Efficient zinc plating and rack plating production line and process thereof

A production line, high-efficiency technology, applied in the direction of cells, electrolysis process, electrolysis components, etc., can solve the problem of long soaking time of workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

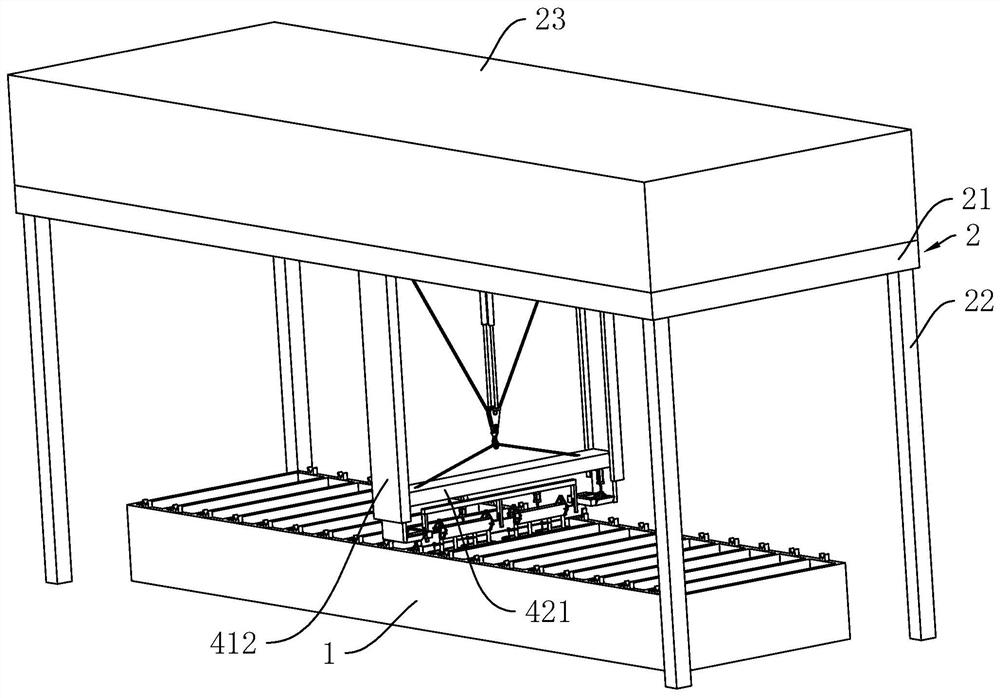

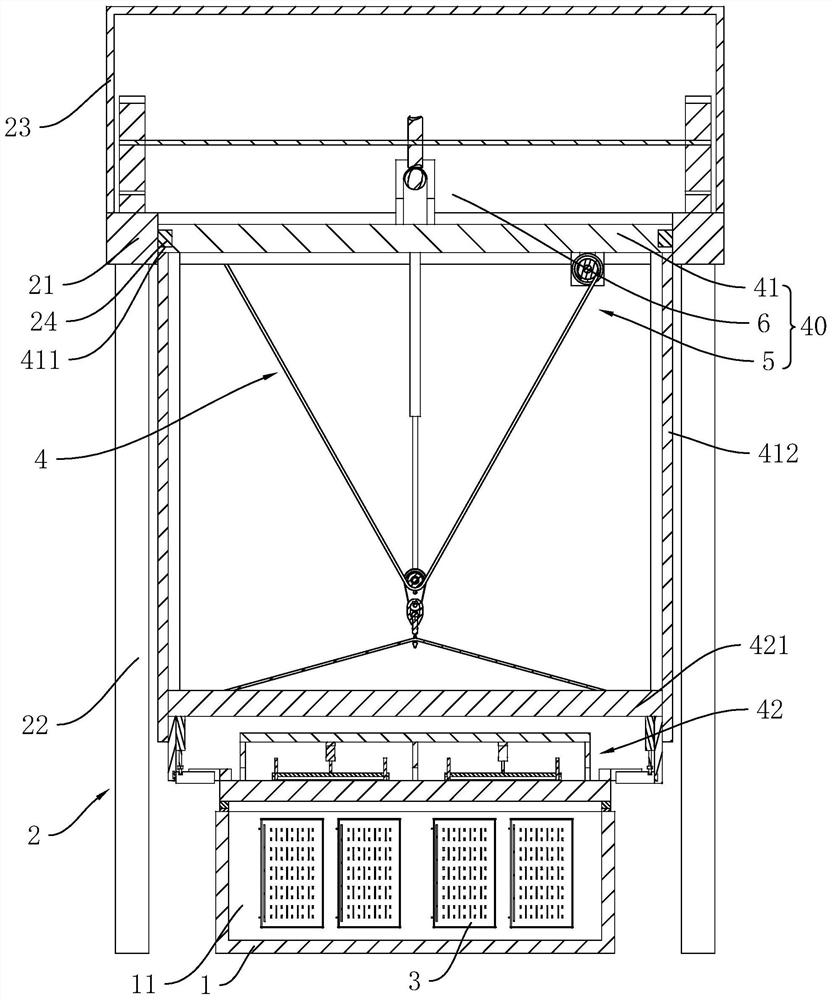

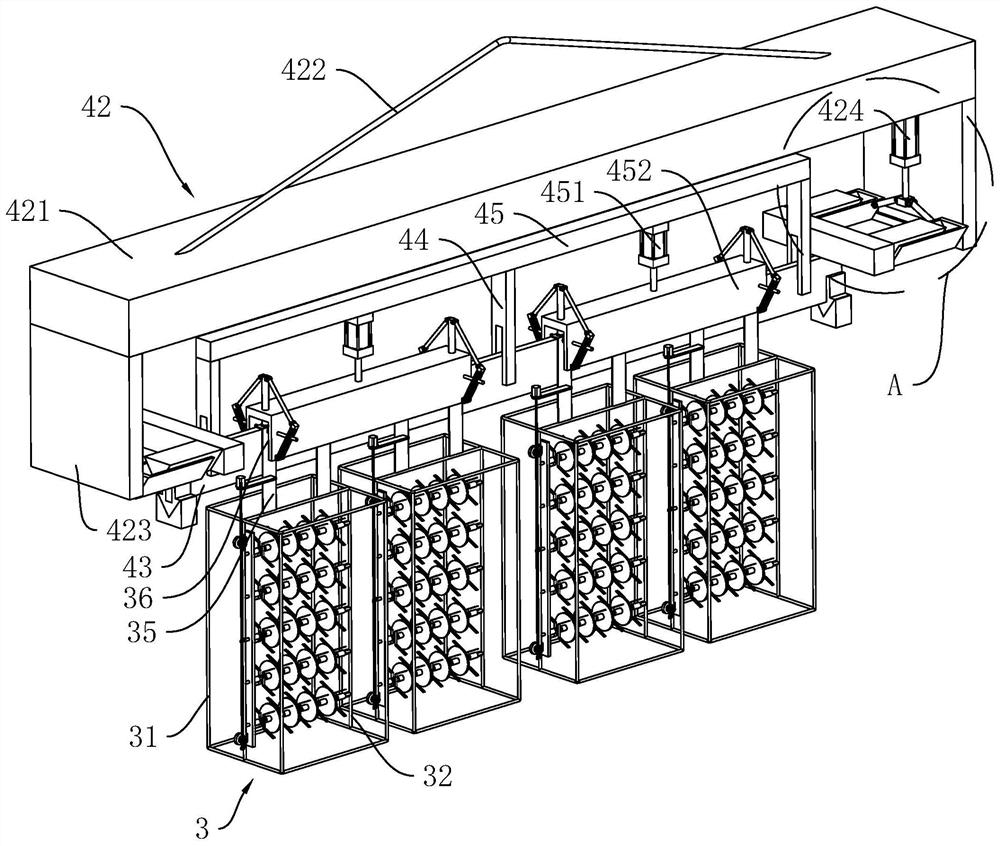

[0049] The embodiment of the present application discloses a high-efficiency galvanized rack plating production line.

[0050] refer to figure 1 and figure 2 , a high-efficiency galvanized rack plating production line includes a rack plating tank 1, a lifting frame 2 and a hanger 3, and the rack plating tank 1 is sequentially provided with several partitions 11 along the moving direction of the workpiece during rack plating, and the partitions 11 The cavity in the rack plating pool 1 is successively divided into thermal degreasing pool, primary electrolytic pool, water washing pool, acid electrolytic pool, acid degreasing pool, water washing pool, electrolytic pool, water washing pool, activation pool, water washing pool, electroplating pool, recycling pool, washing pool, pickling pool, passivation pool, washing pool, ultrasonic pool and washing pool; the lifting frame 2 is set outside the hanging plating pool 1, and the lifting frame 2 is provided with a lifting mechanism f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com