Permanent magnet type switched reluctance motor and control method thereof

A switched reluctance motor and control method technology, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit, electric components, etc., can solve the problems of high paste strength requirements, waste of internal space of the motor, and low efficiency of the motor, and achieve Less demagnetization, easier design, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

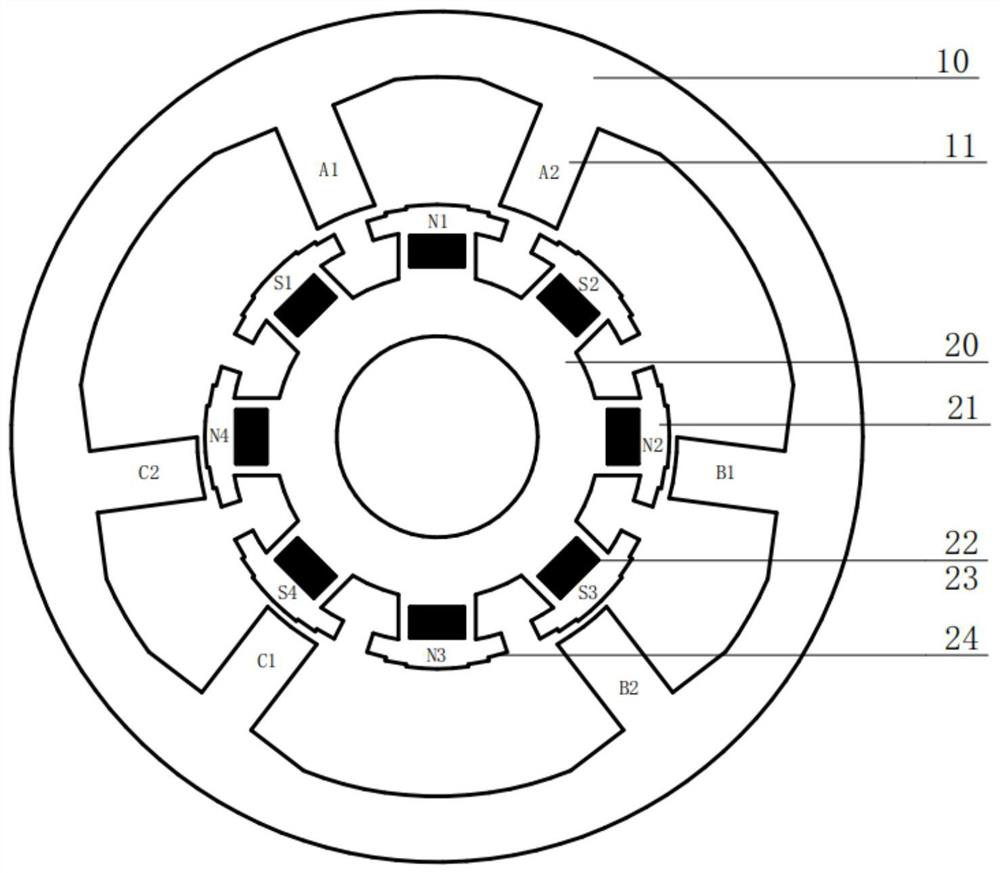

[0043] see figure 1 , a permanent magnet switched reluctance motor, comprising a stator core 10 and a rotor core 20, the number of phases of the motor is 3, the number of salient poles of the stator core 10 is 6, and the number of groups k=1; On the stator core 10, the salient poles 11 of the stator cores belonging to the same phase are arranged adjacent to each other, as shown in the figure, the salient poles 11 of the stator core belonging to the A phase are arranged adjacently and concentrated, and the stator cores belonging to the B phase The salient poles 11 of the core are arranged adjacent to each other, and the salient poles 11 of the stator core belonging to the C phase are arranged adjacent to each other, and the phase winding is installed so that the adjacent salient poles in the phase are under the action of the exciting current. Form adjacent pairs of magnetic poles; the number of salient poles of the rotor core 20 is 8, and an axial through hole 23 is arranged in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com