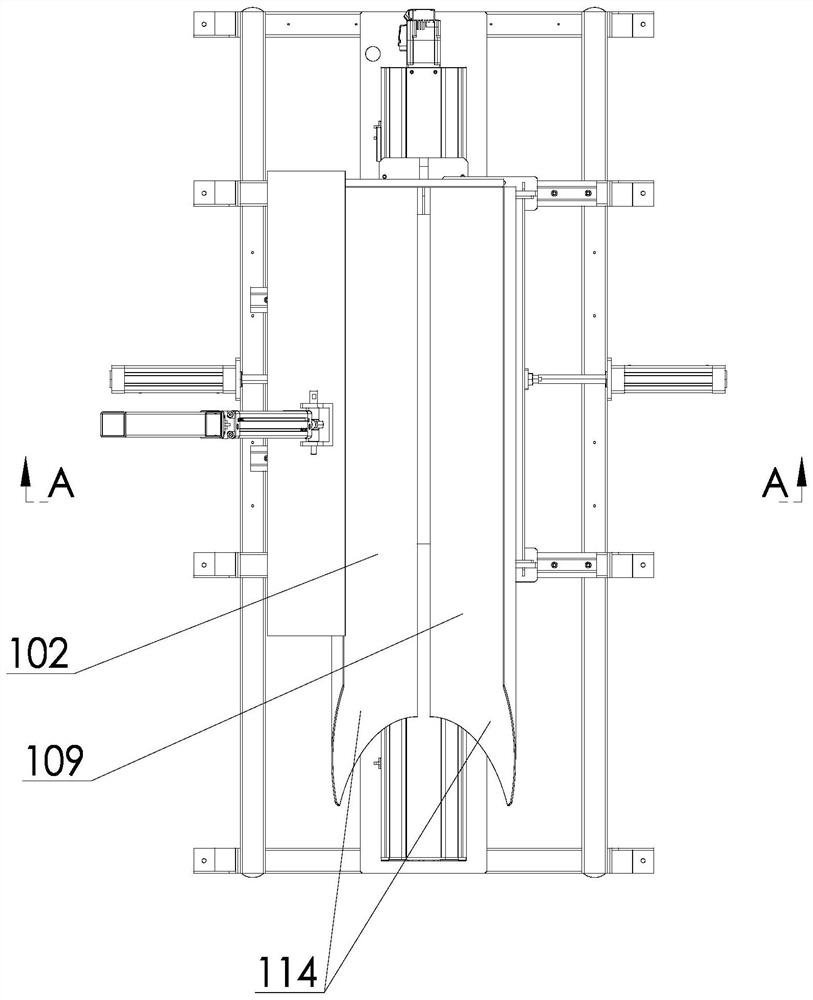

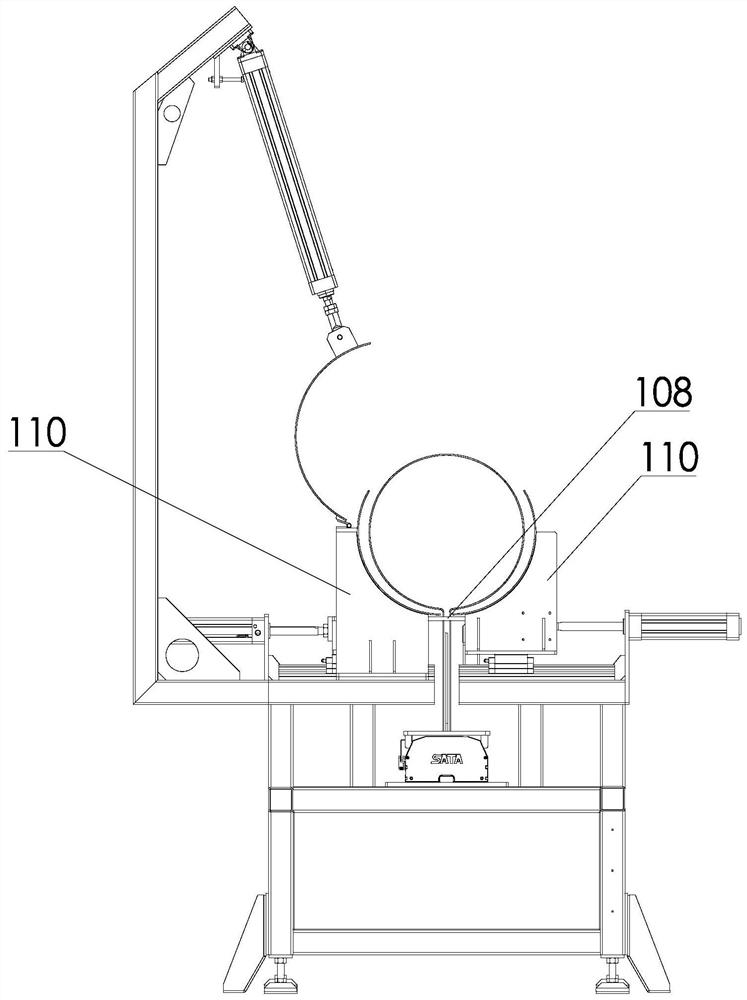

[0040] This embodiment proposes an automatic bag filling mechanism based on woven bags, such as Figures 1 to 6 As shown, it includes a frame, a movable barrel wall 109, a fixed barrel wall 102, a baffle plate 108, a push plate 104, a gland 103 and a plurality of driving components.

[0041] The movable barrel wall 109 and the fixed barrel wall 102 are symmetrically arranged on the frame, the movable barrel wall 109 is slidably connected on the frame by the slide rail 112, the movable barrel wall 109 and the slide rail 112 are connected by a support 110, and the fixed barrel wall The wall 102 is fixed to the frame by a support 110 . A driving assembly 101 is fixed on the frame, and the driving assembly 101 is used to control the movable barrel wall 109 to approach and separate from the fixed barrel wall 102 . The movable barrel wall 109 and the fixed barrel wall 102 form the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com