500kV line tension-resistant iron tower with 180-degree rotation angle

A technology of turning angle and line, which is applied to the installation of towers, building types, cables, etc., can solve the problems of incomplete erection and difficulty in erecting corner towers, shorten the length of erection path, reduce the cost of erection manpower and material resources, and protect nature environmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

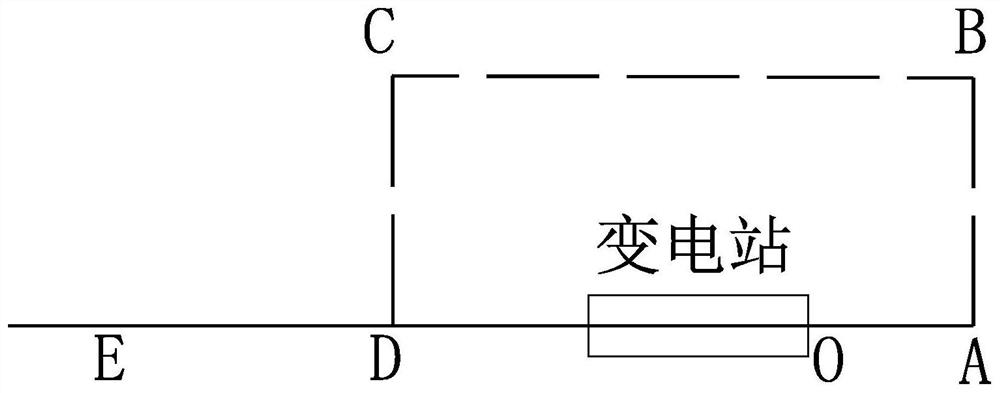

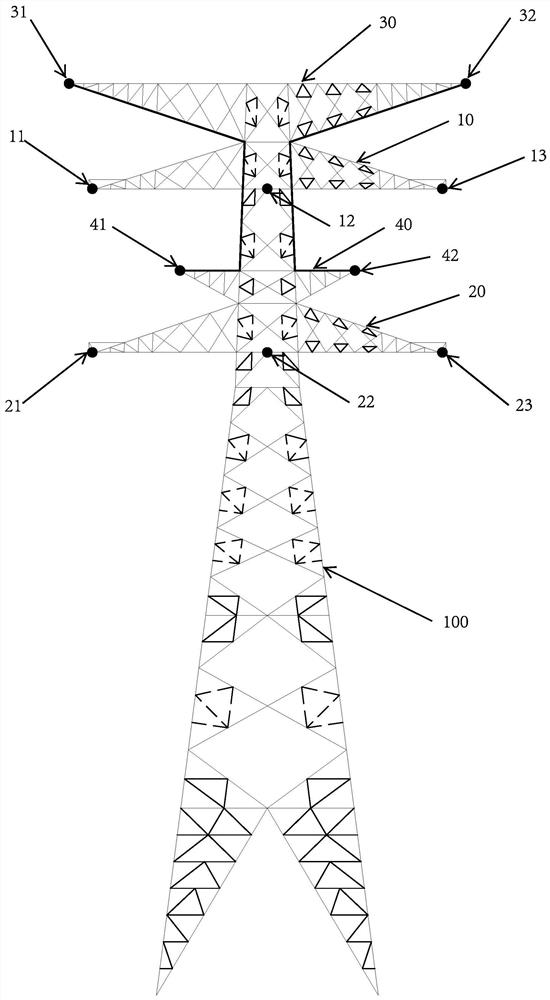

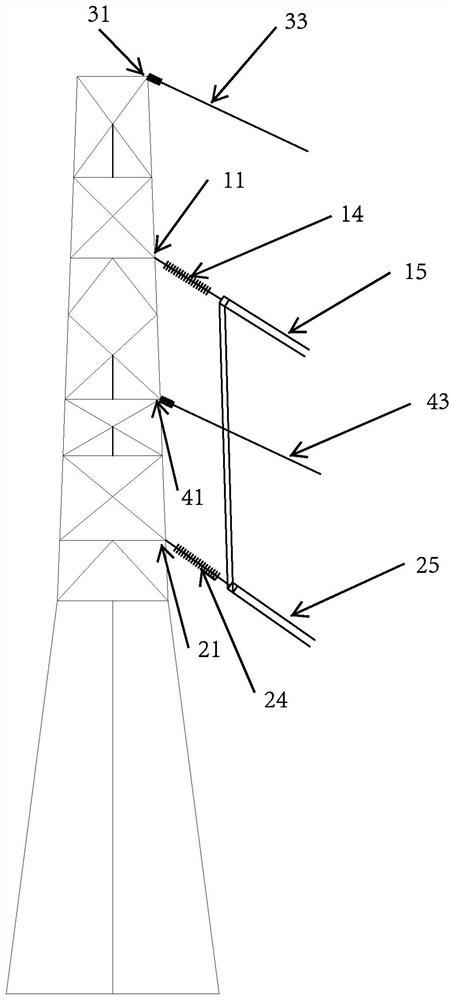

[0025] Below in conjunction with the accompanying drawings, a 500kV line tension type iron tower with an angle of rotation of 180° proposed according to the present invention, its specific implementation, structure, features and effects are described in detail as follows:

[0026] like figure 2 As shown in the figure, a 500kV line tension type iron tower with a turning angle of 180 degrees of the present invention has a tower body 100, which is characterized in that the tower body 100 is provided with a left-right symmetrical upper wire cross-arm 10 and a lower wire cross-arm in parallel up and down. Bear 20. Wherein, the left and right ends of the upper-layer wire cross-arm 10 are respectively provided with a first upper-layer wire hanging point 11 and a third upper-layer wire hanging point 13, and the first upper-layer wire hanging point 11 and the third upper-layer wire hanging point 13 are horizontal The heights are the same, and a second upper-layer wire hanging point 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com