Touch sensing module, touch display device and manufacturing method thereof

A touch display device and touch sensing technology, applied in the fields of instruments, computing, electrical and digital data processing, etc., can solve problems such as damage, unusability, and changing the surface resistance value of metal grids, so as to prevent reactions and reduce vulcanization reactions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention.

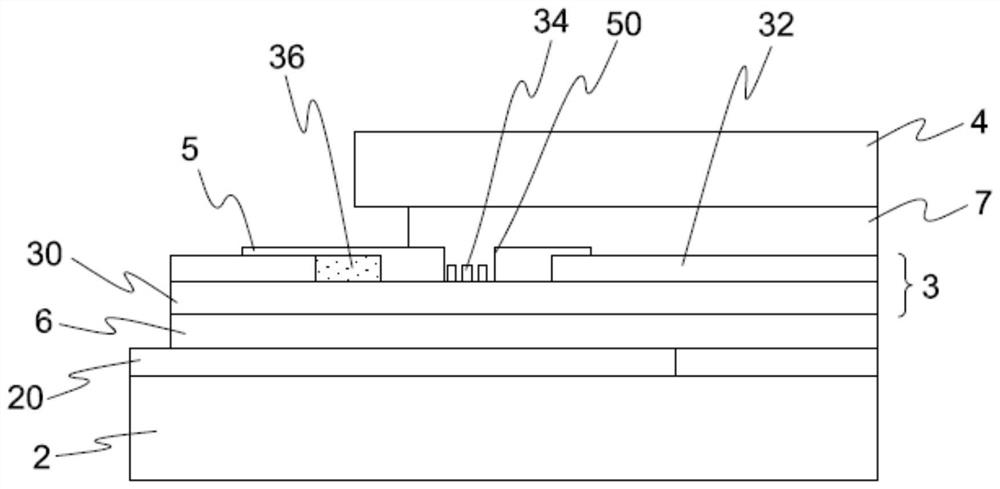

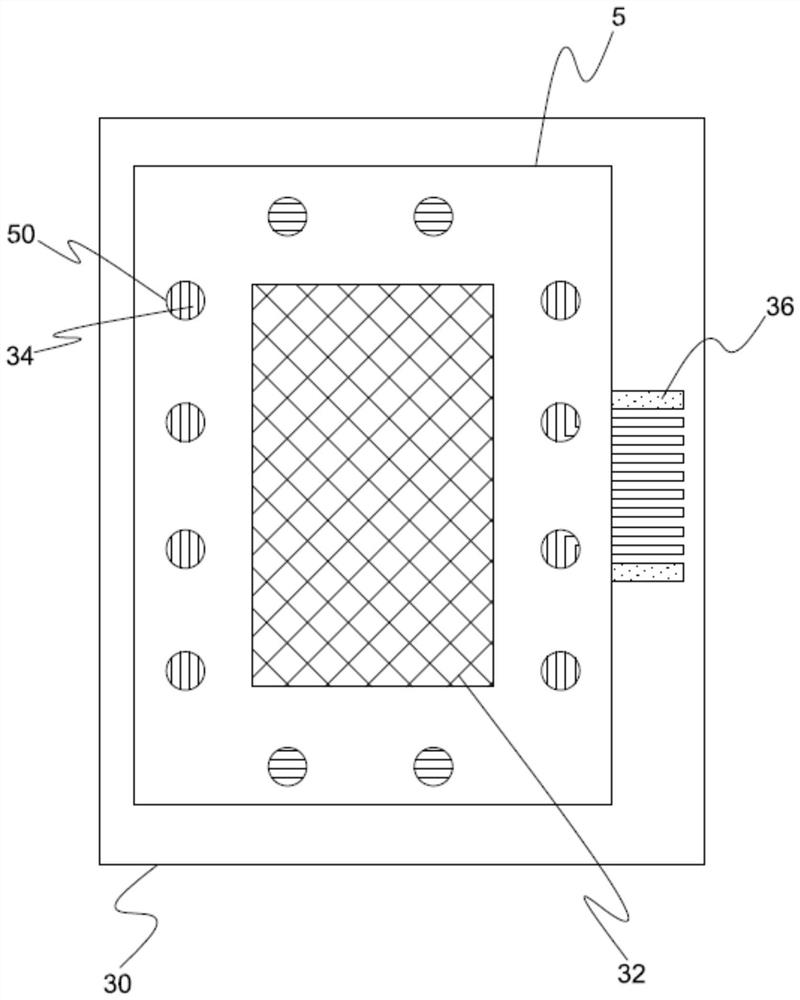

[0036] see figure 2 and image 3As shown, the present invention is a touch display device, including a cover plate 2 (Cover Lens), a touch sensing module 3, a display module 4 (for example: a liquid crystal display module 4), an insulating layer 5, a first connection layer 6 and the second connection layer 7, wherein the first connection layer 6 is disposed between the cover plate 2 and the touch sensing module 3, and the second connection layer 7 is disposed between the touch sensing module 3 and the display module 4 . The first connection layer 6 and the second connection layer 7 are opti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com