Cloth bag seal sewing machine

A technology for sewing machines and cloth bags, which is applied to pocket sewing machines, sewing machine components, needle holders for sewing machines, etc., can solve problems such as affecting the shape, and achieve the effects of preventing expansion, preventing excessive sliding and pulling, and increasing friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

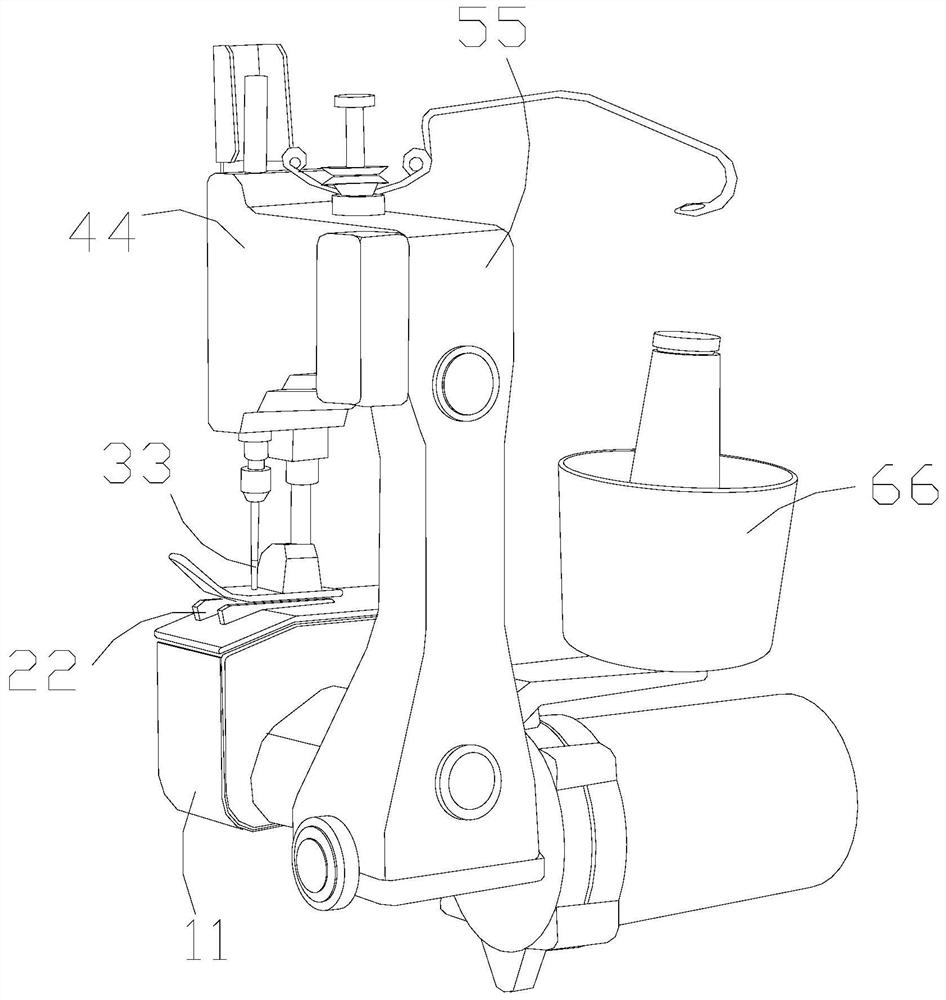

[0032] as attached figure 1 to attach Image 6 Shown:

[0033] The present invention provides a cloth bag sealing sewing machine, the structure of which includes a spacer bottom 11, a bracket 22, a sewing head 33, an impact box 44, a support frame 55, and a thread barrel 66, and the lower surface of the bracket 22 is welded to the spacer bottom 11. On the upper surface, the sewing head 33 is installed inside the lower end of the impact box 44 , the impact box 44 is welded to the outer surface of the support frame 55 , and the thread barrel 66 is located at the side of the support frame 55 .

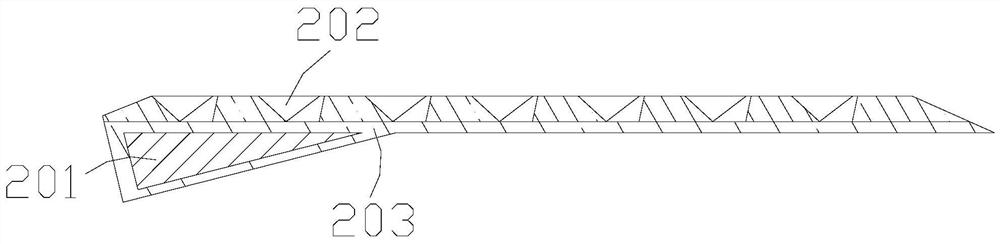

[0034] The bracket 22 includes a support block 201 , a socket 202 , and a partition 203 , the support block 201 is embedded in the partition 203 , and the socket 202 is installed on the upper surface of the partition 203 .

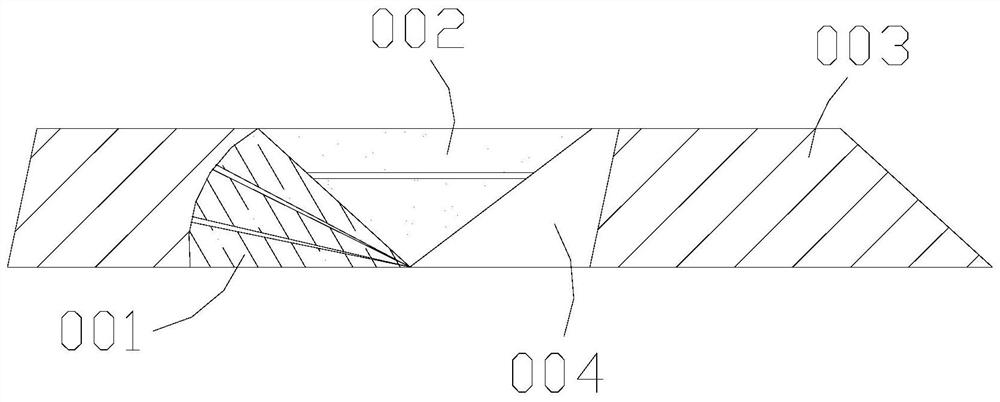

[0035] Wherein, the bracket 202 includes a fan 001, a corner 002, a spacer 003, and an opening 004. The fan 001 is attached to the outer surface of the corner 002, ...

Embodiment 2

[0042] as attached Figure 7 to attach Figure 9 Shown:

[0043]Wherein, the sewing head 33 includes an abutment angle 301, a moving block 302, a needle body 303, and a spring 304. The abutment angle 301 and the moving block 302 are an integral structure, and the spring 304 is embedded in the inside of the needle body 303. The lower part of the spring 304 is connected with the moving block 302, and the abutting angle 301 is distributed around the outside of the needle body 303, and the moving block 302 is connected between the force-bearing part and the fixed part to play the role of a central drive, and the abutting angle 301 is in contact with foreign objects, and it is pressed and fixed.

[0044] Wherein, the abutment angle 301 includes a pressing head m01 and a hard angle m02, the outer surface of the hard angle m02 is connected with the pressing head m01, the hard angle m02 has a triangular structure, and the pressing head m01 is connected with the foreign object The c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap