Full-automatic concrete impermeability detection system

A detection system, concrete technology, applied in the direction of measuring device, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the problems of difficult removal of concrete specimens, low work efficiency, high labor intensity, etc., to reduce the test The effect of low cost, fast running speed and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

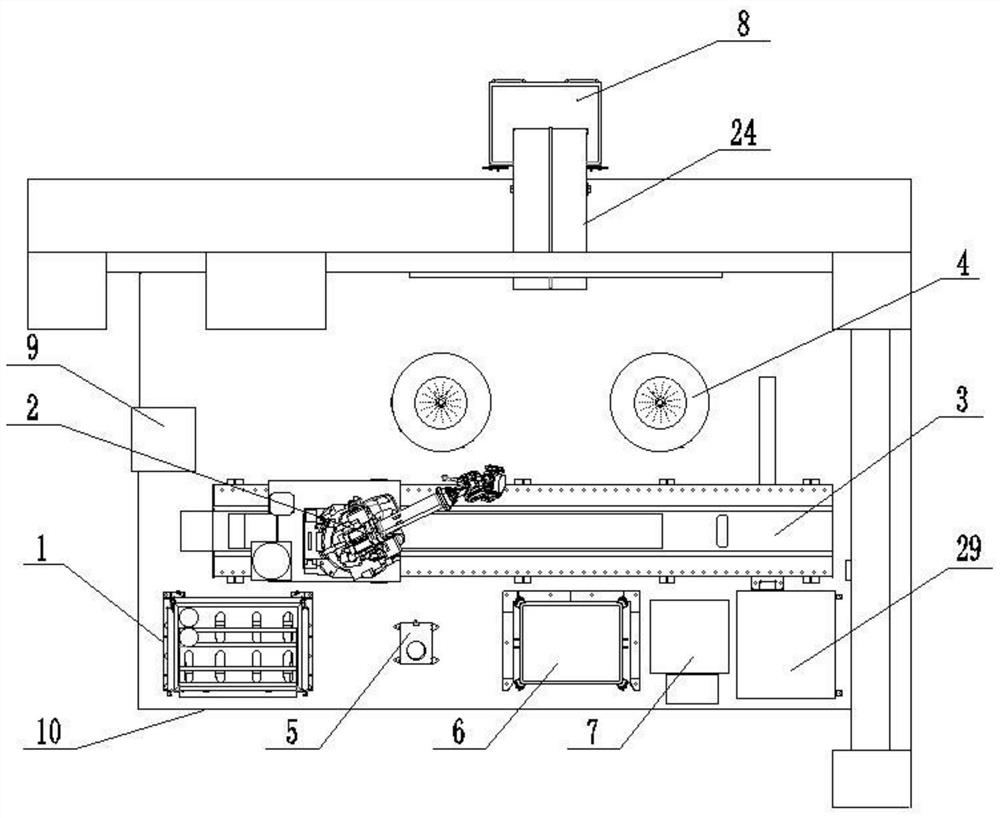

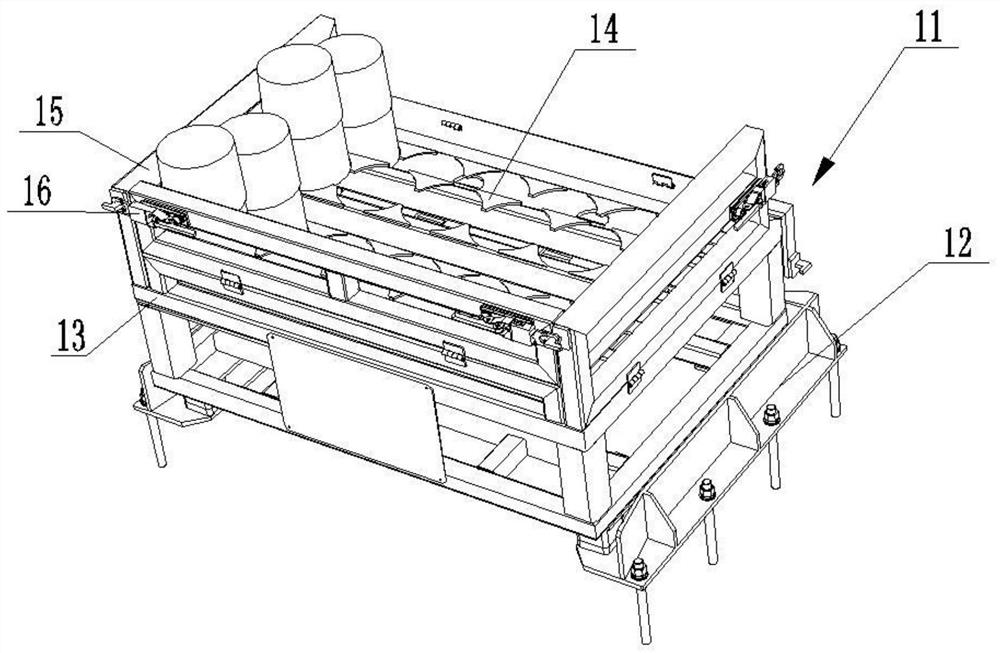

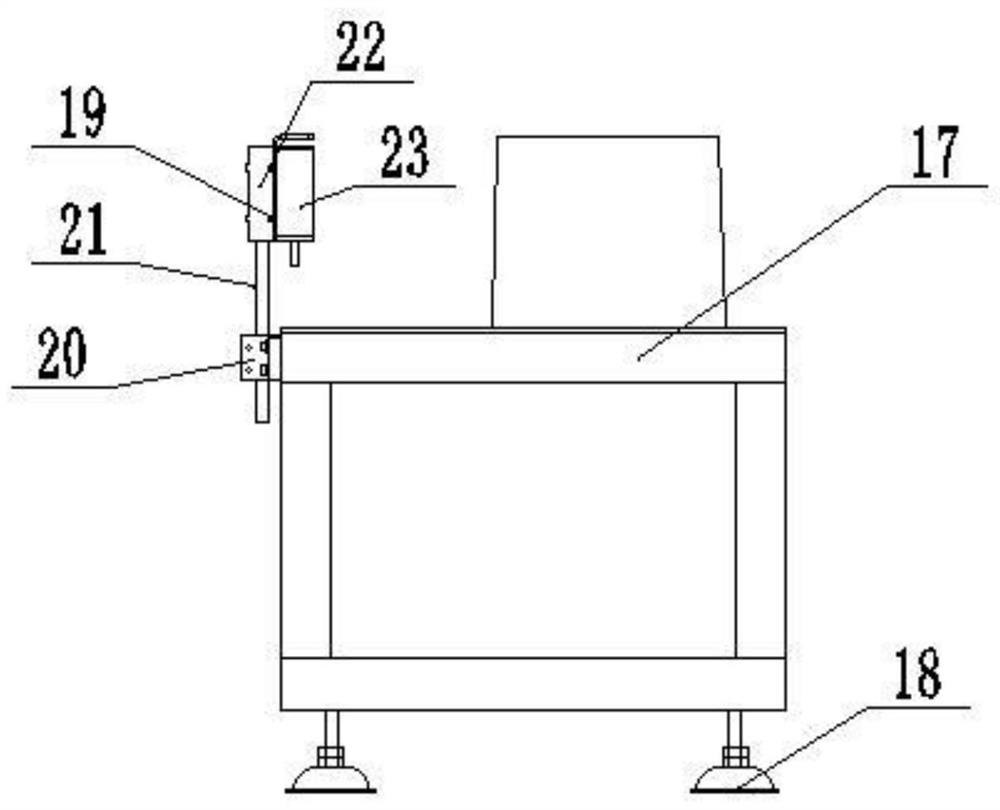

[0032] like Figure 1-Figure 4 The full-automatic concrete anti-seepage detection system shown includes a box to be inspected 1, a robot 2, a ground rail 3, an anti-seepage instrument 4, a code scanning mechanism 5, a sample retention box 6, a waste collection device, and a platform for placing code scanning failures 7 and program control cabinet 9,

[0033] The robot 2 is slidably connected to the ground rail 3, and includes a rotatable telescopic arm and its end effector. The end effector includes a clamping mechanism and a suction nozzle; the clamping mechanism is used to clamp the test piece, and the suction nozzle is used to Suck away the debris in the impermeability tester;

[0034] The box to be inspected 1, the code scanning mechanism 5, the sample retention box 6, the code scanning failure placement platform 7, the anti-seepage instrument 4 and the waste collection device are arranged on both sides of the ground rail and within the range of movement of the end effect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com