Subpackaging equipment for culture medium preparation

A culture medium preparation and subpackaging technology, which is applied in biochemical equipment and methods, biochemical cleaning devices, enzymology/microbiology devices, etc. Culture medium quality and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

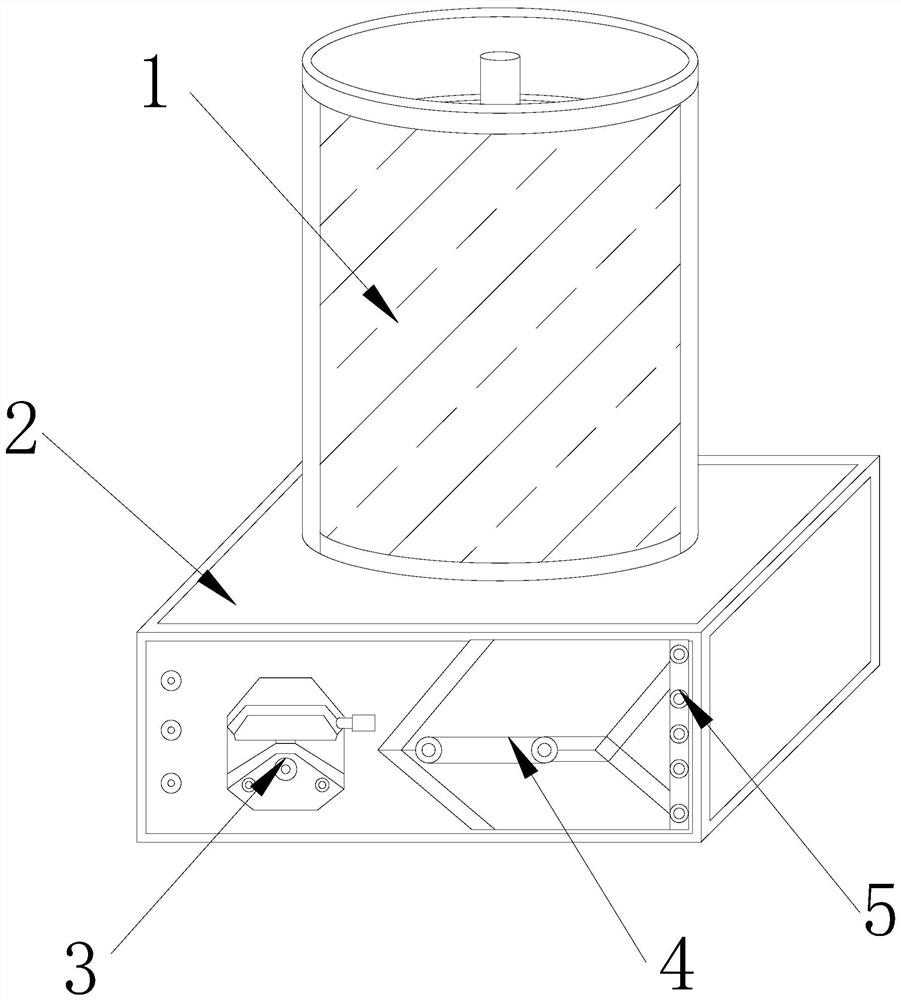

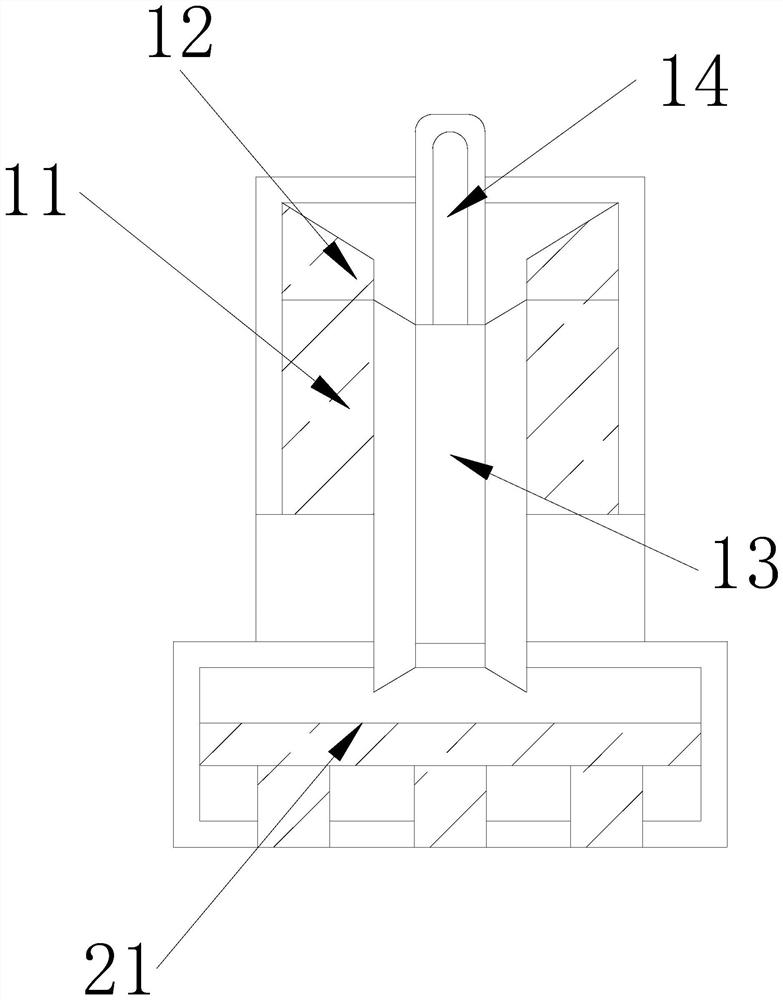

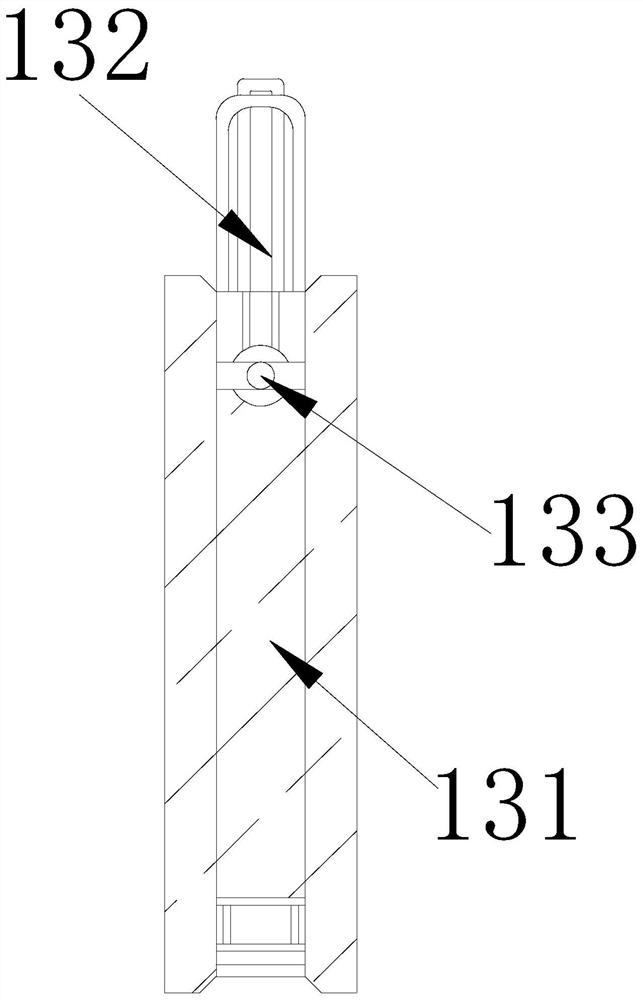

[0026]Figure 1 to 5 Down:

[0027]The present invention provides a dispensing apparatus prepared by a medium.

[0028]Its structure includes the preparation tank 1, the control station 2, the power distribution terminal 3, the flat pull shaft 4, the moving shaft 5, the lower end of the barrel 1 is connected to the console 2, and the power distribution terminal 3 is embedded in the console. 2 The left intermediate portion, the flat pull shaft 4 and the current 3 at the same axis, the movable shaft 5 to actively connect and perform a gap fit.

[0029]The barrel 1 is provided with a partition 11, a mixing end 12, a reagent passage 13, a press valve 14, and a mixing end 12 is fitted over the upper end of the partition 11, the reagent passage 13 being embedded in the center portion of the mixing end 12 and in communication. The pressing valve 14 is connected to the reagent in communication and performs a switching activity, and the console 2 is provided with a flat panel device 21, and the flat p...

Embodiment 2

[0036]Figure 6 to 8Down:

[0037]The present invention provides a dispensing apparatus prepared by a medium.

[0038]Its structure includes the tablet device 21 having a prepared base placement block 211, a pass opening 212, a conduit 213, a support block 214, and the lower end of the prepared base plate 211 is integrated with the opening port 212, the catheter 213 is mounted in the opening. On both sides of 212, the support block 214 is welded below the opening port 212, and the support block 214 is provided with three pieces below the opening port 212, and the support block 214 can effectively support each component and Maintain a balanced state so that it does not cause the liquid to be offset due to the jitter generated by the equipment.

[0039]The prepared base placement block 211 is provided with a sensor B1, a conductive line B2, a control terminal B3, a partition plate B4, a limit box B5, and the sensor B1 is equipped with a conduction line B2, the control terminal B3 and conduction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com