Relay type vertical conveying system and conveying method thereof

A conveying system and box conveying technology, which is applied in the field of conveyors, can solve the problems of high verticality requirements of shafts, increased conveying distance, dependence on shafts, etc., and achieve the effect of improving actual conveying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

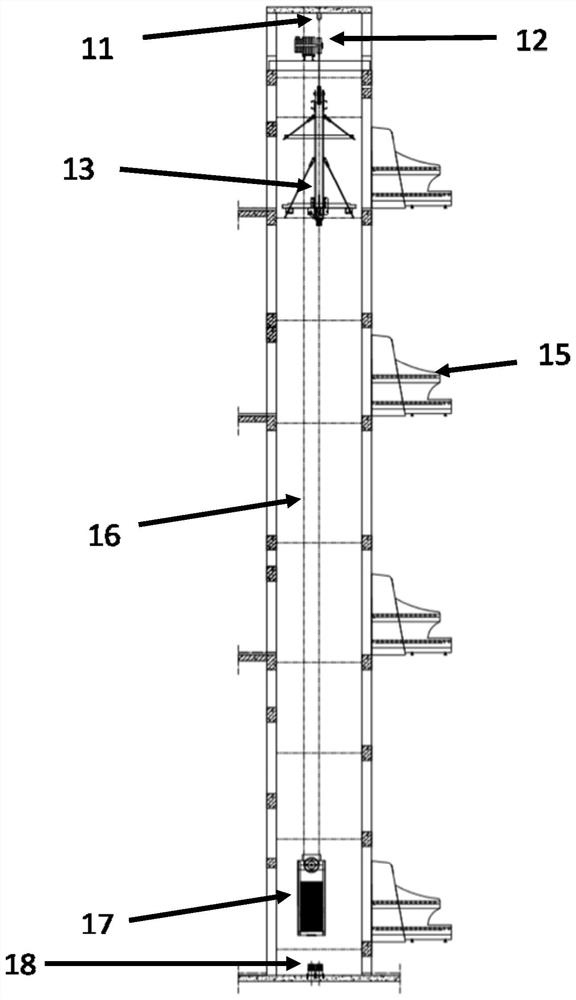

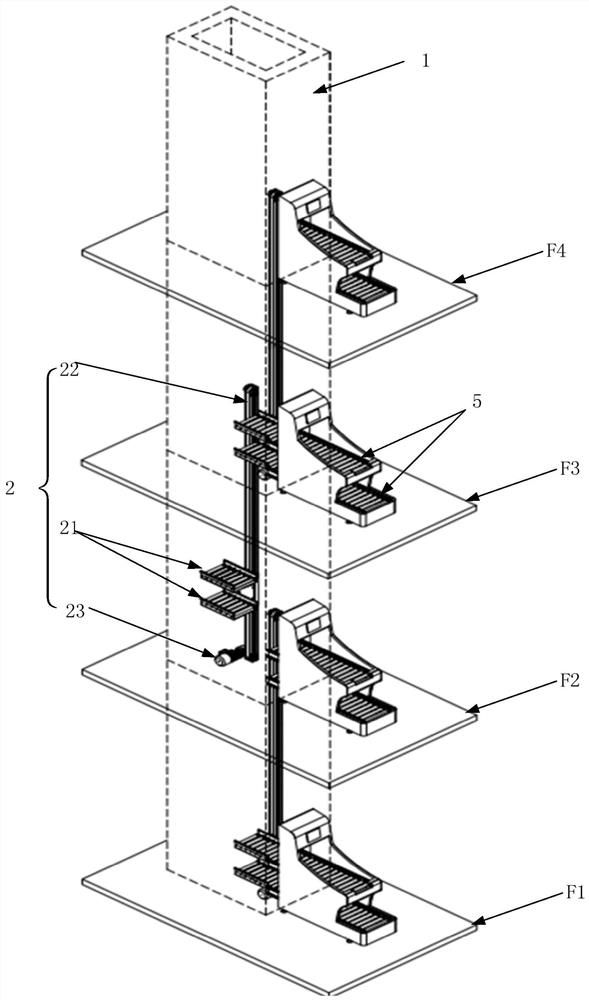

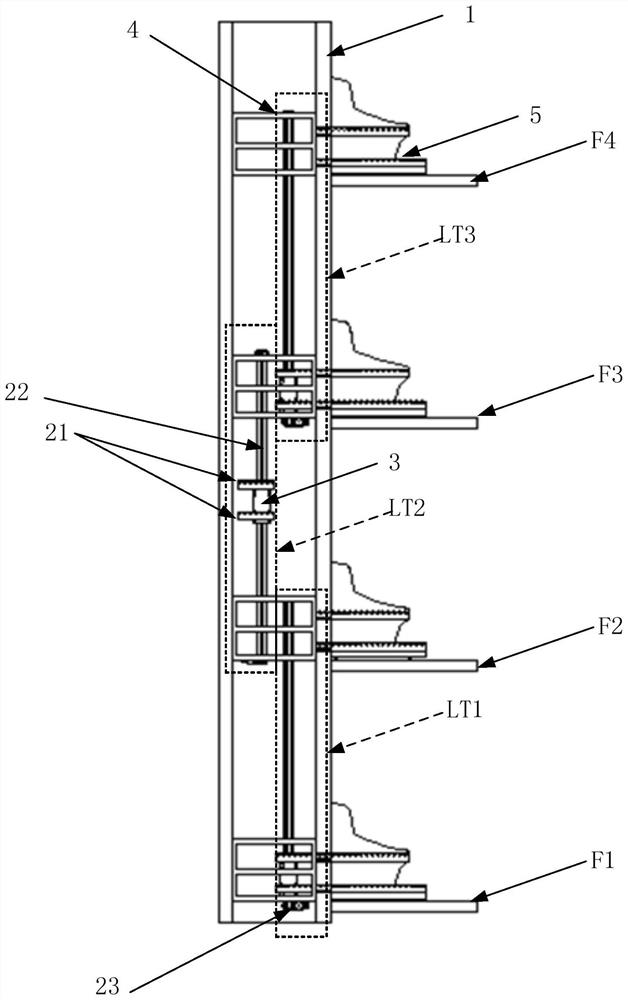

[0082] In this example, if Figure 3 to Figure 10 As shown, the task box is transported between the first floor and the sixth floor. Table 1 is the time-sequential flow chart of the relay-type vertical conveying system composed of five in-well vertical conveying modules in a six-storey building. Notes on symbols in the table: LT1, LT2, LT3, LT4, LT5 respectively represent the first to fifth in-well vertical transportation modules of the relay vertical transportation system of the present invention. F1, F2, F3, F4, F5, and F6 represent the first floor to the sixth floor respectively, and 1# box, 2# box, 3# box, 4# box, and 5# box represent 5 task boxes respectively. AT6 represents the horizontal transport module outside the well on the sixth floor.

[0083]

[0084]

[0085] Table one table two is the comparison table of the present invention and prior art:

[0086]

[0087]

[0088] Figure 11 It is a schematic diagram of the time sequence for conveying ten tas...

Embodiment 2

[0092] In this embodiment, the system of the present invention realizes simultaneous upward and downward transmission of task boxes.

[0093] At the first moment:

[0094] The slide block 3 of the vertical conveying module in the first well arrives at the first floor, and the 1# task box enters the hoistway from the first floor through the horizontal conveying module 21 in the well of the vertical conveying module in the first well; the vertical conveying module in the second and the third well Slider 3 arrives at the third floor, and the 2# task box is sent to the horizontal conveyor in the well of the vertical conveying module in the second well through the horizontal conveyor in the well of the vertical conveying module in the third well on the third floor;

[0095] At the second moment:

[0096] The sliders 3 of the vertical conveying modules in the first and second wells reach the second floor at the same time, and the vertical conveying modules in the first and second w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com