Diesel engine test run cooling system and multi-hot-water-pump linkage control device thereof

A technology for cooling systems and hot water pumps, applied in pump control, non-electric variable control, liquid level control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

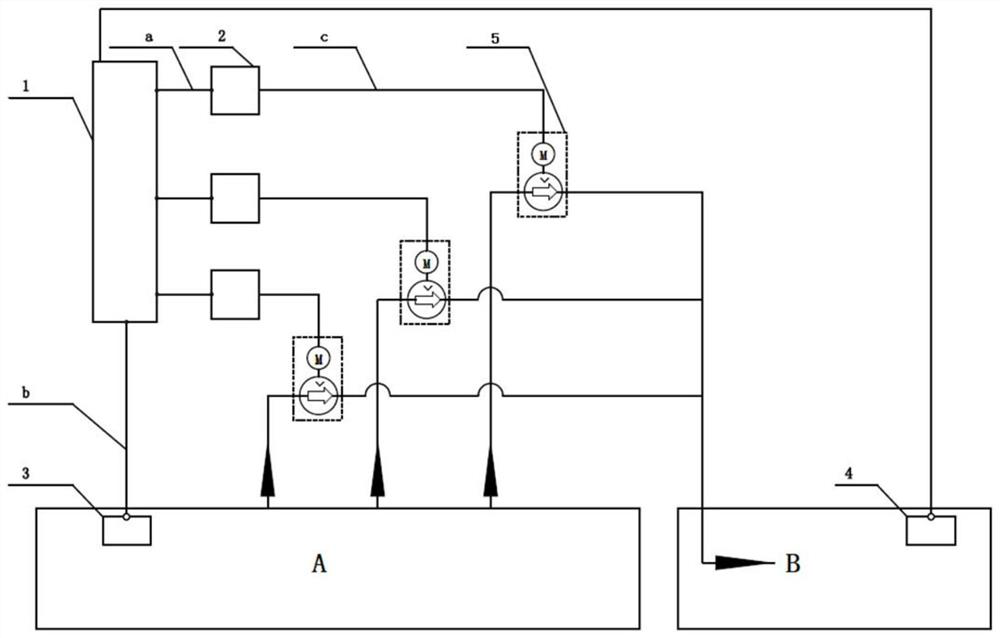

Image

Examples

Embodiment Construction

[0025] The following is a detailed description of the embodiments of the present invention: this embodiment is implemented on the premise of the technical solution of the present invention, and provides detailed implementation methods and specific operation processes. It should be noted that those skilled in the art can make several modifications and improvements without departing from the concept of the present invention, and these all belong to the protection scope of the present invention.

[0026] An embodiment of the present invention provides a multiple hot water pump linkage control device for diesel engine test run, including multiple frequency converters, PLC controllers, first liquid level sensors, and second liquid level sensors that are arranged in cooperation with each hot water pump sensor; where:

[0027] Each of the frequency converters is connected to a PLC controller respectively;

[0028] The first liquid level sensor is installed in the hot water pool, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com