Open-web continuous beam bridge V-brace section and a construction method adapting to a soft soil foundation area

A soft soil foundation and construction method technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as adverse effects of root beams, high cost of measures, and poor landscape effect of V-braced structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

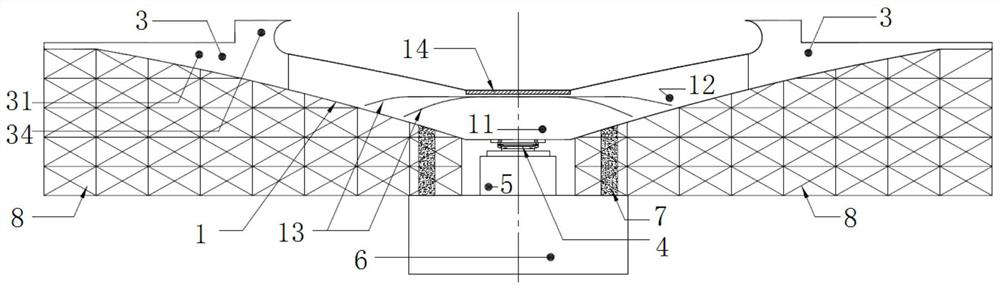

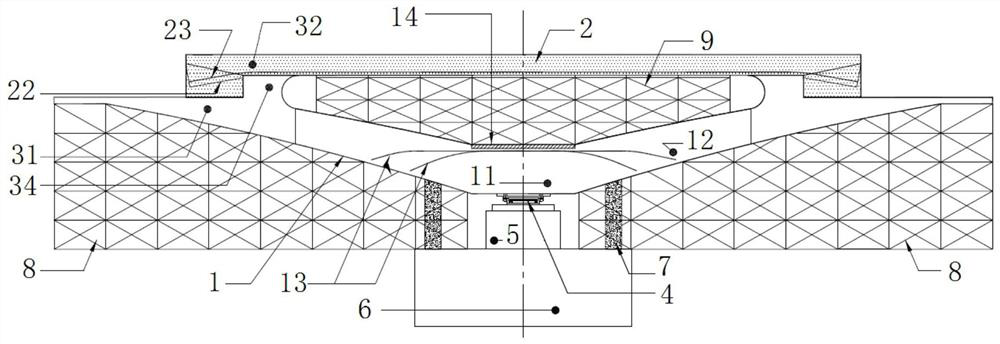

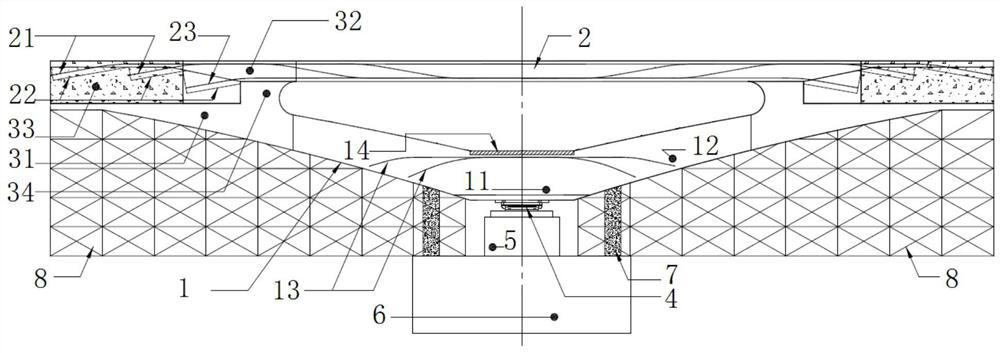

[0064] Such as image 3 As shown, the V-brace segment of the hollow continuous girder bridge includes the lower chord beam 1, the upper chord beam 2, and the outer upper and lower chord beam 3.

[0065] Among them, the upper chord beam 2 and the lower chord beam 1 are closed to form an inverted trapezoidal hollow ring structure, and there is no vertical connecting tie rod between the upper chord beam 2 and the lower chord beam 1;

[0066] The lower chord beam 1 includes a root beam 11 at the support made of ordinary concrete and a layer of ultra-high-performance concrete surface layer 14 on the top surface, and a combined cross-section structure is formed by adopting the combined structure technology of ordinary steel bars being arranged throughout and concrete being poured up and down. form, and two V-shaped bottom chords 12 respectively connected to both sides of the root beam 11 at the support and tilted upward in a V-shape;

[0067] The root beam 11 at the support and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com