Energy-saving and environment-friendly cosmetic bottle drying and sterilizing device

A technology of energy saving, environmental protection and sterilization device, applied in drying, drying machine, drying solid materials, etc., can solve the problems of residual water droplets, affecting drying efficiency, and difficult to clean.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

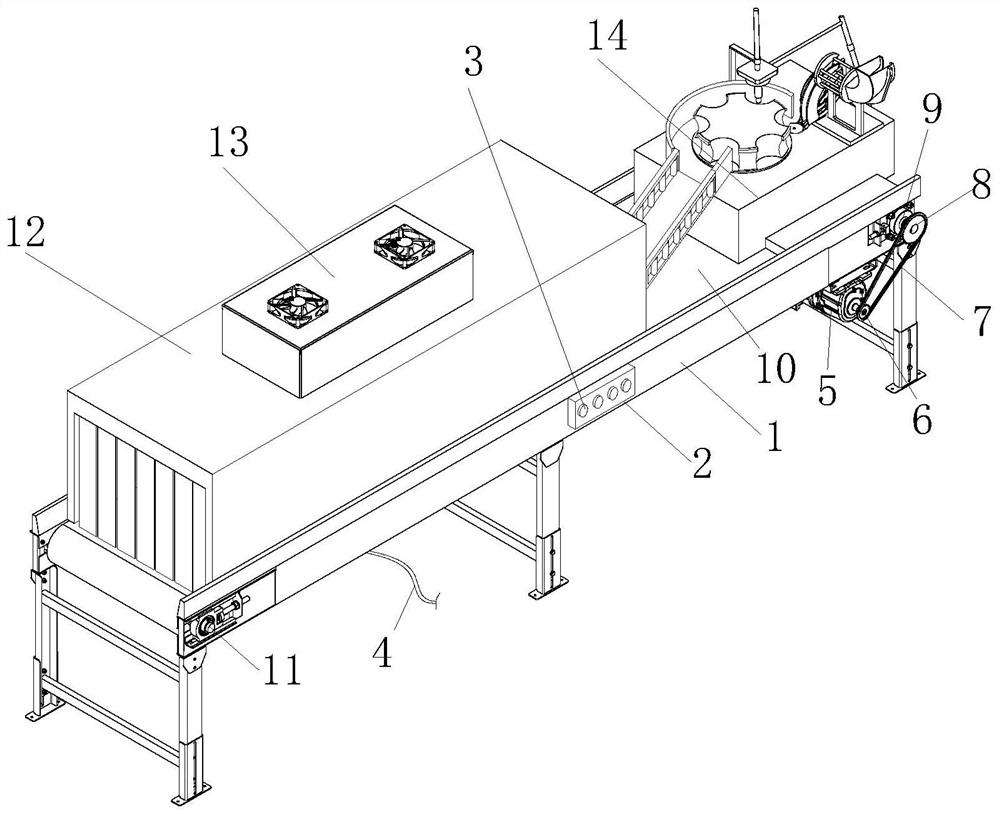

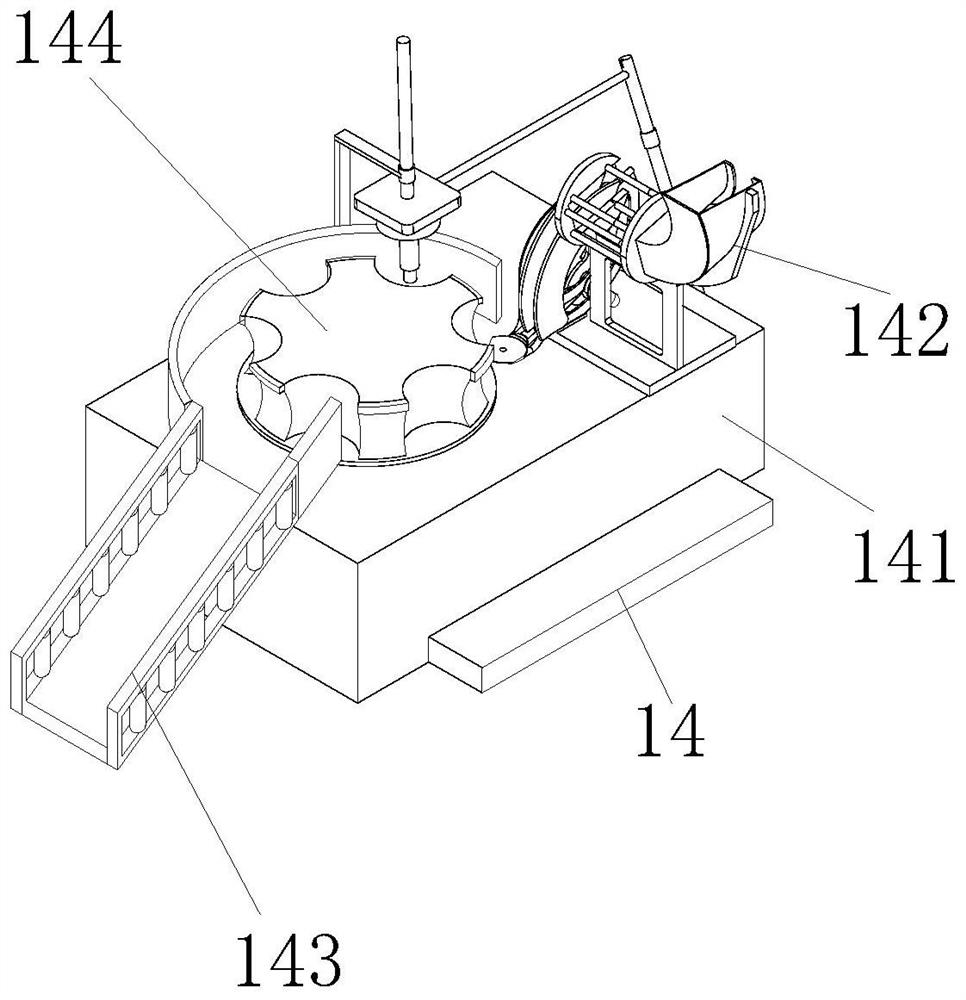

[0036] see figure 1 , the present invention provides an energy-saving and environment-friendly cosmetic bottle drying and sterilizing device through improvement, including a support frame 1, a first motor 5, a first gear 6, a transmission belt 7, a conveyor belt 10, a driven roller 11, and a drying cover 12. The dryer 13 and the intermittent conveying mechanism 14, the right end of the support frame 1 is provided with a control panel 2, the upper end of the control panel 2 is equipped with a button 3, the right end of the support frame 1 is fixed with a power wire 4, the support frame 1 and the top of the first motor 5 Bolt connection, the intermittent conveying mechanism 14 is installed and fixed on the top rear end of the support frame 1, the first motor 5 is rotationally connected with the middle part of the first gear 6, the first gear 6 is connected with the second gear 8 through the transmission belt 7, and the second gear 8 Rotately connected with the right end of the d...

Embodiment 2

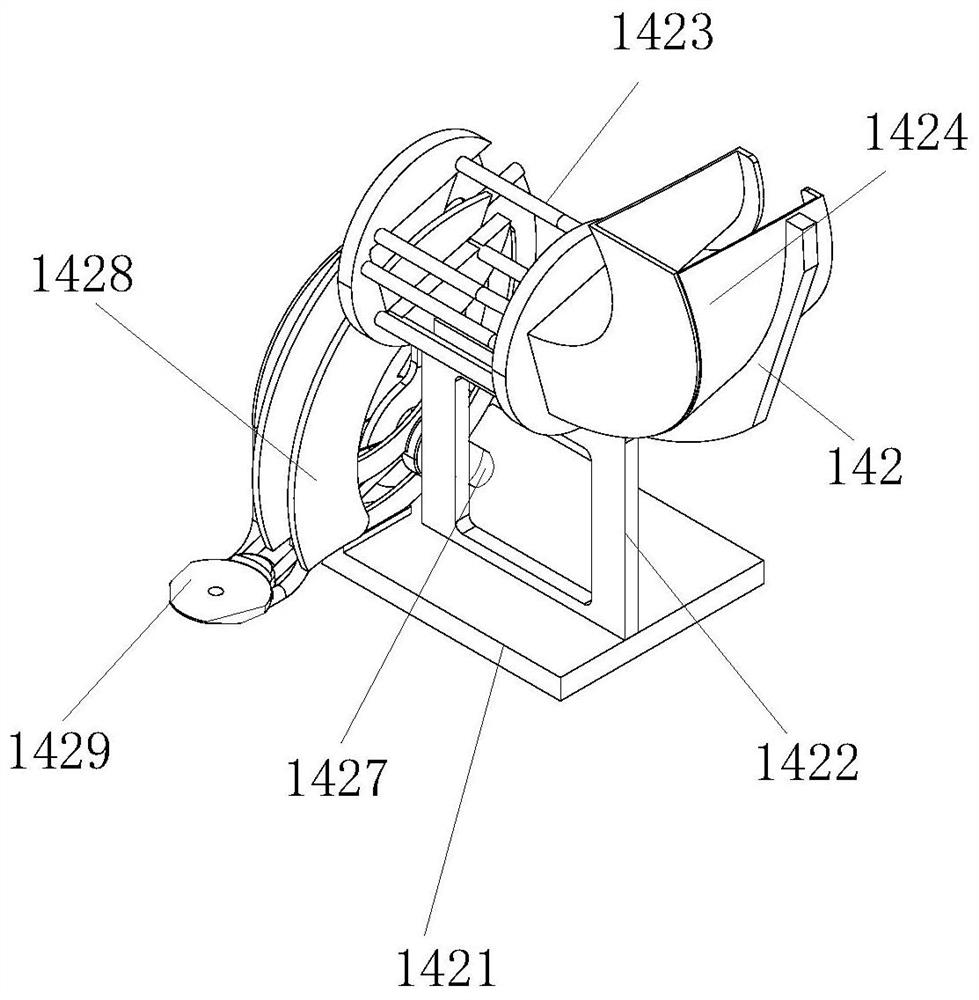

[0044] The present invention provides an energy-saving and environment-friendly cosmetic bottle drying and sterilizing device through improvement. The guide column 14446 is L-shaped, and the guide column 14446 is located at the left rear end of the arc-shaped plate 1448. The feeding plate 1428 is arc-shaped, and the feeding plate 1428 There are two sets in total, which are staggeredly distributed in the middle and rear ends of the flow guide frame 1425, and the rotation angles of the flow guide frame 1425 are both 30 degrees clockwise and counterclockwise. After the flow guide frame 1425 is rotated 30 degrees counterclockwise, the The height of the flow frame 1425 is lower than the height of the top of the flow guide frame 1425, which is conducive to transporting cosmetic bottles. The upper end of the rotating disk 1447 is provided with a toggle projection 14472, which is beneficial to dial the bottle on the upper end of the placement piece 1429. Move to the inner side of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com