Electric propeller with two usable faces

An electric propulsion, double-sided technology, applied in the direction of ship propulsion, propulsion components, electric components, etc., can solve problems affecting the propulsion energy efficiency of the propeller, and achieve the effect of improving propulsion efficiency and reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

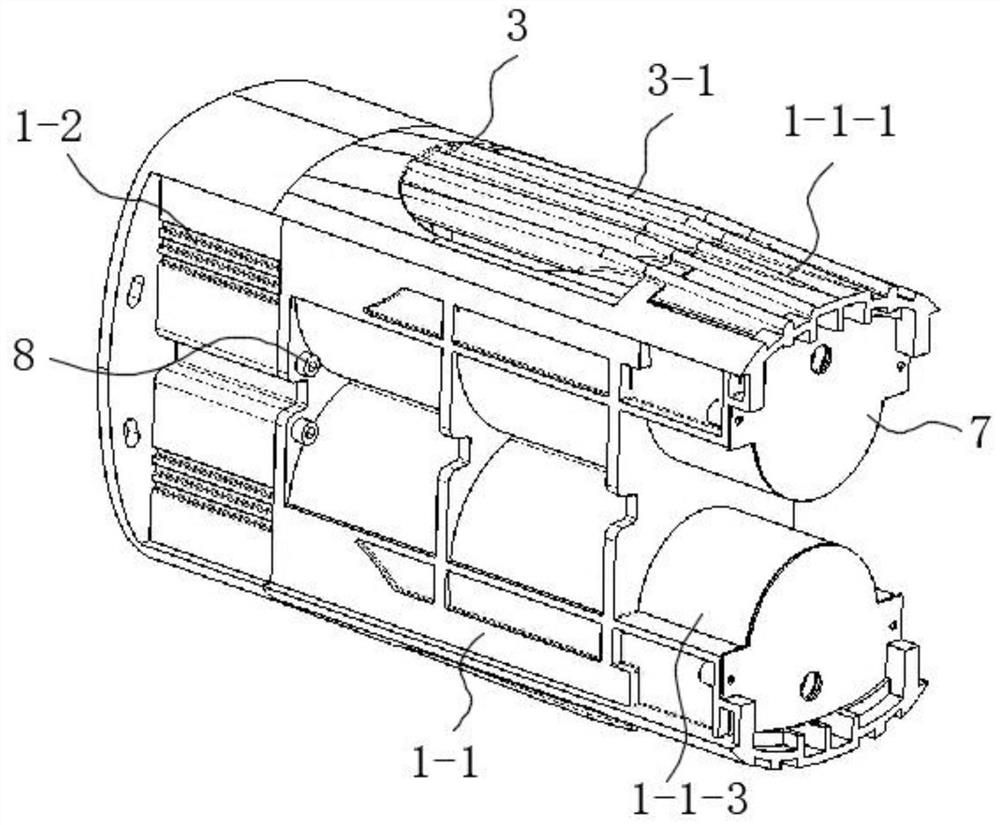

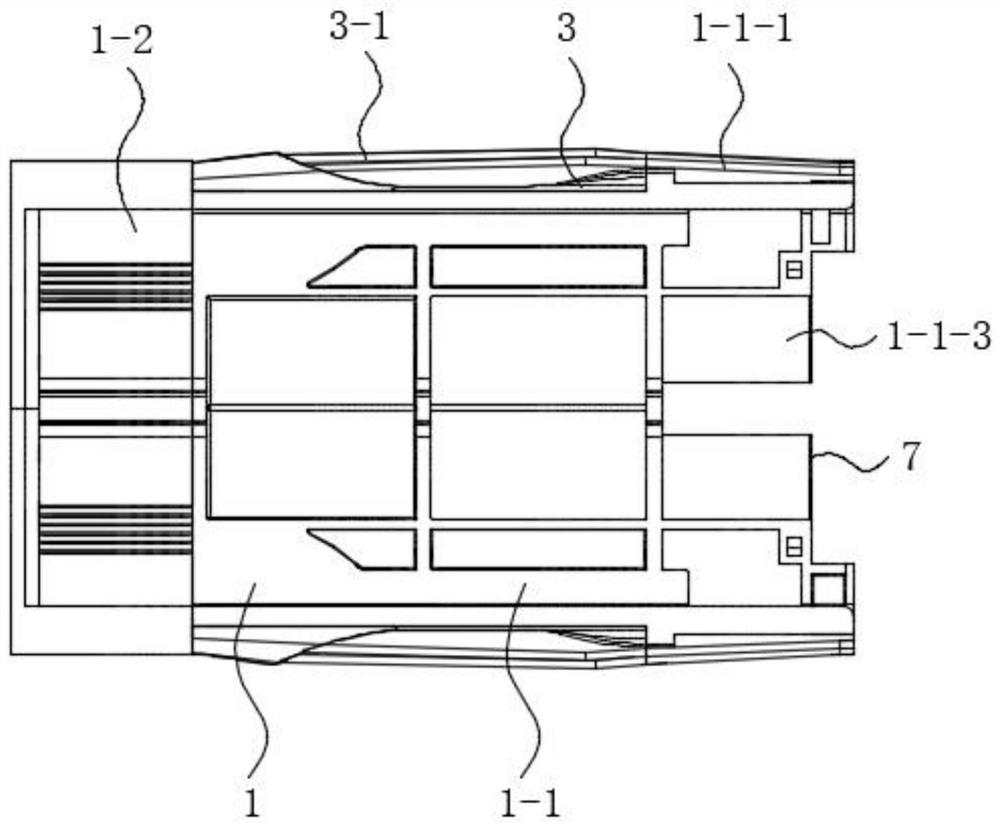

[0038] A double-sided electric propeller includes a body frame 1 as an installation base, the body frame 1 is composed of a front frame 1-1 and a rear frame 1-2, and the front frame 1-1 and the rear frame 1-2 The composition is fixed by screws 8;

[0039] The upper and lower sides of the front frame 1-1 are symmetrically integrally formed with a main channel 1-1-2, and the side of the front frame 1-1 away from the rear frame 1-2 is symmetrically provided with a motor installation cavity 1-1-3, And the outside of the main channel 1-1-2 is open and provided with a water inlet for liquid medium input, and a water inlet grill 3 is arranged on the water inlet;

[0040] The upper and lower sides of the rear frame 1-2 are symmetrically provided with contraction nozzles 1-2-1, and the stator blades 1-2-2 for reinforcement are fixedly installed in the contraction nozzles 1-2-1;

[0041] A motor 2 for generating power is provided in the two motor installation cavities 1-1-3, and the mo...

Embodiment 2

[0045] The difference between this embodiment and embodiment 1 is that, as Figure 6-8 As shown, the side of the water inlet grille 3 close to the front frame 1-1 is symmetrically provided with a first boss 3-2 for positioning, and the front frame 1-1 is symmetrically provided with the first boss 3-2. 2 first grooves 1-1-4 engaged with each other; the side of the rear frame 1-2 close to the water inlet grille 3 is symmetrically provided with a second boss 1-2-3 for positioning, and the water inlet The grid 3 is symmetrically provided with a second groove 3-1 engaging with the second boss 1-2-3;

[0046] In this embodiment, the first boss 3-2 is engaged with the first groove 1-1-4, and the second boss 1-2-3 is engaged with the second groove 3-1, effectively ensuring the water inlet Stable installation of grille 3.

Embodiment 3

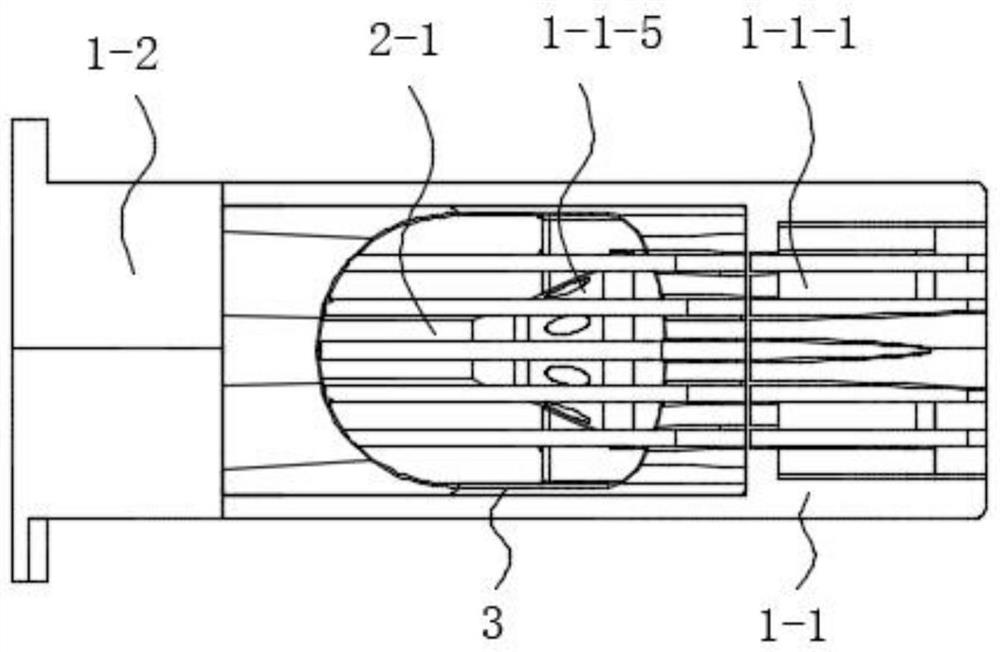

[0048] The difference between this embodiment and embodiment 1 is that, as Figure 4-6 As shown, the side of the main channel 1-1-2 close to the motor installation position is integrally formed with a shaft sleeve part 1-1-5 sleeved on the motor shaft 2-1, and the shaft sleeve part 1-1-5 is There are multiple flow channels connected with the motor installation cavity 1-1-3;

[0049] In this embodiment, the fluid medium passes through the motor installation chamber 1-1-3, so that the heat from the motor 2 in the motor installation chamber 1-1-3 is transferred away, which is beneficial to the heat dissipation of the motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com