Shielding frame steel mesh opening method and device, electronic equipment and storage medium

A technology of shielding frame and steel mesh, which is applied in the direction of assembling printed circuits, printed circuits, and electrical components with electrical components, which can solve the problems of hidden danger of device collision, insufficient stress of steel mesh, and difficulty in detining.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

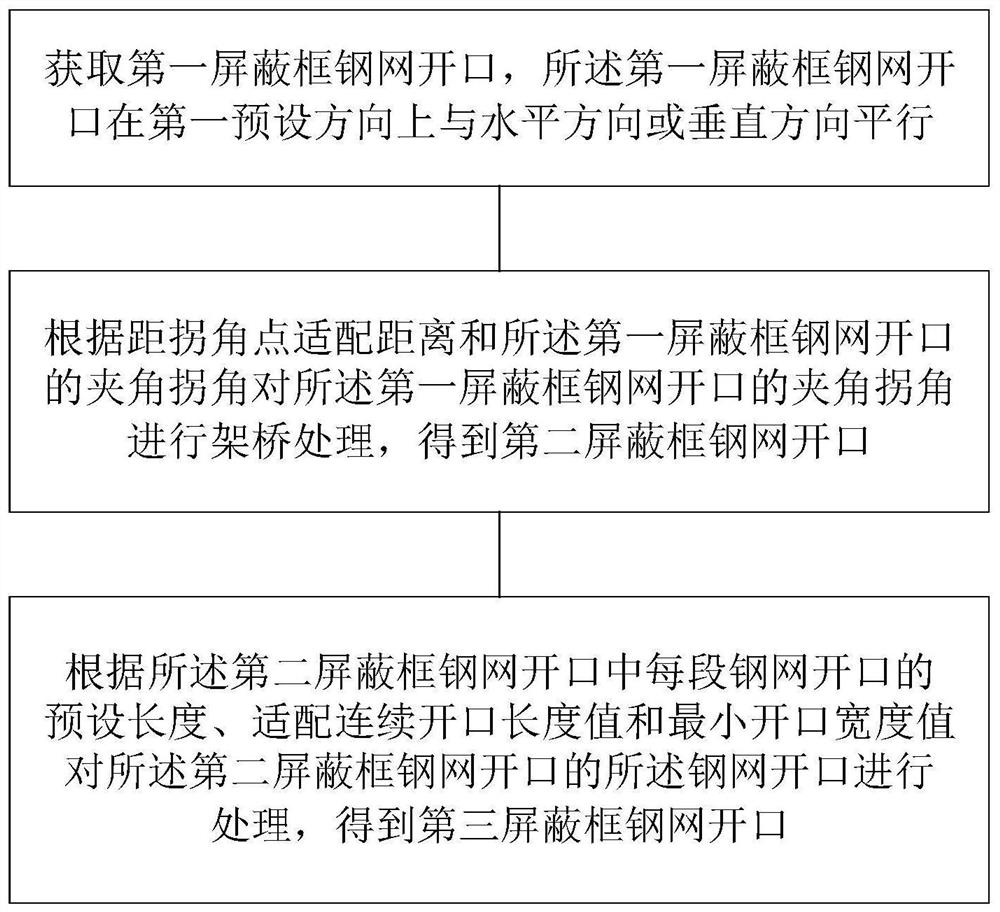

[0062] See figure 1 and figure 2 , figure 1 It is a schematic flow chart of a method for opening a shielding frame stencil provided by an embodiment of the present invention, figure 2 It is a schematic flow chart of another method for opening a shielding frame stencil provided by an embodiment of the present invention. This embodiment provides a method for opening a shielding frame stencil. The method for opening a shielding frame stencil may include steps 1 to 3, wherein :

[0063] Step 1. Obtain the opening of the steel mesh of the first shielding frame, and the opening of the steel mesh of the first shielding frame is parallel to the horizontal direction or the vertical direction in a first preset direction.

[0064] Specifically, the size of the steel mesh opening of the first shielding frame should be able to meet the welding quality, and the steel mesh opening of the first shielding frame is parallel to the horizontal direction or the vertical direction in the first...

Embodiment 2

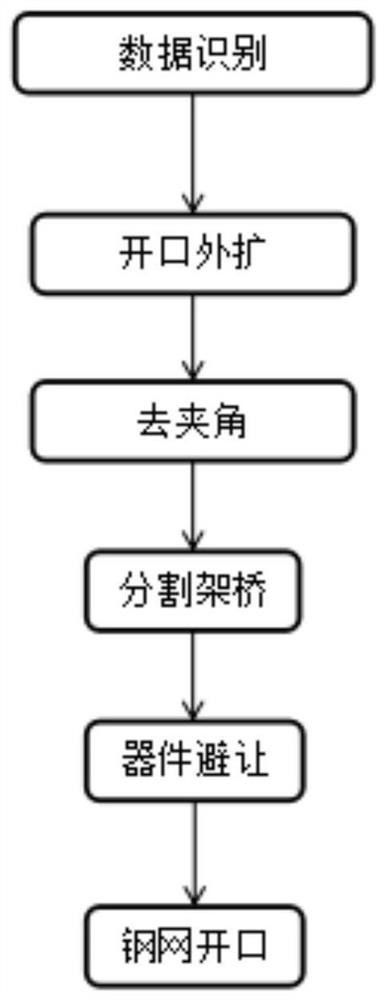

[0117] In order to better understand the shielding frame steel mesh opening method provided by the present invention, a specific shielding frame steel mesh opening method is also provided on the basis of the above embodiments, the shielding frame steel mesh opening method includes:

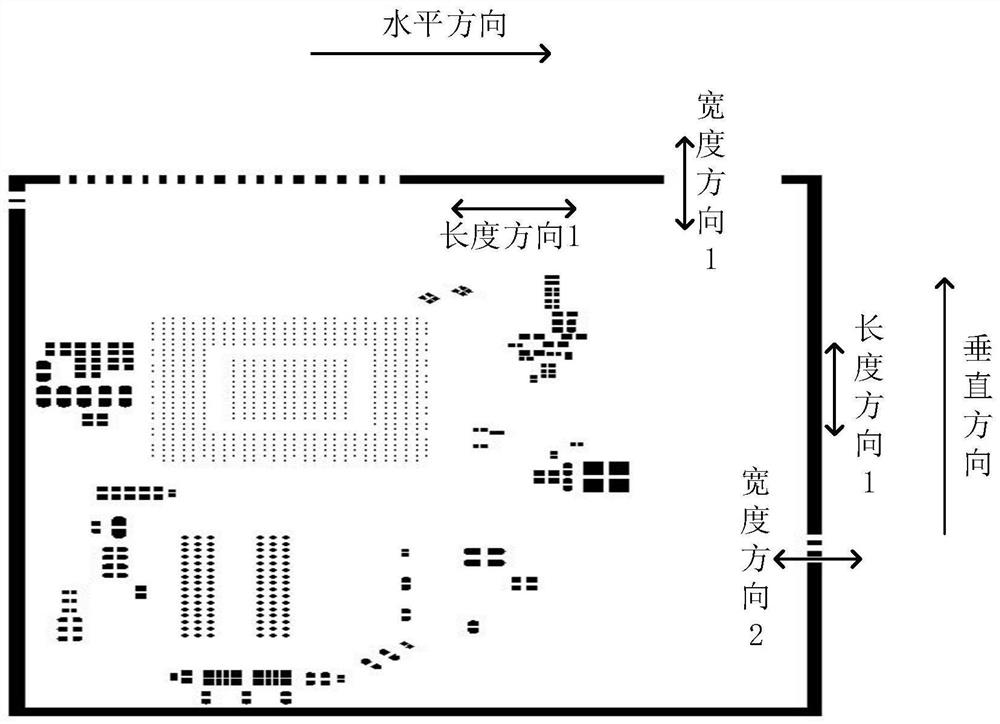

[0118] S1. Obtain all pad information from PCB design data, including device coordinates, outer frame, image information, etc. Take out the pad information of the shielding frame. Since the pads of the shielding frame in this example are in a horizontal state, there is no need to perform zeroing processing, or the zeroing rotation angle is 0 degrees. Set the processed pad information of the shielding frame as Preset shielding frame stencil openings.

[0119] S2. In the width direction, expand the acquired preset shielding frame stencil opening by 0.1 mm along the inside and outside respectively, so as to update the preset shielding frame steel mesh opening.

[0120]S3. Take out the coordinates of...

Embodiment 3

[0133] See Figure 17 , Figure 17 It is a schematic structural diagram of a shielding frame steel mesh opening device provided by an embodiment of the present invention. The shielding frame stencil opening device includes:

[0134] An acquisition module, configured to acquire the steel mesh opening of the first shielding frame, where the steel mesh opening of the first shielding frame is parallel to the horizontal direction or the vertical direction in the first preset direction;

[0135] The first bridging processing module is configured to perform bridging processing on the included corner of the steel mesh opening of the first shielding frame according to the fitting distance from the corner point and the included corner of the steel mesh opening of the first shielding frame to obtain the second shielding frame Stencil opening;

[0136] The second bridging processing module is used to adjust the stencil of the second shielding frame stencil opening according to the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com